Figure 6

Fig

ure 5

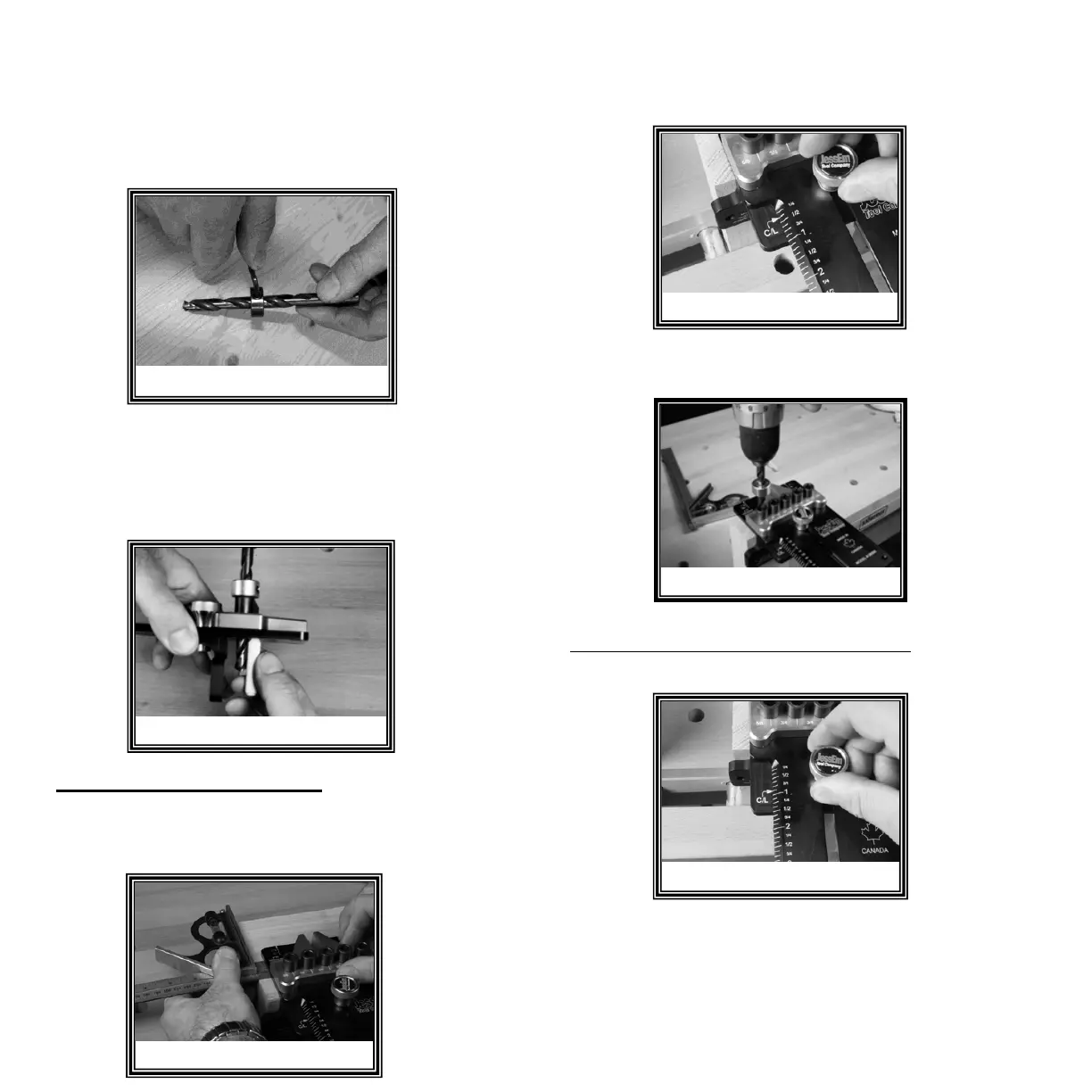

Figure 1

Setting the Drill Bit Depth Collar:

Usi

ng the

matching

stop collar for the drill bit you are using, screw

the ¼”-20 set screw into the stop collar. Now slide the

stop coll

ar

over the drill bit and with the

1/8” hex key

snug

the set

screw to

keep

the colla

r

in position. (See

Figure # 1)

** Note: Locate the set screw on the largest portion of the drill bit

not in one of the chip removal

flutes. (See

Figure # 1)

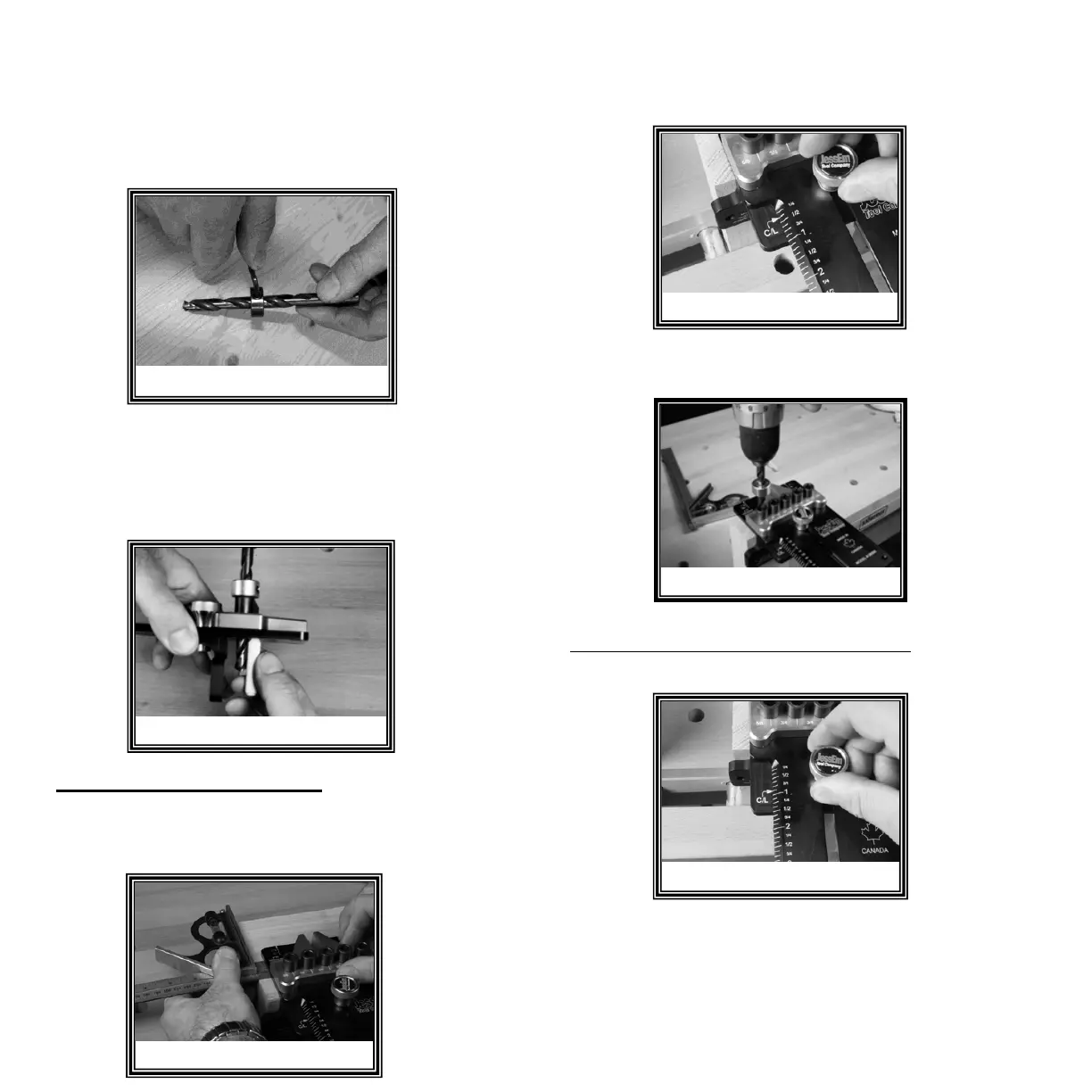

Figure 2

Figure 3

The first joint we are going to drill has 3 rows of dowels. We are

spacing our jig ½” from the edge. Clamp the jig to your board in

this position. (See Figure #3)

Figure 4

We want three (3) holes in this first row. One (1) in the center and

one (1) in

each

outside hole. (See Figure # 5)

With the first row drilled, adjust the jig to the 7/8” position.

Note: Do not unclamp the Jig from your board. (See Figure

#6)

MULTIPLE ROW DOWEL JOINT

Insert the drill bit into the corresponding drill bushing and measure

the amount the drill bit protrudes (See Figure # 2). The drill bit

should be deep enough to accomodate half the dowel you are

using. For thinner stock, ensure the dowel pin does not break

through your material and compensate by

drilling deeper on the

corresponding piece.

We have predetermined that we want the first row of dowels

spaced 3/8" of an inch in from the edge. Loosen the adjustment

knob and adjust the jig to the 3/8" position. (See Figure # 4)

5

Loading...

Loading...