(6) Lubrication

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

Standard adjustment

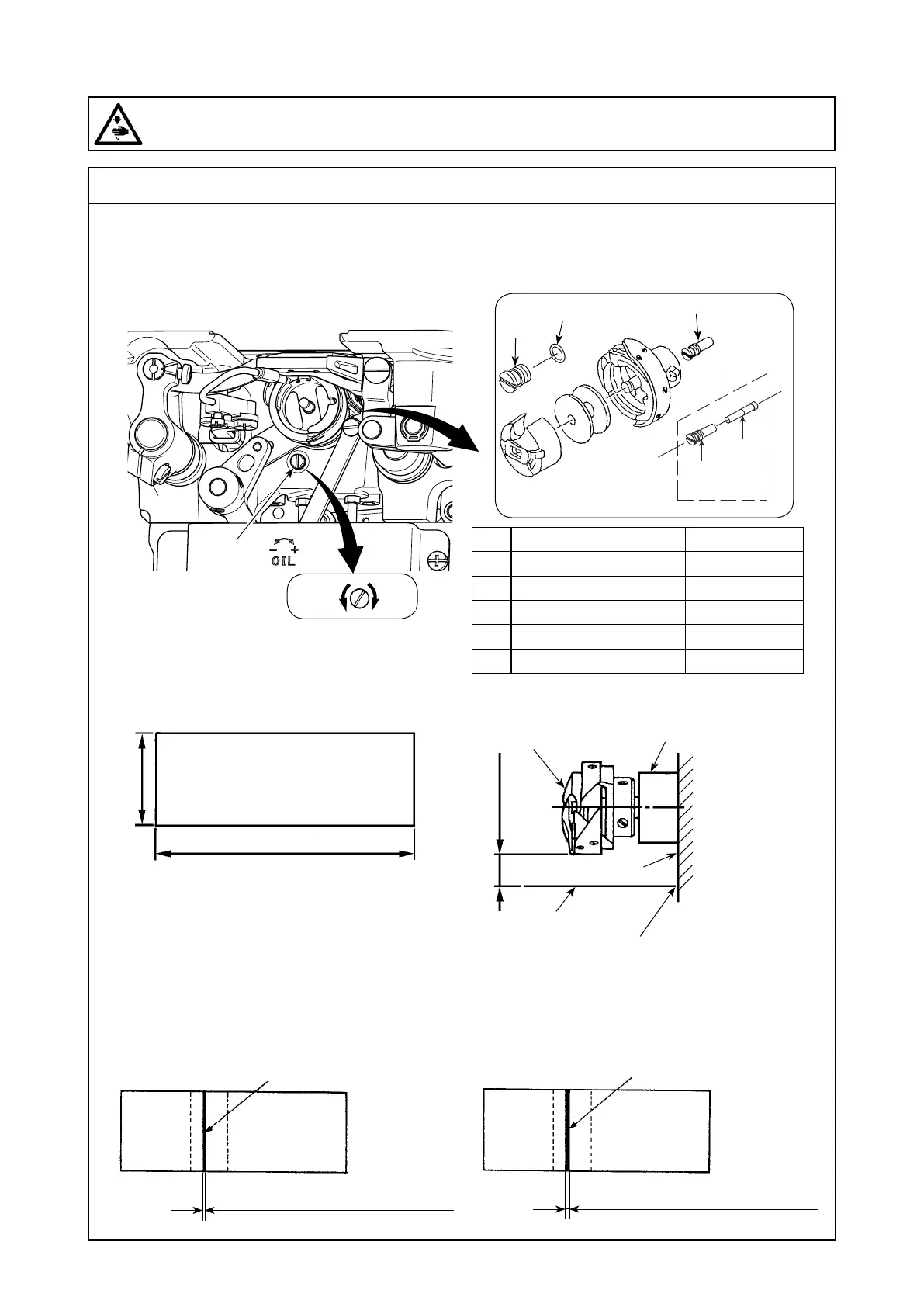

5) Adjusting the amount of oil in the hook

6) Hook oil adjustment procedures

7) Essentials for hook oil adjustments

8) Replacement of the hook shaft oil wick

DESCRIPTION Part No.

❷

OIL SEAL SCREW ASM.

22916555

❸

SET SCREW

22916506

❹

OIL WICK

11015906

❺

FRONT SCREW

11079506

❻

RUBBER RING

RO036080200

❷

❻

❺

❶

Less

Much

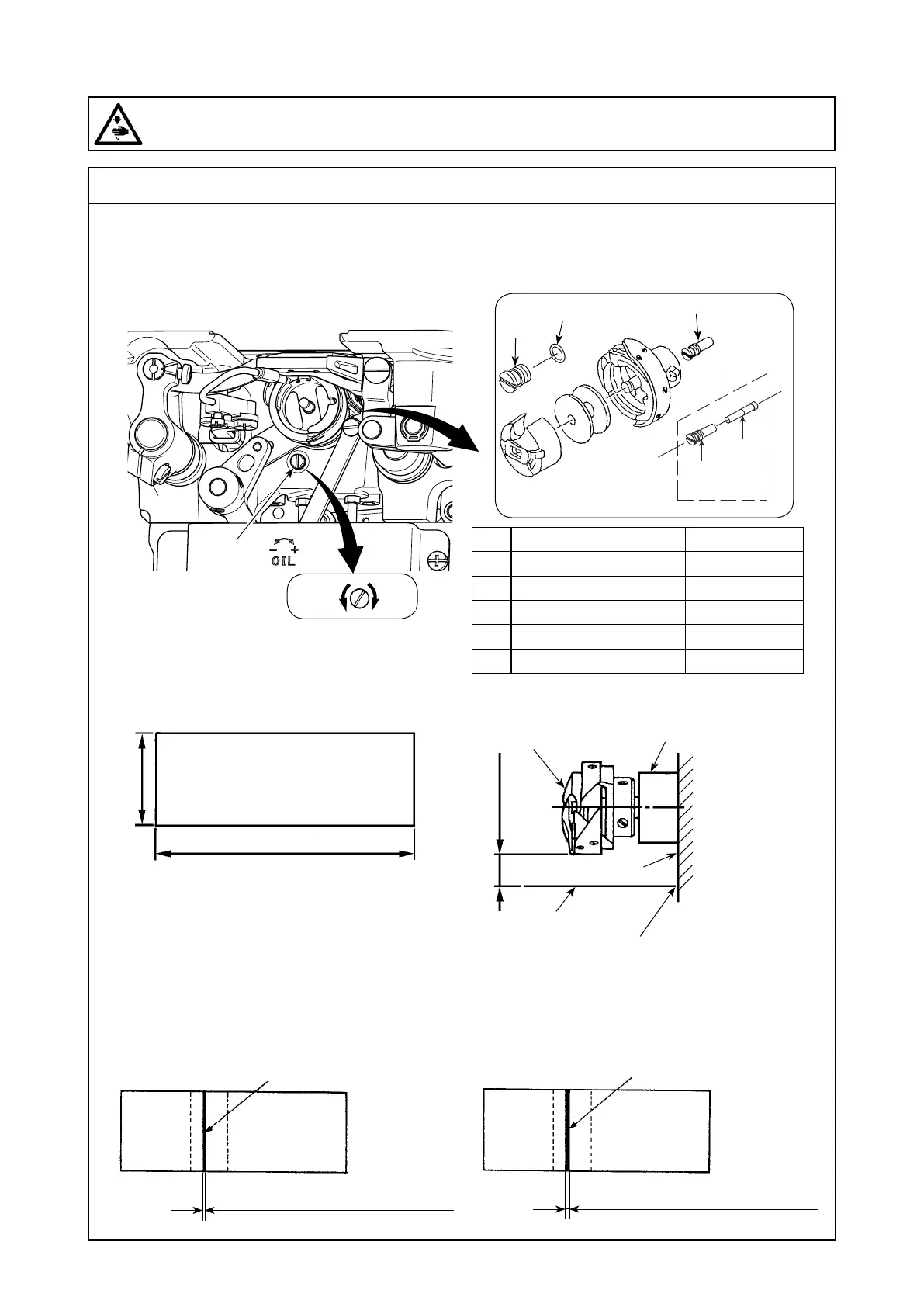

• DDL-9000C-SMS : 0.5 to 1mm

• DDL-9000C-SSH : 1 to 3mm

• DDL-9000C-SMS : 1 to 1.5mm

• DDL-9000C-SSH : 2 to 4mm

❷

❹

❸

– 20 –

Oil quantity (trace) checking paper

Oil quantity (trace) checking paper

Approx. 25mm

Lower shaft front metal

Bed

Hook

3 to 10mm

To be applied to the bed wall.

Oil trace checking paper

Approx. 70mm

* Unnecessary to worry about the quality of paper.

* Apply the oil quantity (trace) checking paper to hooks

lower side and check it from a distance of 3 to 10mm.

Oil quantity (small)

Oil quantity (large)

Oil sprinkles from the hook

Oil sprinkles from the hook

Loading...

Loading...