or gain. All of the risers including the riser stubouts should

be properly covered with insulation. Internally mounted

chilled water piping and valves are located over the drain

pan and need not be insulated.

Any reproong requirements where risers or piping

penetrate oors or walls are the responsibility of the

installer. This work should be done only after all pressure

testing is completed. The reproong method used must

accommodate pipe expansion and contraction and the

piping must be protected from abrasion and chemical attack.

The pipe insulation also must be maintained to prevent

sweating and must be protected from wear or erosion at the

joint between the insulation and the reproong material.

When no risers are ordered for the Mega Modular unit, it is

the responsibility of the installer to make sure that a eld

supplied isolation ball valve is installed between each supply

and return piping connection to the unit. Flare ttings are

factory provided to allow connection between the ball valves

and the hoses.

Variations in oor-to-oor dimensions may require eld work

such as cutting o or extending the risers. This operation is

the responsibility of the installer. The riser joint ller material

must be selected to withstand the total operating pressure

(both static and pumping head) to which the system will be

subjected. Low temperature lead alloy solders such as “50/50”

and “60/40” are normally not suitable.

Chilled water and hot water risers should never be piped

to drain down into the condensate riser. Extensive water

damage can occur due to drain overow. Drain chilled and

hot water risers to a remote location away from the unit such

as sink, room and oor drains.

All installations should be made in compliance with all

governing codes and ordinances. Compliance with all

codes is the responsibility of the installing contractor.

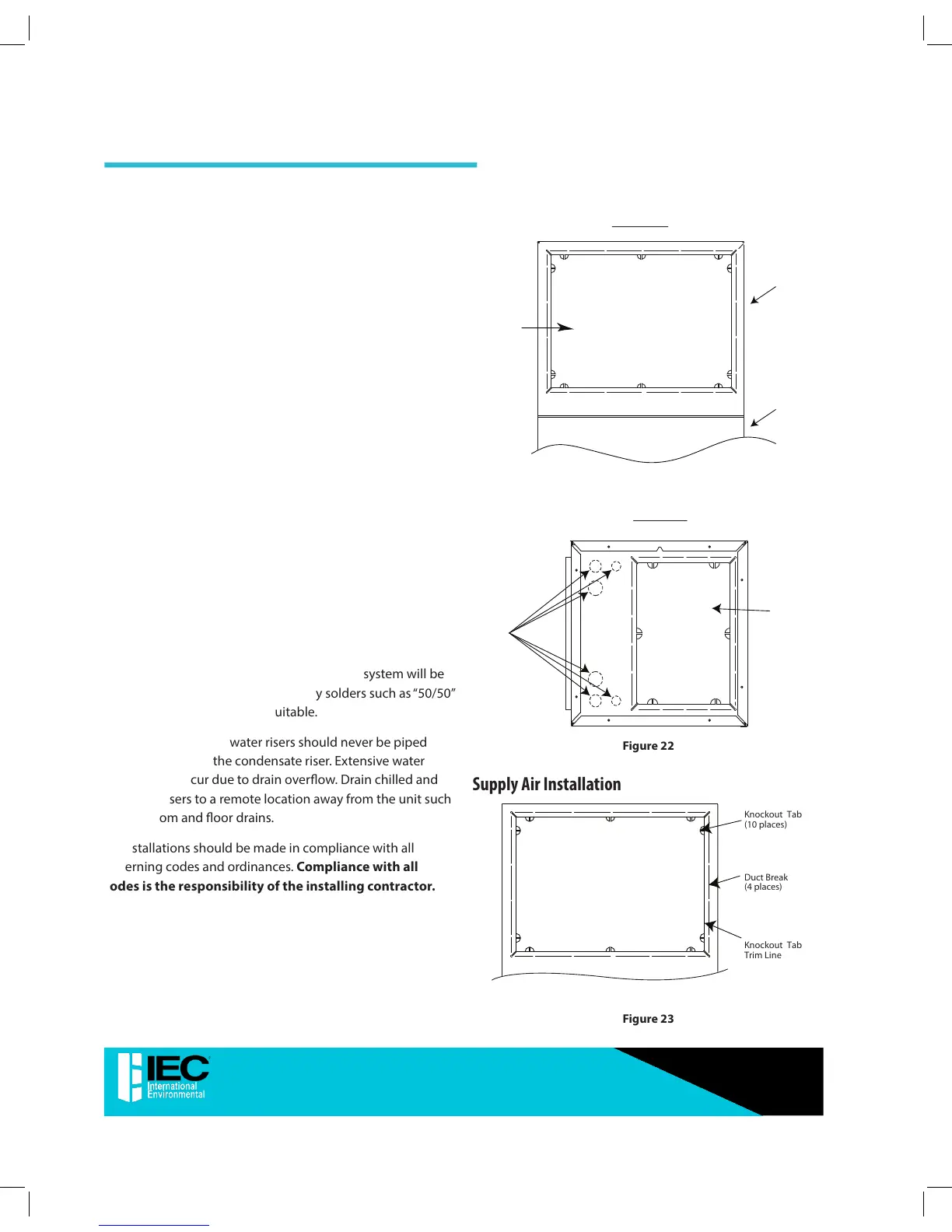

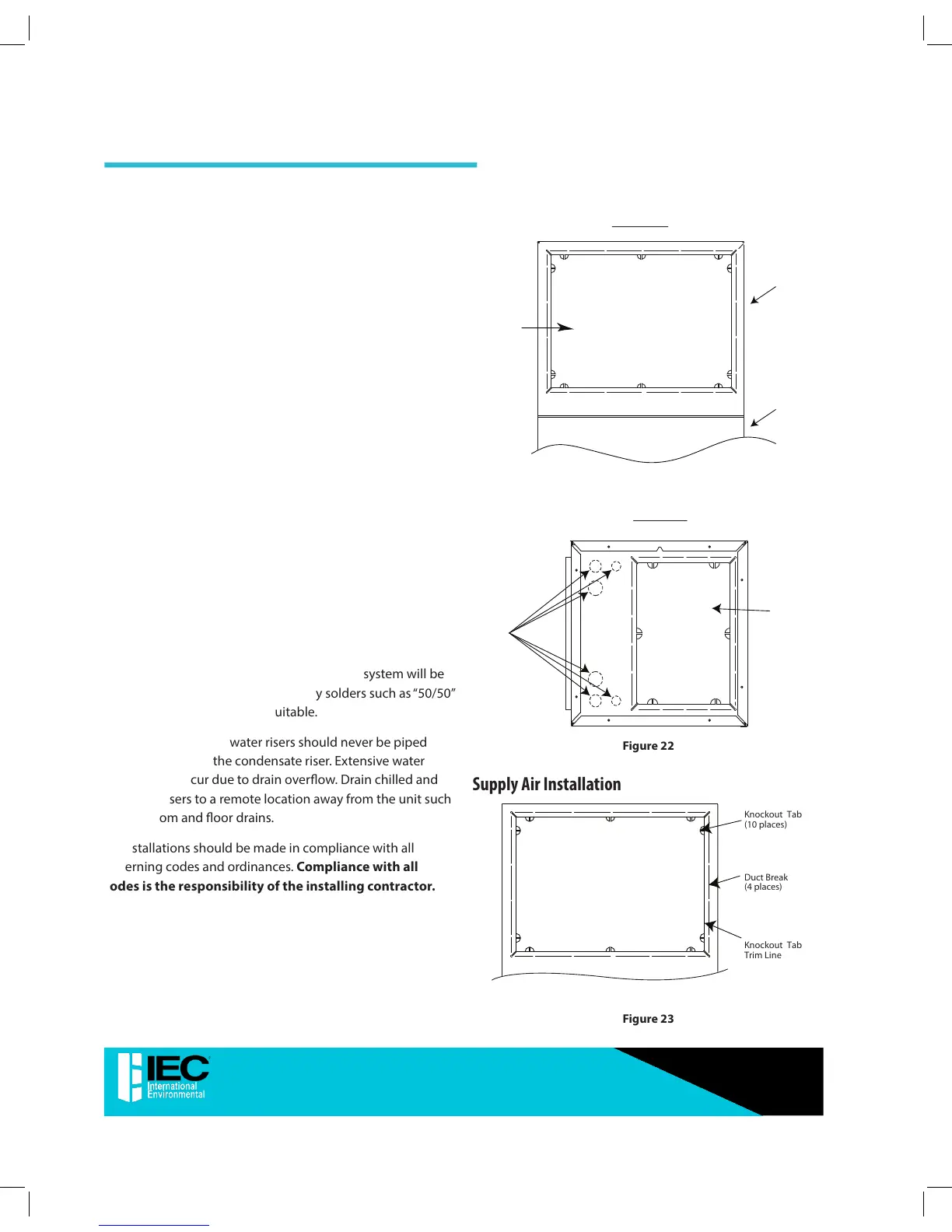

Unit Knockout Locations (Typical)

Loading...

Loading...