33

Troubleshooting (Cont’d.)

10

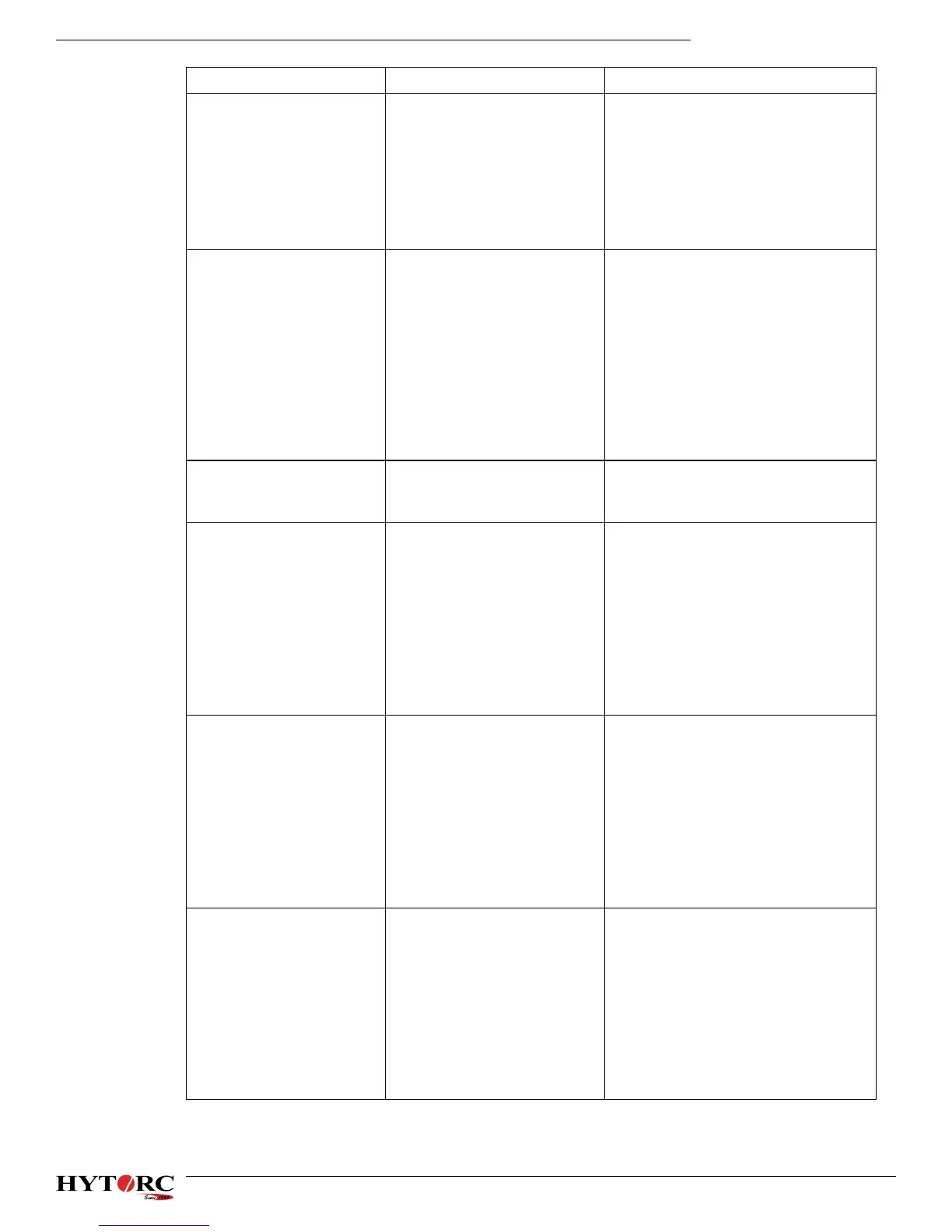

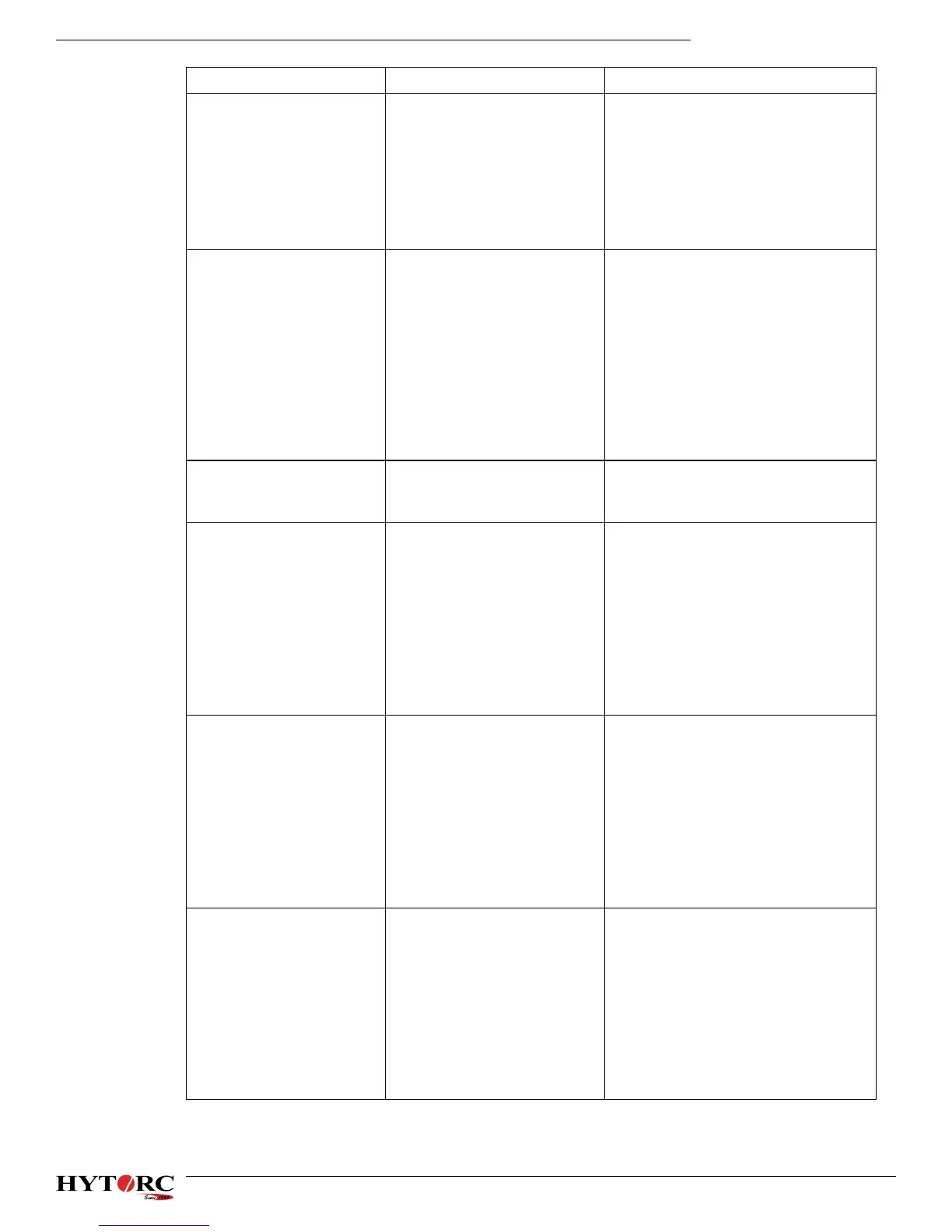

SYMPTOM PROBABLE CAUSE REQUIRED ACTION

Gauge records no pressure 1. Gauge connection is loose

2. Bad gauge

3. Pump will not build pressure

4. Tool seals are blown

1. Tighten coupling.

2. Replace gauge

3. See cylinder pressure will not build pressure-

above

4. Replace defective seals. (Call for service)

Pump will not build pressure 1. Air or electric supply is low

2. Defective relief or regulator valve

3. Low oil or clogged filter

4. Internal leak in oil line from external

relief valve to pump body.

5. Worn sub-plate

1. Check air pressure or voltage.

2. Replace valve. (Call for service)

3. Fill reservoir and clean filter.

4. Open reservoir, inspect oil line while trying to

build pressure - if leaking tighten fittings or replace.

5. See cylinder pressure will not build pressure-

above

Motor sluggish and inefficient

“sounds sick” slow to build pressure

1. Air or electric supply is low

2. Clogged filter

1. Check air pressure or voltage.

2. Clean or replace filter

Pump heats up 1. Improper use

2. Remote control is left in “on” position

when pump is not actively in use.

1. Operator is continuing to hold down Pump

heats up on the advance stroke after the cylinder

has reached end of stroke - this causes a lot of

oil to go through a very small hole in relief-valve

- causing heat build-up. Have operator release

advance stroke after accuracy assurance levers

spring forward.

2. Turn pump off whenever not actually being

used. DO NOT leave pump running when tool

is not in use.

Hose or tool fitting is damaged or

leaks

1. Broken or melted plastic outer

covering

2. Frayed Kevlar or steel strands

3. Oil leaks through fibers

4. Broken fittings

1. If underlying Kevlar or steel is still intact continue

operation. Inspect frequently.

2. Cut hose In half and discard. Replace hose.

3. Cut hose in half and discard. Replace hose.

4. Remove old fitting and replace with STEEL

high pressure fittings only. After changing fittings,

always run test #5 (pg. 34) to insure proper

plumbing.

Electric pump will not run 1. Loose electric connections in control

box.

2. Bad brushes

3. Motor burned up

1. Open control box and visually inspect for loose

threaded or push-on connectors. Reconnect loose

wires. If in doubt check wiring diagram. DANGER·

BOX CONTAINS HIGH VOLTAGE· ALWAYS

UNPLUG PRIOR TO TOUCHING ANYTHING

IN CONTROL BOX.

2. Change brushes. (Call for service)

3. Replace motor or components whichever is

necessary. (Call for service)

(Continued on following page.)

Loading...

Loading...