18z-1, 19c-1, 19c-1 EP

14

15

Please see operator manual for full details.

1

4

7

2

5

8

3

6

9

Insert Isolator Key

Engine Pre Heat

Lower LH Arm Rest

Raise LH Arm Rest

Disarm Immobiliser

Press 2 GO Button

Engage Seat Belt

Start Machine

Operate Machine

Maintenance

Service Points

147 9831/2900-1 147

Service Points

General

The following illustrations identify the service points for the operator to perform the daily and weekly

maintenance tasks.

Engine Compartment

Figure 112.

E

F

B

C

G

D

A

H

A Air filter B Water separator

C Oil filler cap D Coolant expansion bottle

E Battery F Engine oil dipstick

G Battery isolator H Fuel pre filter

Operation

Entering and Leaving the Operator Station

36 9831/2900-1 36

Entering and Leaving the Operator Station

General

For: 18Z-1 ................................................................................................................................. Page 36

For: 16C-1, 19C-1 .................................................................................................................... Page 38

(For: 18Z-1)

WARNING For safety reasons, machines installed with single access canopies from new must not have

the barrier removed. The machine must always be entered/exited with the left hand isolator raised via the

left hand side.

WARNING Do not enter or exit the cab unless the controls isolation lever is in the fully raised position.

CAUTION Entering or leaving the operator station must only be made where steps and handrails are

provided. Always face the machine when entering and leaving. Make sure the step(s), handrails and your

boot soles are clean and dry. Do not jump from the machine. Do not use the machine controls as handholds,

use the handrails.

Entering the Canopy

1. Check that the left control console is raised. When the left control console is in the raised position the

excavator and track controls cannot be operated ( dozer control is still active).

Refer to: Control Lock.

Figure 20.

B

A

A Handle B Left control console

2. Hold the two handrails (one each side of the canopy entrance), use the track to climb to the cab step.

Refer to Figure 21.

Operation

Seat Belt

52 9831/2900-1 52

Seat Belt

General

WARNING Operating the machine without a seat belt can be dangerous. Before starting the engine, make

sure your seat belt is fastened. Check the tightness and condition of the seat belt securing bolts regularly.

WARNING When a seat belt is installed on your machine replace it with a new one if it is damaged, if the

fabric is worn, or if the machine has been in an accident.

Static Seat Belt

Fasten the Seat Belt

WARNING If you do not wear your seat belt you could be thrown about inside the machine, or thrown out of

the machine and crushed. You must wear a seat belt when using the machine. Fasten the seat belt before

starting the engine.

1. Sit correctly in the seat.

2. Push the tongue into the latch. Make sure the seat belt is worn snug and properly located on the body.

Make sure the seat belt is not twisted and that it is over your hips not your stomach.

Figure 34.

B

A

A Tongue B Latch

Adjust

1. Move the toggle the required distance down the strap.

2. To make the strap longer, pull the end as far as it will go.

3. To make the strap shorter, pull the end as far as it will go.

Figure 35.

A Tongue B Toggle

C Strap (pull here to lengthen) D Strap (pull here to shorten)

About the Product

Interior Switches

23 9831/2900-1 23

Interior Switches

Ignition Switch

The ignition key operates the four-position ignition switch. The ignition key can only be inserted or removed

in position 0.

If the engine fails to start, the ignition key must be returned to position 0 before the starter motor is re-engaged.

Do not crank the engine for more than 30s. Allow the starter motor to cool for at least 2min before cranking

the engine again.

Figure 16.

B

A

A Ignition switch B Ignition key

Table 5. Switch Positions for 16C-1 and 18Z1

Position Function

0 Off/Stop the Engine: Turn the ignition key to this position to stop the engine.

Make sure the controls are in neutral and the excavator and dozer are lowered

before you stop the engine.

I On: Turn the ignition key to this position to connect the battery to all of the elec-

trical circuits. The ignition key will return to this position when it is released from

position II or position III.

II Heat position. Turn the ignition key to this position to operate the glow plug or

grid heater for the appropriate time.

III Start: Turn the ignition key to this position to operate the starter motor and turn

the engine. The ignition switch has an inhibitor to stop the ignition switch being

turned ON when the engine is running.

Table 6. Switch Positions for 19C-1

Position Function

0 Off/Stop the Engine: Turn the ignition key to this position to stop the engine.

Make sure the controls are in neutral and the excavator and dozer are lowered

before you stop the engine.

I On: Turn the ignition key to this position to connect the battery to all of the elec-

trical circuits. The ignition key will return to this position when it is released from

position II or position III.

II This position is not used.

III Start: Turn the ignition key to this position to operate the starter motor and turn

the engine. The ignition switch has an inhibitor to stop the ignition switch being

turned ON when the engine is running.

Cab Interior Light

Press either end of the light unit to switch on the cab interior light. Pressing the other end will switch the light off.

Make sure the light is turned off when you intend to leave the machine for a long period of time.

Operation

Working with the Excavator Arm

88 9831/2900-1 88

Digging

General

WARNING Do not use pedals which are not locked in position as foot rests.

Notice: When carrying out deep digging it is advisable to have the super structure swung in line with the

chassis. It is possible that part of the dig end may contact the machine. Take extra care when digging to

avoid damaging the machine.

Notice: Do not excavate on hard or rocky ground with the boom positioned diagonally across the

undercarriage. The resulting rocking motion could cause damage to the track gearbox sprockets and tracks.

Notice: Do not use the side of the excavation to stop the bucket when slewing back into position for the

next dig. Similarly, do not use the side of the bucket to push soil into the excavation. Both these practices

will damage the machine.

It is possible when excavating, to use either full machine slew when discharging a loaded bucket, or if conditions

dictate, swinging the excavator end only to the required dumping area.

1. To start the dig, reach out with the boom and dipper and position the bucket.

2. Slowly crowd the bucket at the same time bring the dipper in. Make sure the bucket stays at the same angle

to the ground while it travels. If necessary, at the same time apply a downward pressure on the boom, to

increase the digging force on the bucket.

Figure 71.

3. When the bucket is full, crowd it fully and at the same time move the dipper out a small distance. This will

keep soil from building up under the machine.

Figure 72.

4. Slew the machine or swing the bucket to the dump area.

Insert isolator key (A) and

turn in a clockwise direction.

Turn ignition to position 1 (A)

to pre-heat engine before start.

Wait until pre-heat symbol (B)

on instrument panel goes off.

Lower the LH arm rest to

activate the hydraulics.

Note: If 2 GO enabled go to step 8,

if not go to step 9

If enabled press 2 GO button

(A) to activate hydraulics.

Instrument panel will illuminate

(B) when active.

All controls are now active

and the machine is now ready

to use.

If fitted disarm by entering PIN

code using one of the below

methods.

From ignition position 1 turn

ignition to position 3 (A) to start

the machine.

Ensure the hydraulic isolation

lever (left hand arm rest) is in

the raised position.

Engage seat belt (A) into latch

(B) before starting machine.

A Handle B LH arm rest

A Handle

B LH arm rest

Operation

Starting the Engine

59 9831/2900-1 59

If the PIN code is incorrectly entered five times the immobiliser will lock for 15min. In this event it is

recommended that you contact the machine owner for confirmation of the PIN code.

The PIN code will have to be entered every time that the ignition is switched off for longer than two minutes.

To Disarm the Immobiliser to Allow the Machine to be Used

1. Put the ignition key in the ignition switch. Turn the ignition key to position 1.

2. Enter your four digit PIN code using the keypad.

3. Push the 'ENT' button. The LED will come on for three seconds if the PIN code is correct and the machine

can be started.

4. If an incorrect PIN code is entered the unit will lock. The LED will flash twice quickly, pause and then flash

twice again and will continue this pattern until the ignition key is turned to the off position. In this event

return to step 1 to try again.

4.1. After five failed tries the system will lock.

Duration: 15min

Figure 40.

A LED

To Arm the Immobiliser

1. Stop the engine. Remove the ignition key.

2. The immobiliser arms automatically after two minutes. The green LED flashes for 60 seconds, then goes off.

3. If you restart the engine within two minutes, the system disarms automatically.

To Add a New or Additional PIN Code

Before you try to add a new or additional PIN code, make sure that the machine is ready to start and that you

have your six digit master code and your new four digit PIN code available.

If you are unsure of the master code or your new PIN code, then do not start this procedure.

The keypad immobiliser can be programmed to accept up to 14 different four digit PIN codes, any of which

will let the machine be started.

1. Put the ignition key in the ignition switch. Turn the ignition key to position 1

2. Enter your six digit master code using the keypad. Push the 'ENT' button.

3. The LED will flash three times to indicate the acceptance of the master code.

4. Within 59 seconds of the three flashes, push the 'MD' button.

A

A

A B

B

Start Up Sequence

A

About the Product

Interior Switches

23 9831/2900-1 23

Interior Switches

Ignition Switch

The ignition key operates the four-position ignition switch. The ignition key can only be inserted or removed

in position 0.

If the engine fails to start, the ignition key must be returned to position 0 before the starter motor is re-engaged.

Do not crank the engine for more than 30s. Allow the starter motor to cool for at least 2min before cranking

the engine again.

Figure 16.

B

A

A Ignition switch B Ignition key

Table 5. Switch Positions for 16C-1 and 18Z1

Position Function

0 Off/Stop the Engine: Turn the ignition key to this position to stop the engine.

Make sure the controls are in neutral and the excavator and dozer are lowered

before you stop the engine.

I On: Turn the ignition key to this position to connect the battery to all of the elec-

trical circuits. The ignition key will return to this position when it is released from

position II or position III.

II Heat position. Turn the ignition key to this position to operate the glow plug or

grid heater for the appropriate time.

III Start: Turn the ignition key to this position to operate the starter motor and turn

the engine. The ignition switch has an inhibitor to stop the ignition switch being

turned ON when the engine is running.

Table 6. Switch Positions for 19C-1

Position Function

0 Off/Stop the Engine: Turn the ignition key to this position to stop the engine.

Make sure the controls are in neutral and the excavator and dozer are lowered

before you stop the engine.

I On: Turn the ignition key to this position to connect the battery to all of the elec-

trical circuits. The ignition key will return to this position when it is released from

position II or position III.

II This position is not used.

III Start: Turn the ignition key to this position to operate the starter motor and turn

the engine. The ignition switch has an inhibitor to stop the ignition switch being

turned ON when the engine is running.

Cab Interior Light

Press either end of the light unit to switch on the cab interior light. Pressing the other end will switch the light off.

Make sure the light is turned off when you intend to leave the machine for a long period of time.

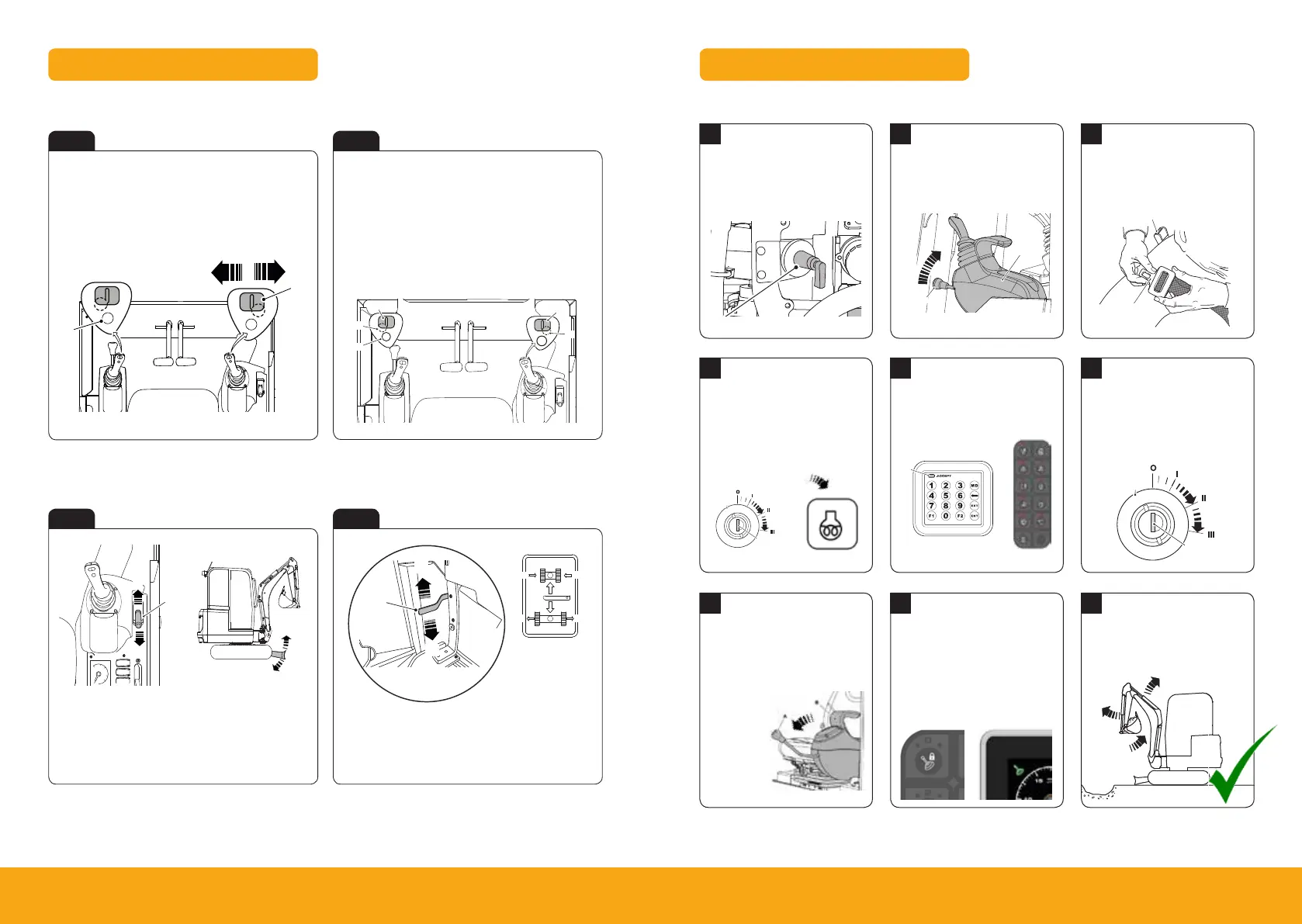

Joystick & Dozer Lever

Swing Controls – 19c-1 EP Auxiliary Controls – 19c-1 EP

Dozer Lever Retracting Undercarriage Lever

Fig 19 Fig 20

Fig 21 Fig 22

Operation

Operating Levers/Pedals

80 9831/2900-1 80

Swing

Figure 62. 16C-1 and 18Z-1

A Swing left B Swing right

To swing the boom to your left, push the swing pedal to the left side. Release the pedal when the excavator

end has reached the required position.

To swing the boom to your right, push the swing pedal to the right side. Release the pedal when the excavator

end has reached the required position.

Figure 63. 19C-1

C

D

A Swing left B Swing right

C Thumb wheel D Change over button

Press the change over button on the left joystick to select swing mode. An icon is displayed on the instrument

panel.

Press the change over button on the left joystick to select swing mode. An icon is displayed on the instrument

panel. To swing the boom to your left move the thumb wheel on the right joystick to the left. Release the thumb

wheel when the excavator end has reached the desired position.

To swing the boom to your right move the thumb wheel on the right joystick to the right. Release the thumb

wheel when the excavator end has reached the desired position.

Operation

Operating Levers/Pedals

83 9831/2900-1 83

The electro-proportional switch on the right joystick controls swing or high flow attachments (press the change

over button on the left joystick to select auxiliary mode). An icon is displayed on the instrument panel. The

finger button on the right joystick can be used for hammer (constant full flow).

The electro-proportional switch on the left joystick controls low flow attachments.

Figure 67. 19C-1

E

A

B

D

C

A Tilt/grab changeover for tilt-rotator B Boom swing/aux changeover

C Left electro-proportional switch for aux 2 (low

flow)

D Right finger button - hammer

E Right electro-proportional switch for aux 1 (high

flow) or boom swing

Operation

Operating Levers/Pedals

81 9831/2900-1 81

Dozer Blade Controls

Notice: Before operating the dozer blade, make sure that large rocks or other objects will not jam the dozer

mechanism.

The dozer is operated by a single control lever on the right side of the cab. Refer to: Operator Station.

The lever is spring loaded to the central position. In this position the dozer will not move.

To raise the dozer pull the lever backwards. At the required position release the lever.

To lower the dozer push the lever forward until an increased resistance is felt and the blade moves. At the

required position release the lever. Refer to Figure 64.

Figure 64.

A

B

A

B

C

A Lower the dozer B Raise the dozer

C Control lever

Extending Undercarriage Controls

To extend or retract the undercarriage (option):

1. Stop the machine on level ground.

2. Make sure that all persons are away from the machine and the surrounding area.

3. Operate the dozer control lever to lower the dozer blade and lift the tracks just off the ground.

Refer to: Dozer Blade Controls.

4. Operate the excavator controls to slew the machine to specified degrees.

Angle: 180°

5. Operate the excavator controls to lower the excavator arm and lift the rear tracks just off the ground. Refer

to Figure 65.

6. Operate the track extension control lever to move the undercarriage to the required position. Refer to Figure

65.

6.1. Move the lever upward to extend the undercarriage. Both tracks will extend together.

6.2. Move the lever downward to retract the undercarriage. Both tracks will retract together.

Operation

Operating Levers/Pedals

82 9831/2900-1 82

Figure 65.

B

B

C C

A Track extension lever B Upward- retract

C Downward- extend

Auxiliary Circuit Controls

WARNING Before operating the auxiliary control system make sure that you are aware of all safety notices

that apply to the attachment you are using. Also make sure you have installed the attachment correctly and

have read its operator's manual.

Notice: The auxiliary hydraulic circuit a single acting system as standard with optional double acting

system available. If applicable make sure that the single/double acting control is correctly configured for

your attachment before operating it otherwise machine damage could occur.

Push the auxiliary pedal to the left or right depending on the attachment installed and the function required. In

single acting mode, oil flow only in one direction. So pressing the pedal to left will lead to feed line and pressing

the pedal to right will lead to the return line while in double acting mode pushing the pedal to left or right lead

to feed line or return line. Refer to the operator manual supplied with the attachment.

Figure 66. 16C-1 and 18Z-1

A Auxiliary pedal

Electro-proportional Controls

Attachments are operated using the joysticks.

Use the auxiliary switch on the console to select either single acting or double acting high flow/low flow

operation. Check the instrument panel.

A Swing left

B Swing right

C Swing thumb wheel control

D Change over button

A Tilt/grab changeover for tilt-rotator

B Boom swing/Aux change over button

C Thumb wheel control – Aux 2 (Low flow)

D Continuous flow button – Hammer circuit

E Thumb wheel control – Aux 1 (High flow)

Note: A & D located underside of joystick

A Lower the dozer

B Raise the dozer

C Control lever

A Track Extension Lever

B Upward - Retract

C Downward - Extend

Operation

Operating Levers/Pedals

82 9831/2900-1 82

Figure 65.

A Track extension lever B Upward- retract

C Downward- extend

Auxiliary Circuit Controls

WARNING Before operating the auxiliary control system make sure that you are aware of all safety notices

that apply to the attachment you are using. Also make sure you have installed the attachment correctly and

have read its operator's manual.

Notice: The auxiliary hydraulic circuit a single acting system as standard with optional double acting

system available. If applicable make sure that the single/double acting control is correctly configured for

your attachment before operating it otherwise machine damage could occur.

Push the auxiliary pedal to the left or right depending on the attachment installed and the function required. In

single acting mode, oil flow only in one direction. So pressing the pedal to left will lead to feed line and pressing

the pedal to right will lead to the return line while in double acting mode pushing the pedal to left or right lead

to feed line or return line. Refer to the operator manual supplied with the attachment.

Figure 66. 16C-1 and 18Z-1

A Auxiliary pedal

Electro-proportional Controls

Attachments are operated using the joysticks.

Use the auxiliary switch on the console to select either single acting or double acting high flow/low flow

operation. Check the instrument panel.

Loading...

Loading...