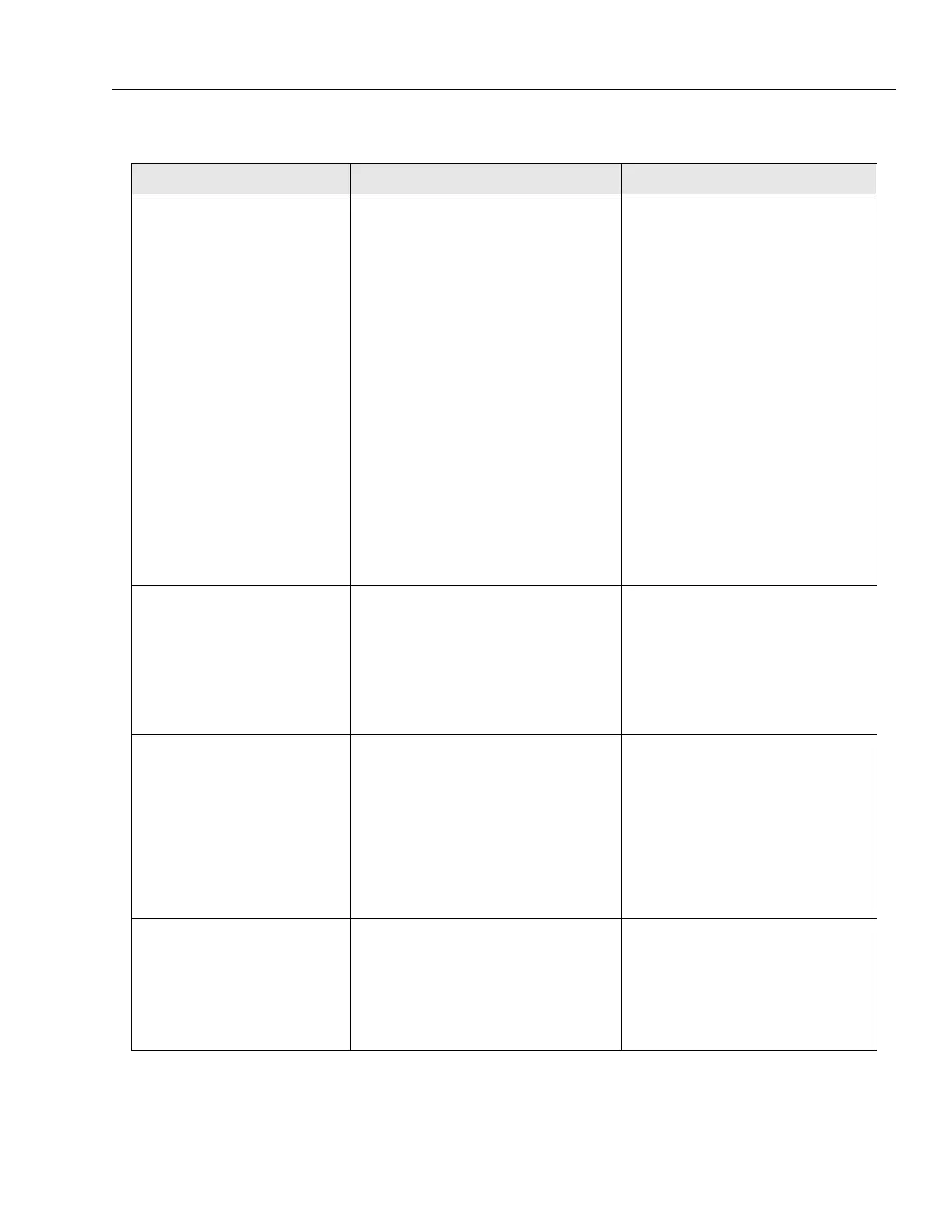

SECTION 1 - JLG SMART SYSTEM ™ ANALYZER KIT INSTRUCTIONS (1600258 CONTROLLER).

3120442 – JLG Sizzor – 1-13

All Machine Functions Do Not Operate.

(cont.) Line contactor or other driver short-circuit or

tripped. (flash code 3-3)

POINT A SHORT CIRCUIT. (FLASH CODE 9-6)

Motor lead connections loose.

Faulty controller.

POINT A OPEN CIRCUIT. (FLASH CODE 9-7)

Faulty controller.

Stalled motor.

Faulty motor.

Disconnect valve harness at J1. Using an ohm

meter, measure resistance between B - and

each pin of the connector, except pin 10. Each

reading should be 1 - 12 megaohms. If any read-

ing is less, replace controller.

Check motor lead connections. Tighten connec-

tions as necessary.

Replace controller.

Replace controller.

Determine cause. Repair or replace motor as

necessary.

Replace motor.

No drive function when platform fully low-

ered. Lift function okay.

CUTOUT INPUT. (FLASH CODE 2-5)

Malfunctioning limit switch. Use analyzer to verify limit switch inputs.Drive

cutout and Elevation cutout should be HI. Adjust

or repair malfunctioning limit switch.

No drive function when platform ele-

vated. Lift function okay.

CUTOUT INPUT. (FLASH CODE 2-5)

Malfunctioning limit switch

Platform above drive cutout height.

Use analyzer to verify limit switch inputs.Pothole

should be HI. Adjust or repair malfunctioning

limit switch.

Lower platform below drive cutout height.

Machine cannot lift down. Lift up function

okay.

CUTOUT INPUT. (FLASH CODE 2-5)

Deck extension extended. Use analyzer to verify limit switch inputs.Exten-

sion limit should be HI.Retract deck extension.

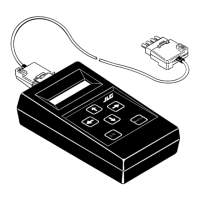

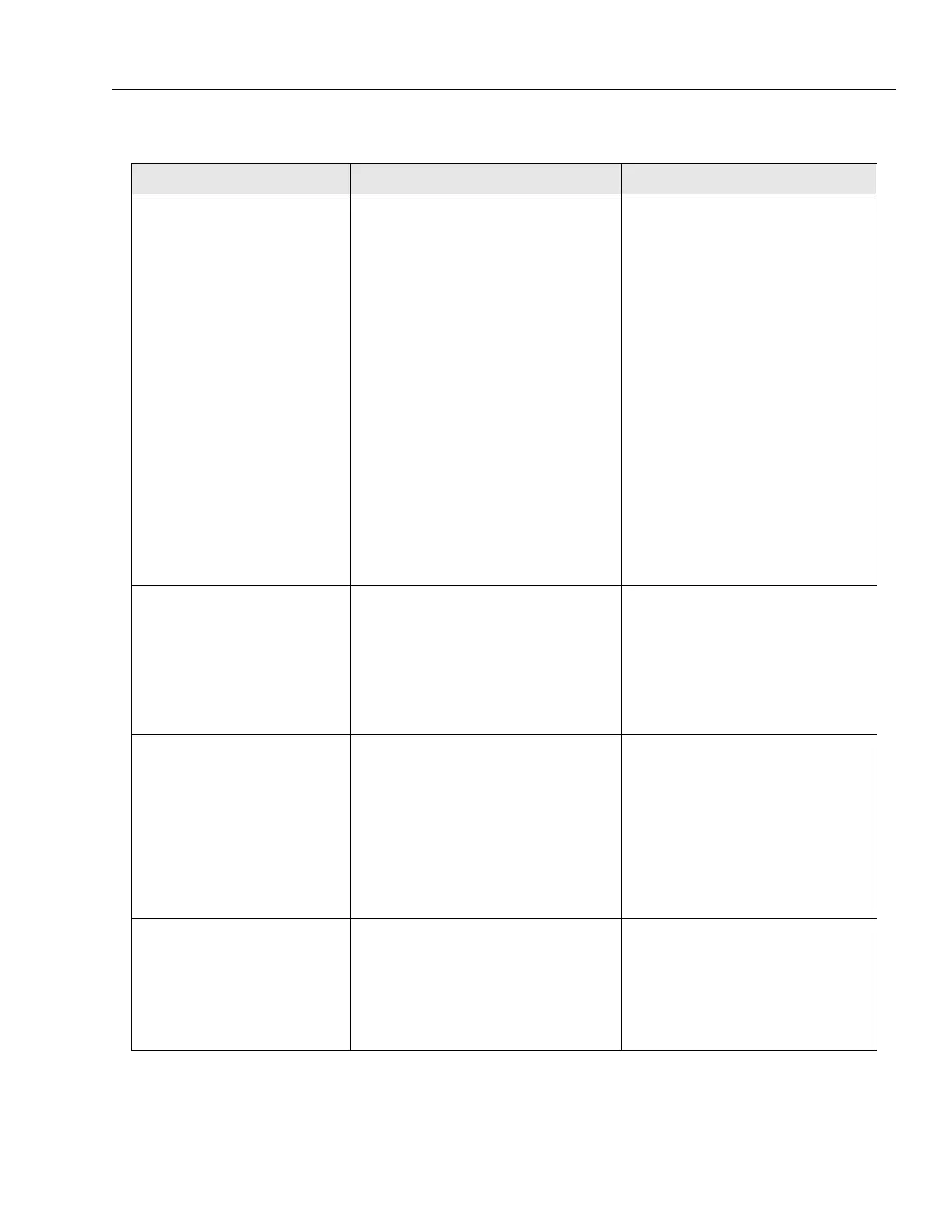

Table 1-6. JLG SMART System™ Troubleshooting

TROUBLE PROBABLE CAUSE REMEDY

Loading...

Loading...