– 33 –

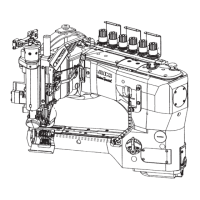

1. Installation of upper feed roller

(1) Raise the upper feed roller pressing shaft and insert the upper

feed roller pressing shaft in the frame shaft hole of the upper

feed roller frame set . Then, tighten the setscrew .

Simultaneously at that time, insert the lever connecting section

in between the roller connecting section to join it.

(2) Install the roller pressure adjusting screw .

(3) Confirm that a standard clearance (Clearance gauge: 0.08mm to

0.13mm) is secured between the upper feed roller and the upper

face of the throat plate .

(4) Confirm that there is proper pressure at the upper feed roller ,

enough to feed the material cloth.

c Pressure adjustment

oTurning the roller pressure adjusting screw clockwise causes the

pressure to increase.

oTurning the roller pressure adjusting screw counterclockwise

causes the pressure to decrease.

(Caution) Confirm that the upper feed roller pressing shaft can

be raised by both hands when installing the roller

pressure adjusting screw .

2. Clearance adjustment between upper feed roller and throat plate

(1) If the standard clearance adjustment seems to be improper, loosen

two setscrews and raise the upper feed roller pressing shaft .

Insert the clearance gauge in between the upper face of the throat

plate and the lower position of the upper feed roller . Then,

lower the upper feed roller pressing shaft .

(2) Tighten two setscrews under the condition that the bottom face

of the guide finger is put on to keep contact with the upper face of

the guide support block .

(3) In the state as seen from behind, confirm that the vertical clearance

of the upper feed roller is maintained at the standard level in

conjunction with the throat plate

(4) In the state as seen from behind, confirm that the front and rear

right/left clearances on the right side of the upper feed roller are

uniformly maintained in conjunction with the feed dog .

(Caution) The right/left clearance between the upper feed roller

and the feed dog shall be confirmed while the

feed dog is positioned at the highest level.

3. Adjustment of parallelism between upper feed roller and feed dog

(1) Loosen the setscrew and turn the upper feed roller pressing shaft

to the right and left to confirm that uniform clearances are retained

in front / rear and right / left positions between the upper feed roller

and the feed dog . Since then, tighten the setscrew .

4. Adjustment to eliminate right and left rattling in the upper feed roller

(1) If there is right and left rattling in the upper feed roller , loosen the

setscrew and hold the guide finger to eliminate right and left

rattling, using the right/left guide plate . Since then, tighten the

setscrew .

o If the upper feed roller touches

the throat plate and there is too

much pressure, this will be a

cause of cutting off the .

o If the clearance is too much

between the upper feed roller

and the throat plate , this will

be a cause of failure in supplying

the

o If pressure of the upper feed roller

is too weak for the material

cloth, uneven feeding may arise.

Adjustment Procedures Results of Improper Adjustment

Loading...

Loading...