18

DAILY 4x4 ‒ GUIDELINES FOR BODYBUILDERS

CHASSIS INTERVENTIONS

2.5 REAR OVERHANG MODIFICATION

– Printed 692.68.999 – 3 Ed. - Base 08-2020

In all cases, the parties performing the work shall be liable thereof.

2.5.2 Authorisation

Rear frame elongation as well as shortening to the smallest value for each model of the series do not require authorisation if per-

formed in compliance with the instructions provided herein.

The standard overhang values in relation to the wheelbases are shown in Table 2.11.

Table 2.11 - Standard overhang and wheelbases

Wheelbase

[mm]

Overhang

minimum - maximum

[mm]

3080 879 - 1794

3480 899 - 2049

3780 963 - 2088

4175 1646 - 2436

Note

If the length of the electrical circuits needs to be adjusted, please refer to Section 5, "Electronic subsystems".

2.5.3 Shortening

The last crossbar must be moved forward when shortening the rear overhang of the frame.

When the rear crossbar is too close to another crossbar, the latter can be eliminated if it plays no role in suspension support.

2.5.4 Lengthening

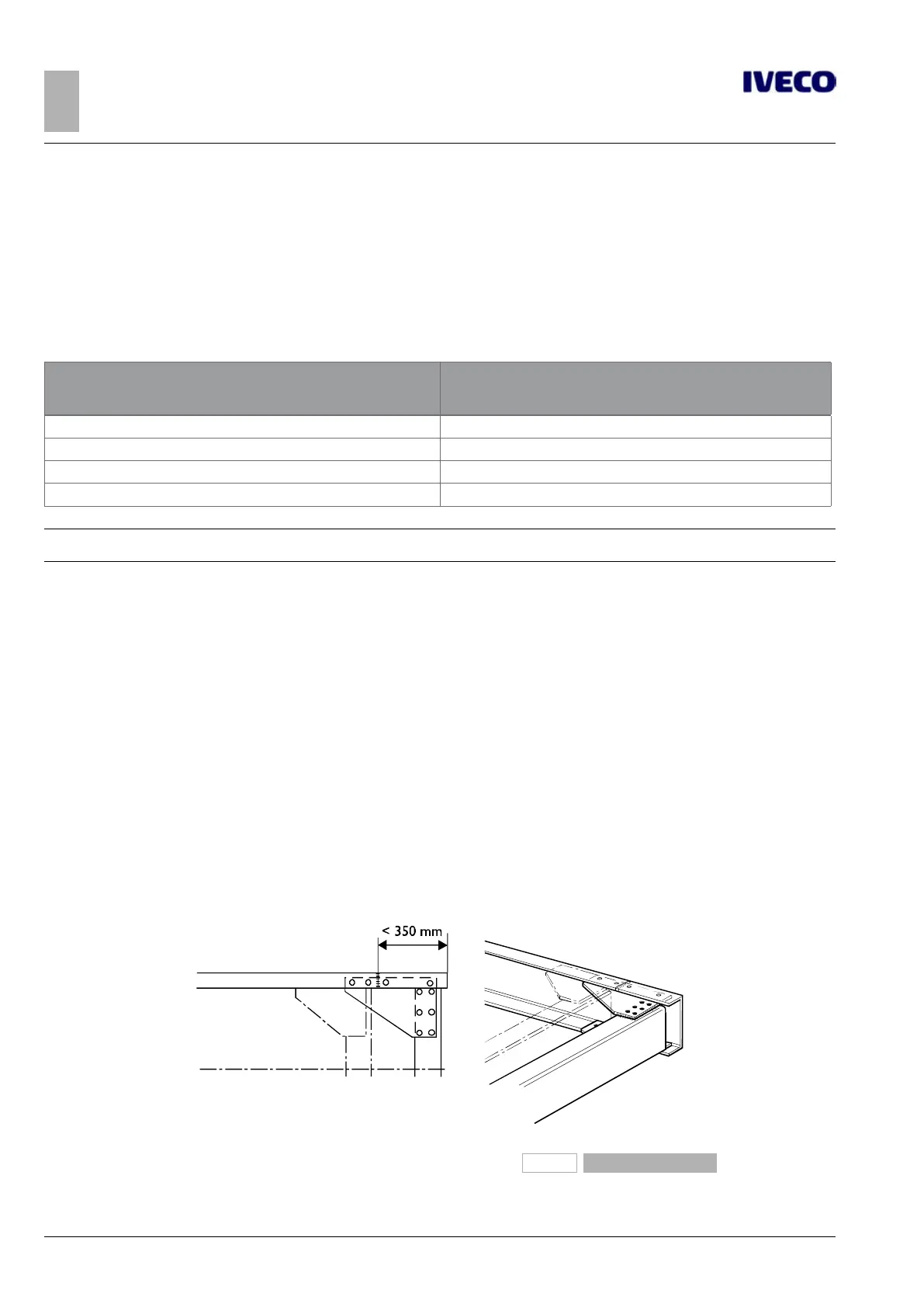

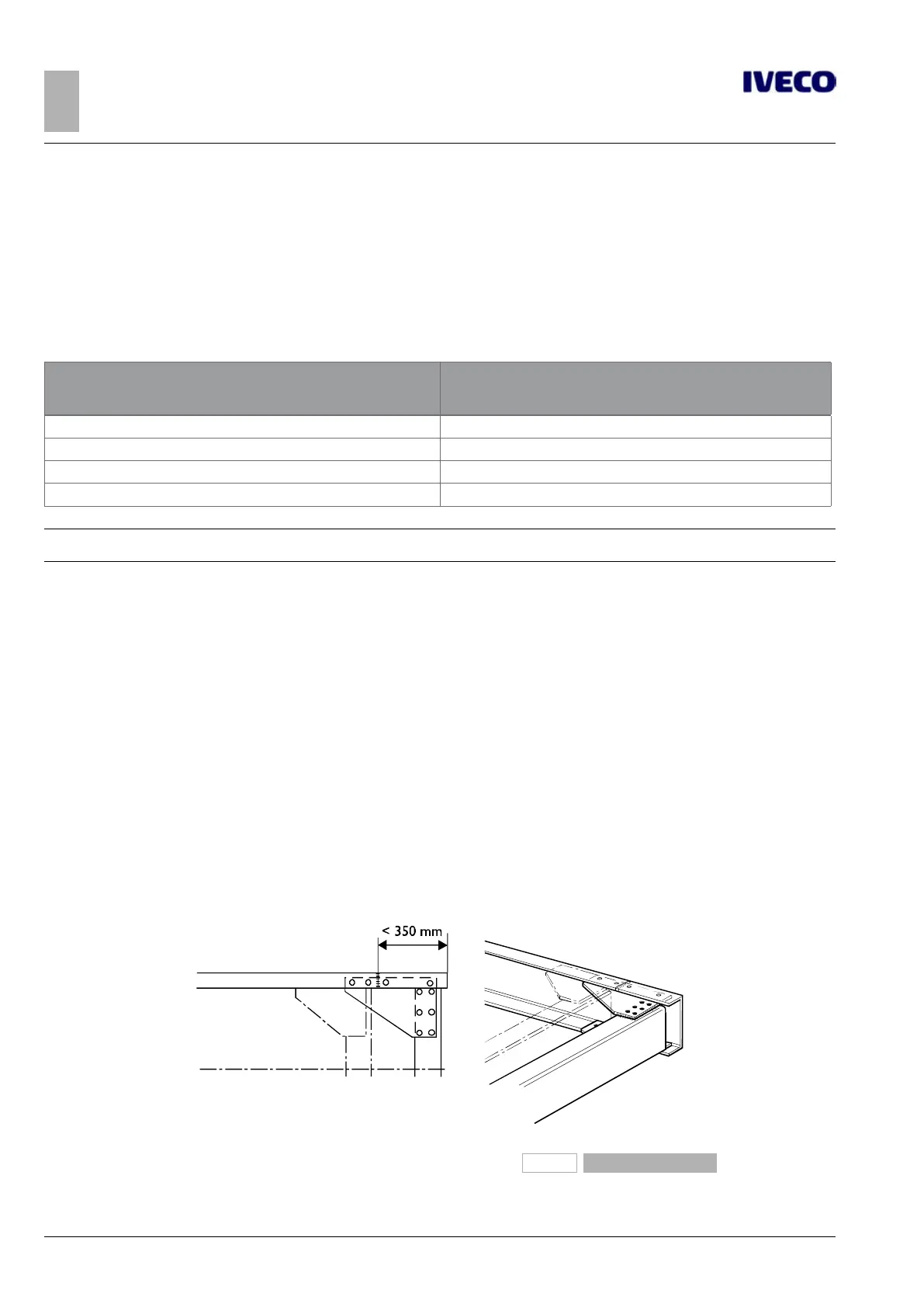

Possible solutions, in relation to the length of the elongation, are shown in Figures 7, 8, and 9.

Cuts can be of straight type. The minimum dimensions of the reinforcements to apply in the area of modification are shown in

Figure 3.

The solution for elongations no greater than 300–350 mm is shown in Figures 7 and 8; in this case, the corner reinforcements,

which also serve as junction between cross member and frame, must have the same width and thickness of the original gusset plate.

The union between the cross member and plate, originally performed using nails, can be done with screws class 8.8 having the next

largest scale diameter and anti-unscrewing nuts.

The solution for elongations greater than 350 mm is shown in Figure 9.

208211

Figure 7

Loading...

Loading...