Do you have a question about the IMPERIA & MONFERRINA S.p.A. P6 and is the answer not in the manual?

| Brand | IMPERIA & MONFERRINA S.p.A. |

|---|---|

| Model | P6 |

| Category | Pasta Maker |

| Language | English |

Provides general information about the manual's purpose and scope.

Defines key terms and technical vocabulary used in the manual.

Explains the meaning of various symbols used to highlight important information.

Provides contact details for the manufacturer for inquiries and support.

Outlines the safety rules and obligations for operating the machining centre.

Details the manufacturer's limitations of liability for misuse or unauthorized modifications.

Defines rules for authorized operators and safe handling of the machine.

Specifies the terms and conditions of the manufacturer's warranty for the machine.

Offers guidance and recipes for preparing dough for various pasta types.

Instructs the customer on personnel training and general safety rules.

Lists the EU directives and regulations the machine complies with.

Details conformity with essential health and safety requirements of EU directives.

Specifies optimal environmental conditions and ventilation requirements for the machine.

States the machine is not designed for explosive atmospheres and outlines fire safety.

Confirms the machine does not produce hazardous vibrations, warning of mechanical failure.

Provides noise level information and user responsibility for measurement.

Confirms machine conformity with EMC directives and warns about maintenance impact.

Lists and describes the safety devices integrated into the machine.

Explains how to cut out power supplies for maintenance, emphasizing main switch use.

Describes fixed and mobile guards that segregate hazardous zones.

Details the function and operation of the emergency stop button.

Emphasizes the use of PPE and appropriate clothing for safety.

Discusses identified residual risks and necessary precautions.

Covers hazard warning plates, their importance, and prohibition of removal.

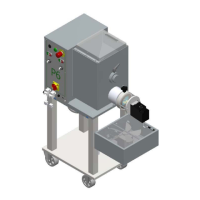

Identifies and illustrates the main components of the pasta machine with a legend.

Presents the key technical data of the machine, including capacity and weight.

Lists and illustrates the standard accessories included with the machine.

Details optional attachments available for purchase to enhance machine functionality.

Provides instructions for safely positioning the machine on a level surface.

Details the steps for installing the machine, including plate and screw fitting.

Guides on connecting the machine to a 380V power supply, including phase checks.

Explains how to connect the machine to a 220V power supply, including phase checks.

Lists packaging materials and provides guidance on their disposal.

Identifies and explains the function of all control buttons and selectors on the panel.

Details the step-by-step process for operating the machine to knead dough.

Provides instructions on how to change the pasta plate to produce different shapes.

Outlines essential safety rules and warnings for performing maintenance operations.

Details specific hazards and precautions related to high voltage and moving parts.

Provides general warnings and best practices for maintenance and repair operations.

Defines the required qualifications and knowledge for maintenance personnel.

Mandates periodic checks and functional tests on all safety devices.

Outlines the procedure for stopping and setting the machine in maintenance mode.

Provides instructions for cleaning the mixing tank and its components.

Highlights components prone to wear and requiring regular checks and replacement.

Lists spare parts not included in standard supply but recommended for maintenance.

Details the parts and quantities for the machine's truck assembly.

Lists the components and quantities for the pastry cutter motor assembly.

Details the parts and quantities for the machine's control panel.

Lists the components and quantities for the electrical switchboard.

Details the components and quantities for the press tank assembly.

Lists the components and quantities related to the machine's motorization.

Presents the electrical wiring diagram for the 380V, 50Hz power supply.

Presents the electrical wiring diagram for the 220V, 50Hz power supply.