2 FS80-C Flow Switch Installation Instruction

Make all wiring connections using copper conductors only.

Use the terminal screw furnished. Substitution of other screws will void the

warranty and agency approvals.

Adjustments

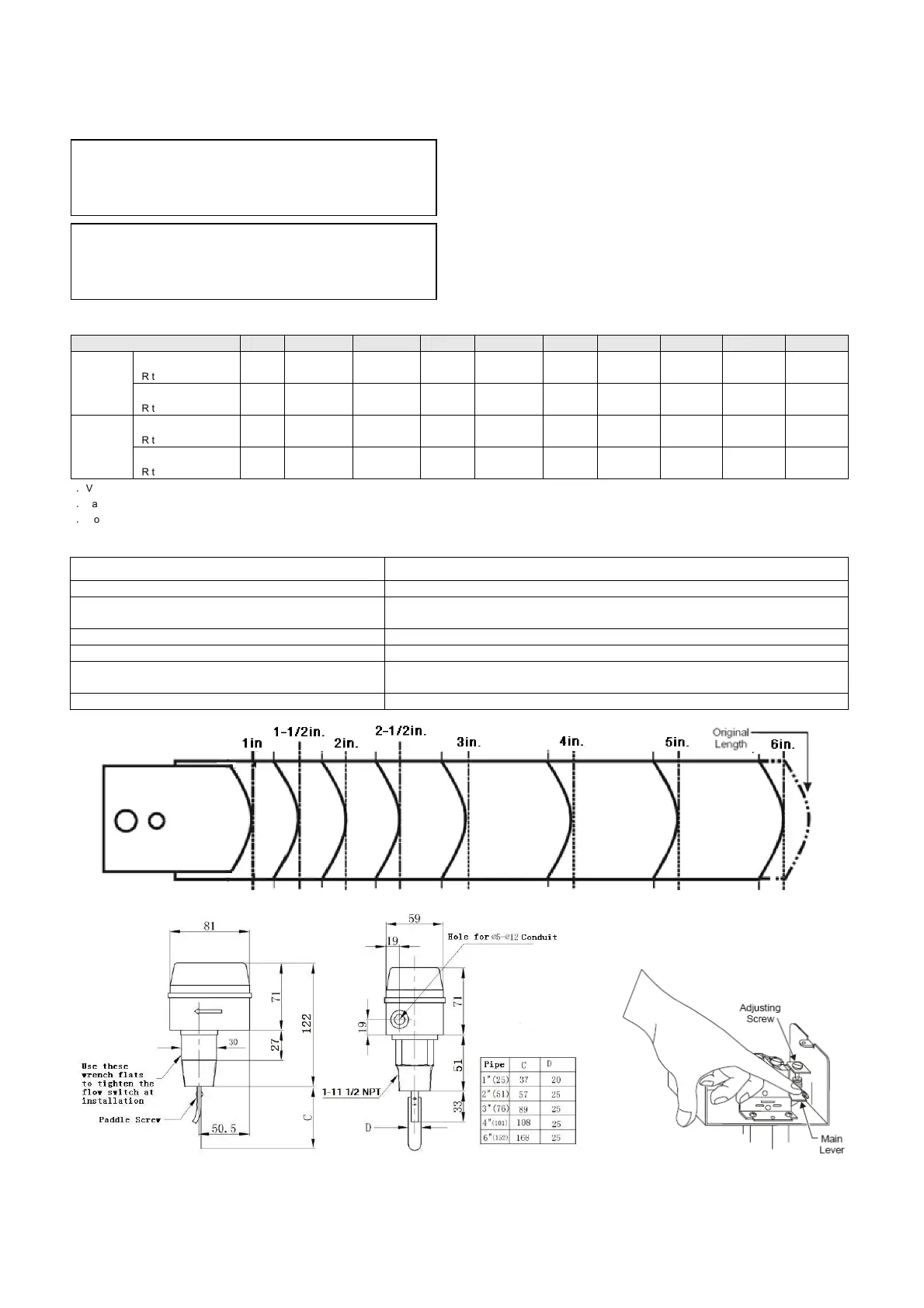

To adjust the setting of the flow switch:

1. Remove the FS80-C cover.

2. For higher flow rates, turn the adjusting screw clockwise. To lower the flow

rates after it has been raised from the factory setting, turn the adjusting

screw counterclockwise. See Figure 1.

3. Check to see that the flow switch is not set lower than factory setting by

depressing the main lever numerous times. If the lever fails to “click” upon

return at any time, turn the adjusting screw clockwise until the lever clicks

upon return every time. See Figure 7.

Checkout Procedure

The circuit between the red and blue leads (terminals) will be closed when

sufficient liquid flows through the pipe to trip the flow switch.

Before leaving the installation, observe at least three complete operating

cycles to be sure that the Flow Switch and the system to which it is connected are

functioning correctly.

Table 1 Typical Flow Rate- m

3

/h Required to Actuate the Switch

a

.

Values for 2 in. paddle trimmed to fit pipe.

b

.

Values for 3 in. paddle trimmed to fit pipe.

c

.

Flow rates for these sizes are calculated installed 1 in., 2 in., 3 in. paddle. Bracket valves are for a switch with a 6 in. paddle, for 4 in. and 5 in. line pipe, the 6 in. paddle is

trimmed to a 4 in. and 5 in. length. For 8 in. line pipe, values are for install 1 in., 2 in., 3 in. and 6 in. paddle.

Table 2 Troubleshooting

Symptom/Problem Solution

Liquid from the tank is leaking into enclosure due to bellows failure.

Replace unit.

Switch will not activate due to debris caught within the switch

mechanism

Clear any debris within the switch mechanism. Test the operation of switch several times for proper

operation

Control switch action is reversed Ensure connections follow wiring diagrams

Control does not switch Check connections

Control will switch on flow but won’t return when there is no flow

On vertical pipe, ensure that direction of flow is up. The arrow on switch must point in direction of

flow (up).

Control does not switch on flow increase Check for cracked/broken paddle. Replace if necessary

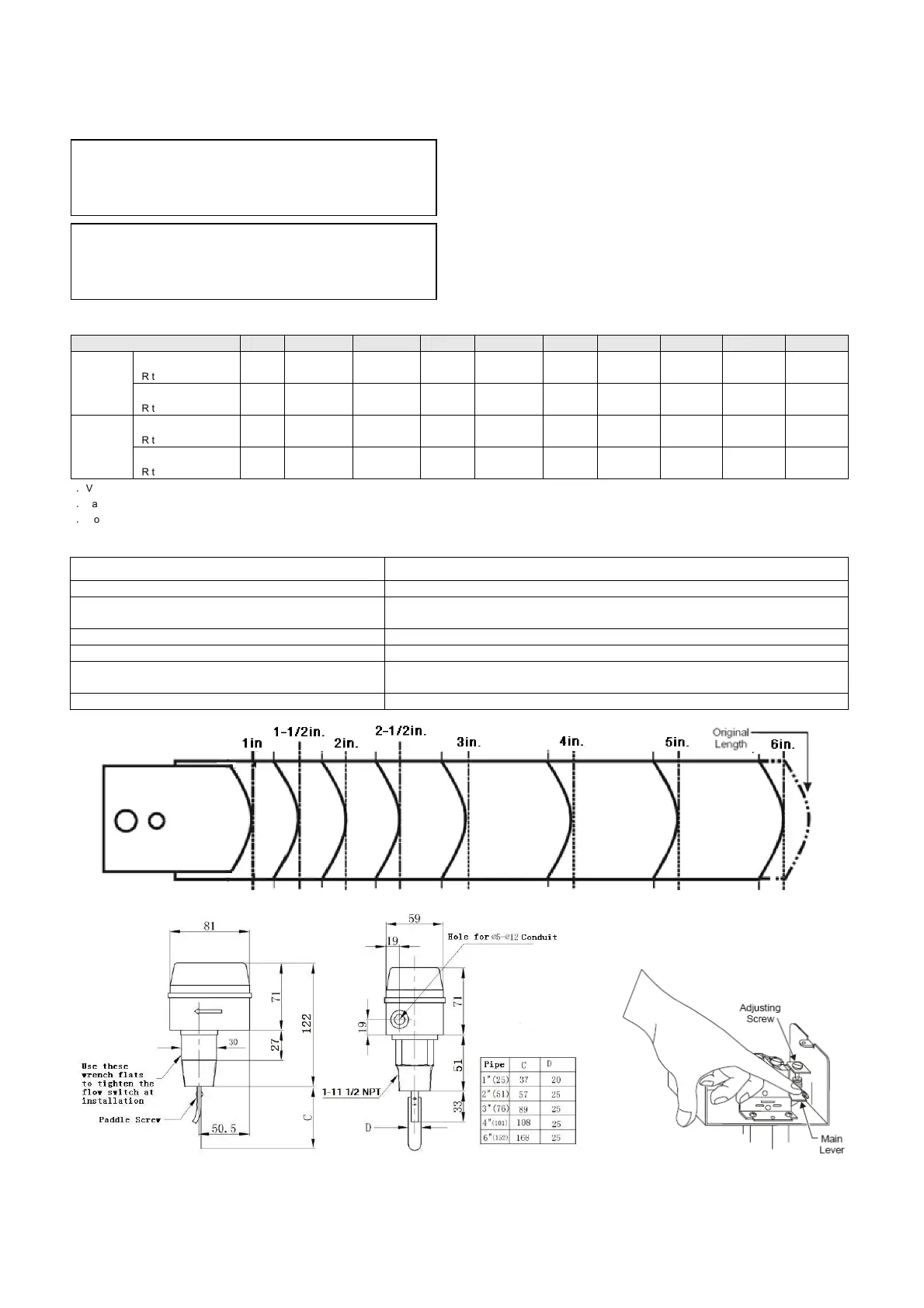

Figure 5 Trimming Template for the Extra Paddle

Figure 6 Dimensions Figure 7 Minimum Adjustment

Pipe Size(in.) 1 1-1/4

a

1-1/2

a

2 2-1/2

b

3 4

c

5

c

6

c

8

c

Flow Increase

R to B Closes

0.95 1.32 1.70 3.11 4.09 6.24

14.8

(8.4)

28.4

(12.9)

43.2

(16.8)

85.2

(46.6)

Min.

Adj.

Flow Decrease

R to Y Closes

0.57 0.84 1.14 2.16 2.84 4.32

11.4

(6.1)

22.9

(9.3)

35.9

(12.3)

72.7

(38.6)

Flow Increase

R to B Closes

2.0 3.02 4.36 6.59 7.84 12.0

29.1

(18.4)

55.6

(26.8)

85.2

(32.7)

173

(94.3)

Max.

Adj.

Flow Decrease

R to Y Closes

1.93 2.84 4.09 6.13 7.3 11.4

27.7

(17.3)

53.4

(25.2)

81.8

(30.7)

166

(90.8)

CAUTION: Equipment damage hazard

The paint sealed setpoint shall not be adjusted randomly. Any attempt

to adjust may result in failure in control and adjustment, and also it’s

out of scope of warranty.

CAUTION: Improper operation hazard

The switch is factory set at approximately the minimum flow rate (see

table 1 Typical Flow Rate). Do not set lower than the factory setting as

this may result in the switch failing to return to a “no flow” position.

Loading...

Loading...