– 31 –

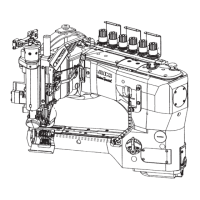

1. Installation and pressure adjustment of presser and presser yoke

(1) Raise the presser shaft , mount the presser yoke on the presser

shaft , and tighten the setscrew .

(2) Confirm whether the presser shaft smoothly moves up and down,

being free from rattling on the right and left.

If there is rattling on the right and left, loosen four setscrews to

set up the presser shaft guide to eliminate right and left rattling

by means of the right/left holding guide plate . Make adjustments

to permit the presser shaft to perform light movement up and down.

Since then, tighten the setscrew .

(3) Install the pressure adjusting leaf spring set and turn the pressure

adjusting nut until pressure of the presser is duly adjusted.

oTurning the pressure adjusting nut clockwise causes the pressure

to increase.

0Turning the pressure adjusting nut counterclockwise causes the

pressure to decrease.

(4) In order to make the presser rise by 3.2mm faster than the upper

feed roller, loosen the setscrew of the presser shaft guide

and move the presser shaft guide up and down until a clearance

of 0.8mm is secured between the lower hole face of the lever link

and the bottom face of the lever link hanger setscrew . (Lower

dead point of the needle bar)

(Caution) When the above-mentioned adjustments are made, the

connecting positions shall be secured for the lifter lever

with slide hole and the lifter lever by moving the

lifter lever with slide hole in the right direction. When

proper positioning has been secured, tighten the

setscrew .

(5) To secure the standard amount of rise of 6.5mm for the presser ,

loosen the setscrew and move the stop collar up and down

until a clearance of 6.5mm is secured between the lower face "C" of

the mounting position of the presser shaft guide bush and the

upper face "D" of the stop collar . Since then, tighten the setscrew

.

(Caution) At the same time, check the mounting position of the

needle thread rocking thread take-up bar connecting

base .

At the lower dead point of the needle bar, a clearance of

1.6mm shall be secured between the bottom face A of

the needle thread rocking thread take-up bar connecting

base and the upper face B of the cut section of the

front cover .

2. Removal and installation of presser only

(1) To replace presser only, loosen the right and left setscrews

and change the presser .

Then, tighten the right and left setscrews .

o If the amount of presser rise is too

excessive than required, the

presser will touch the needle

clamp, thus causing needle

breakage or stitch skipping.

o If pressure of the presser is too

insufficient or excessive than

required, the material cloth will

advance awkwardly.

Adjustment Procedures Results of Improper Adjustment

Loading...

Loading...