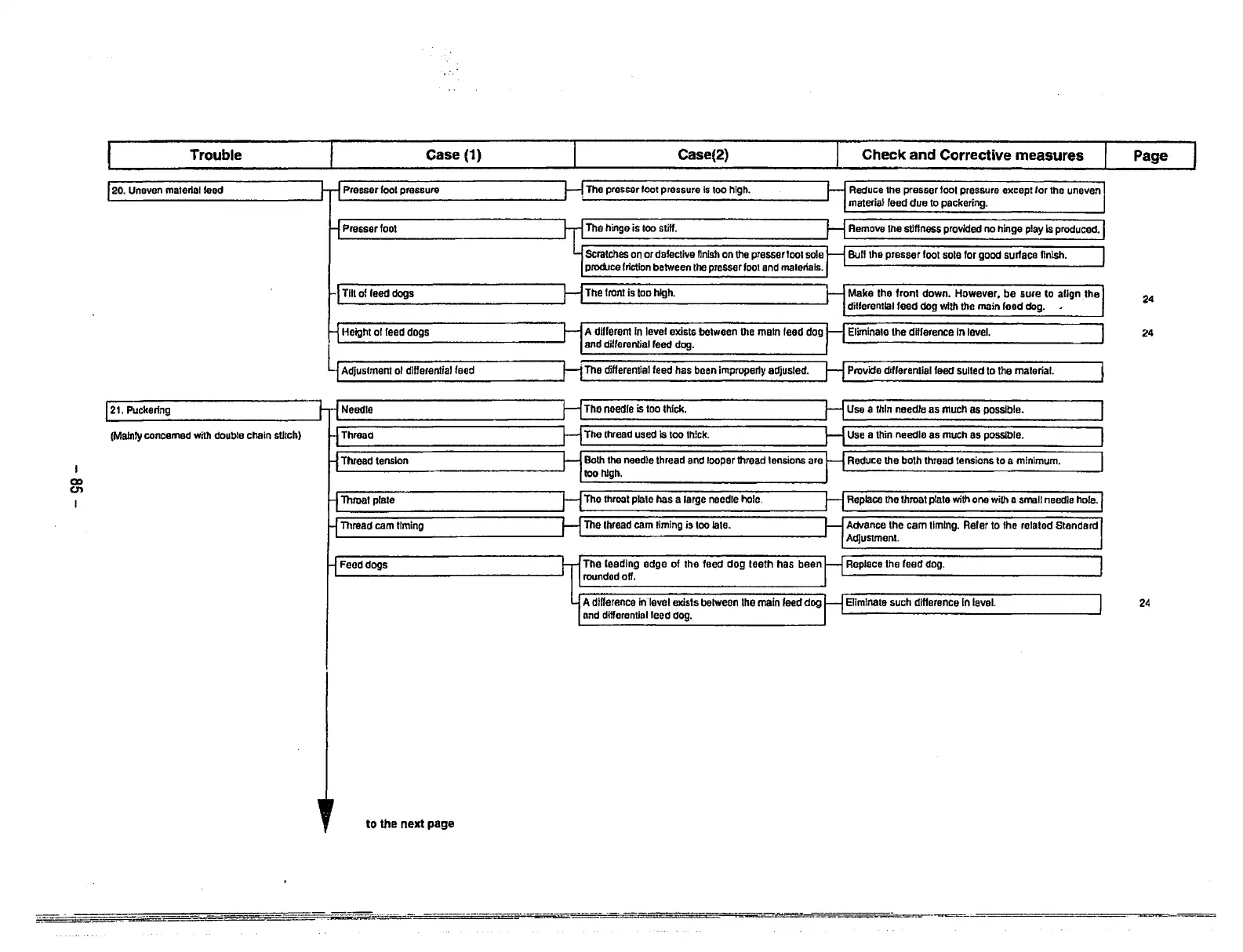

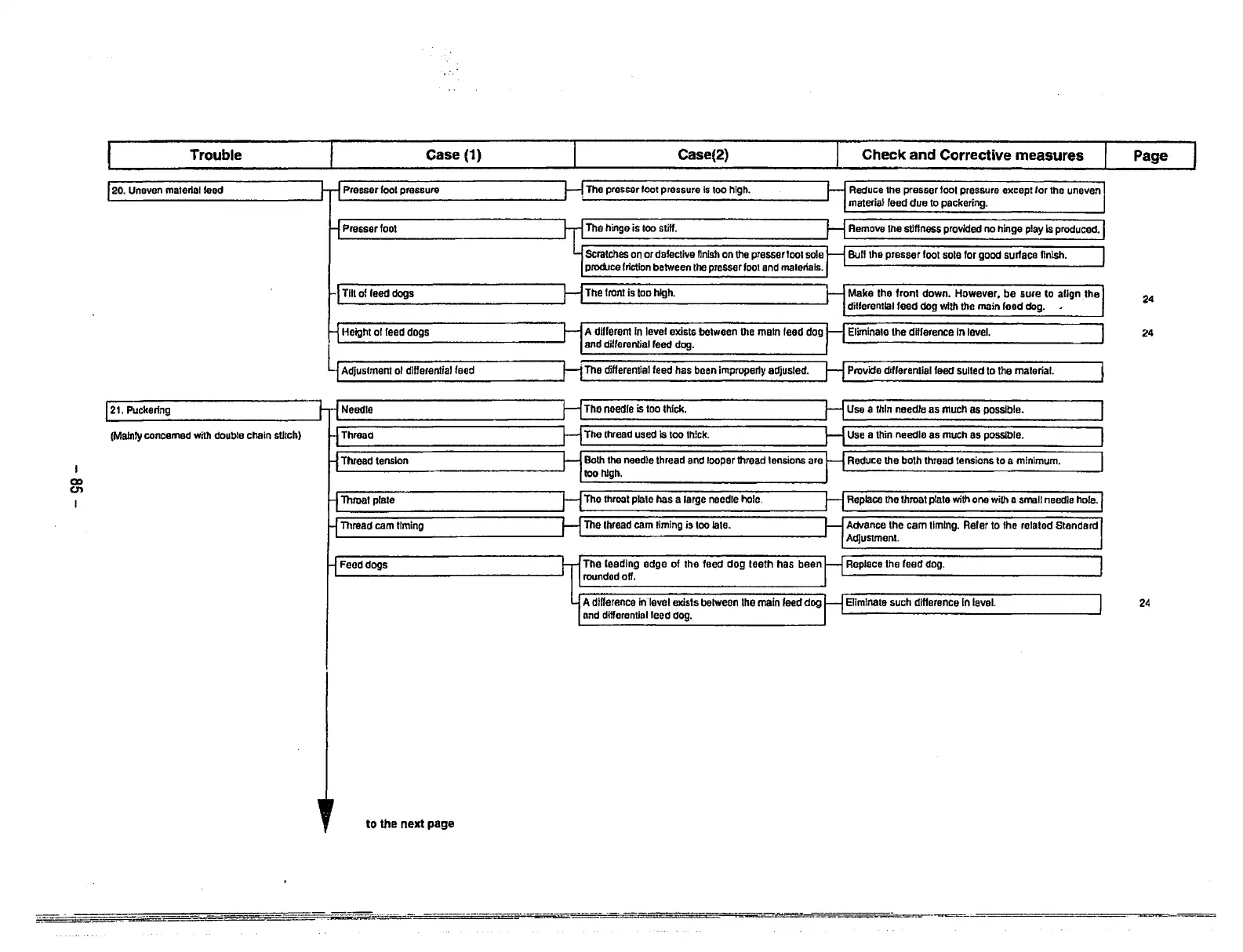

Trouble

Case (1)

Case(2)

Check and Corrective measures

Page

20.

Uneven

material lead

Presser fool pressure

The

presser foot pressure

Is

too

high.

Reduce

the presser loot pressure except for the uneven

material

feed

due

to

packering,

Presser

foot

The

hinge is

too

stiff.

Remove

the sllffness provided

no

hinge

play

is

produced.

Scratches

on

or dafective

flnlsh

on

the

presser loot

sole

Buff the presser foot sole for good surface finish.

produce

friction

between lhe presser

foot

and

materials.

TIit of

feed

dogs

The

front is too high.

Make the front down. However, be sure to align the

24

differential feed dog wllh

the

main feed dog.

Height

of

feed

dogs

A different

In

level exists between the main teed

dog

Eliminate

the difference

In

level.

24

and

dilferenlial

feed

dog.

Adjustment ol differential

feed

The

differential

feed

has

been

improperly adjusted.

Provide differential feed suited to

the

material.

21.

Puckering

Needle

The

needle

is too thick.

Use

a

thin

needle

as

much

as

possible.

(Malnly

concemed

with

double chain

stJIch)

Thread

The

thread

used

is

too

thick.

Use

a thin needle

as

much

as

poSSlble.

Thread tension

Bolh

the

needle thread

and

looper thread tensions are

Reduce

the both thread tensions to a minimum.

00

too

high.

c.n

Throat plate

The

throat

plate has a large

needle

hole.

Replace

the

throat plate

with

one

with

a small needle hole.

Thread

cam

timing

The

thread

cam

timing is too late.

Advance the cam timing. Refer to !he related Standard

Adjustment.

Feed

dogs

The leading edge of the feed dog teeth has been

Replace

the feed

dog.

rounded

off.

A difference

in

level exists

between

lhe

main

feed

dog

Ellmlnate such difference in level.

24

and

differential

feed

dog.

to the next page

Loading...

Loading...