Why does my Hydro-Gear Lawn Mower Accessories unit have no/low power?

- UuwilliamsAug 16, 2025

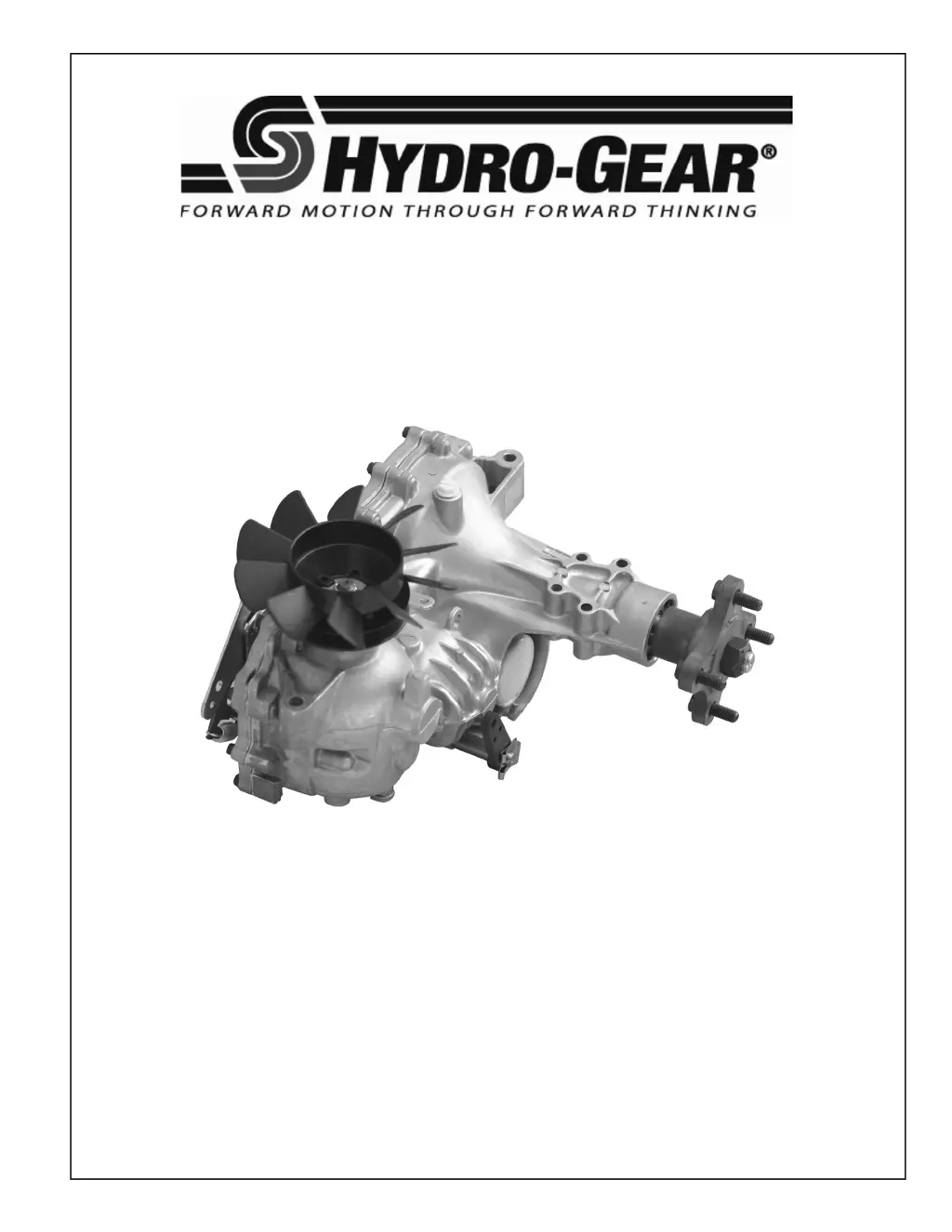

If your Hydro-Gear lawn mower accessories unit has no or low power, it could be due to several reasons. You may need to adjust to the correct setting. Another potential cause is low or contaminated oil; in this case, fill to the proper level or change the oil. Also, the linkage, drive belt or pulley may need repair or replacement.