MULTICAL®602

KamstrupA/S∙TechnicalDescription∙5512‐931_N1_GB

11.2016

103

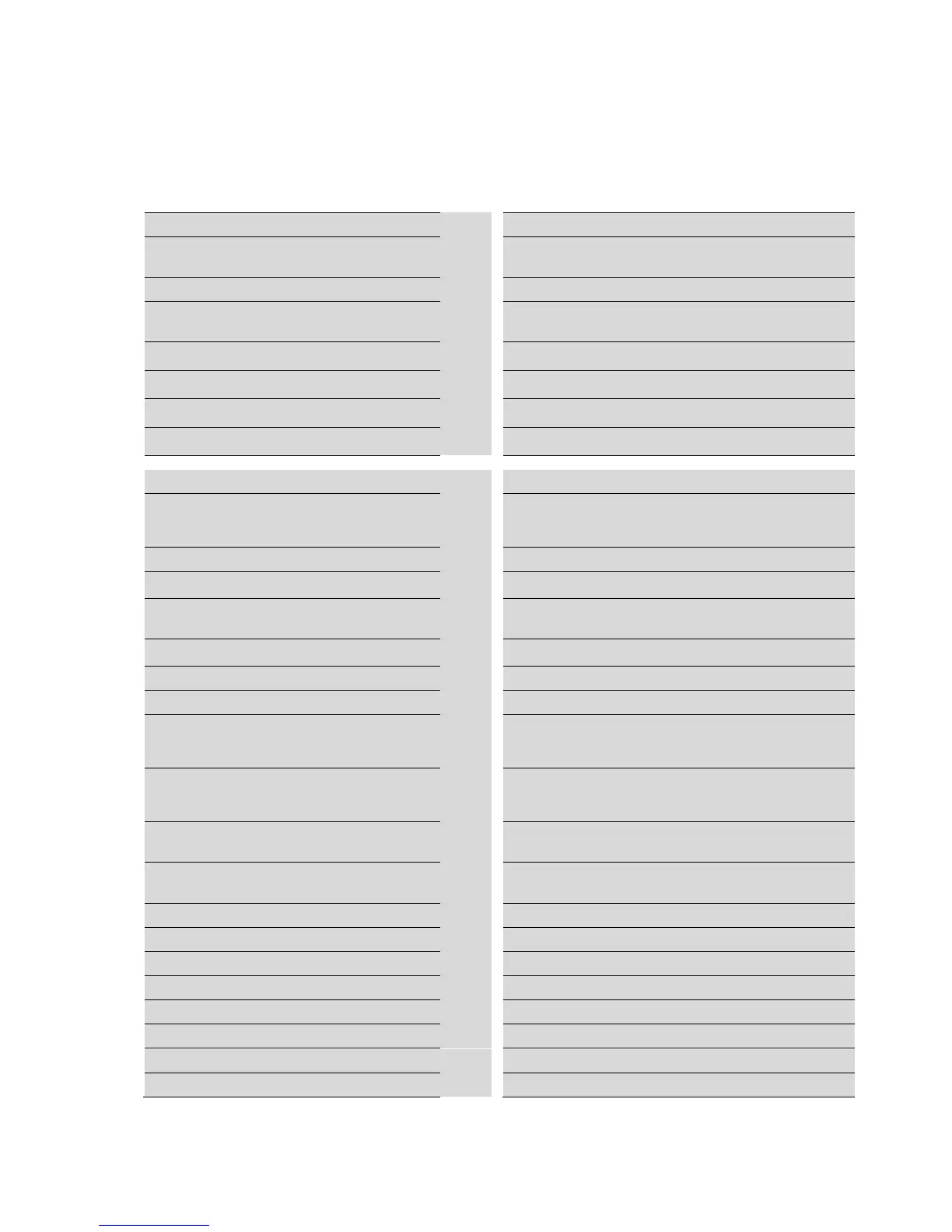

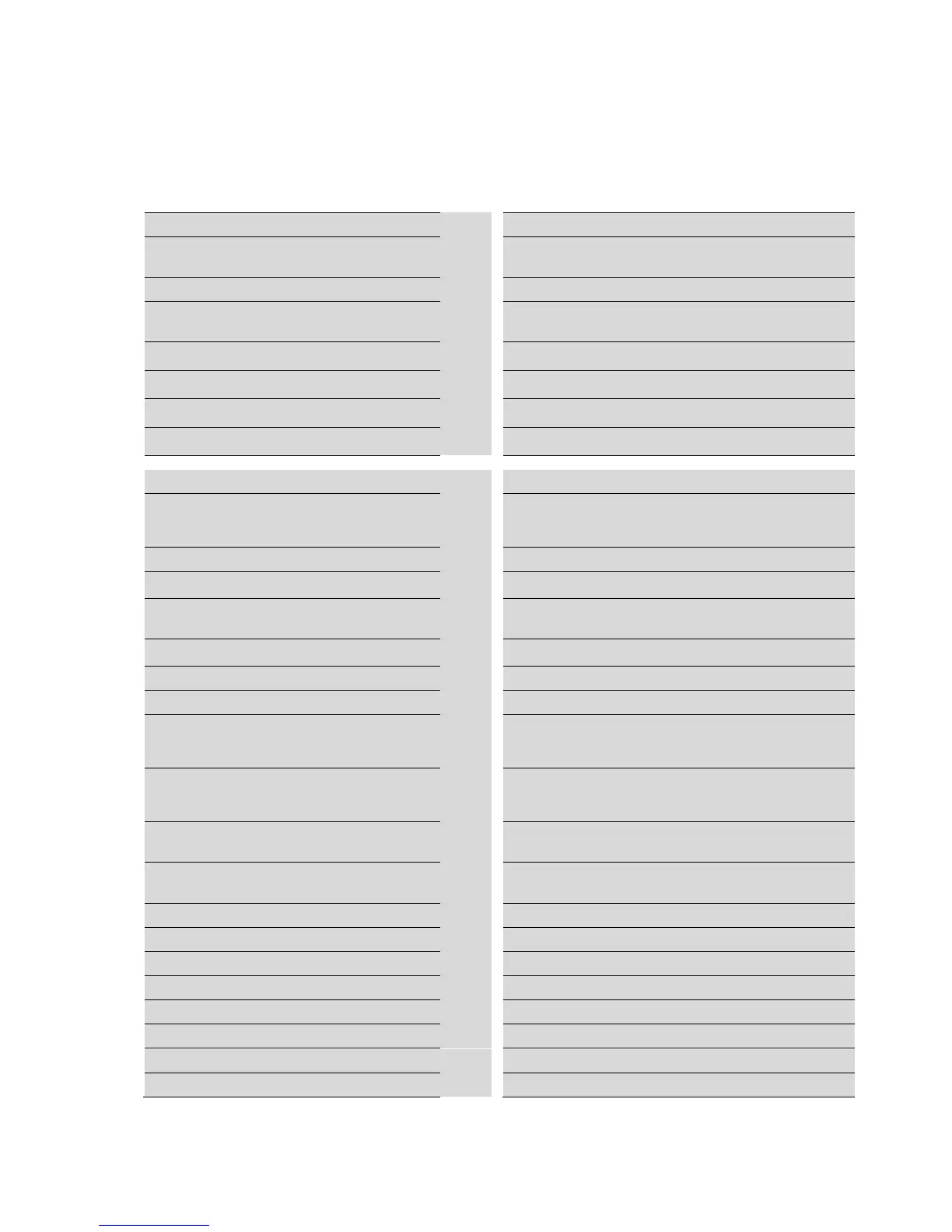

10.3 Retrofitting modules

Top as well as base modules for MULTICAL

602 can be supplied separately for retrofitting. The modules are

configured from the factory and ready to be mounted. Some of the modules, however, need individual configuration

after installation, which can be carried out by means of METERTOOL.

Top module

Possible configuration after installation

Energy calculation

2

Magnification, hysteresis and possible flow cut-off must be adjusted

during commissioning. All parameters and limits can be changed via

METERTOOL

Data output

5

Primary and secondary M-Bus addresses can be changed via

METERTOOL or M-Bus. Furthermore, monthly logger data can be

selected instead of yearly logger data by means of M-Bus

Volume

9

N/A

2 pulse outputs for CE and CV + scheduler

A

Configuration of pulse outputs.

RTC + 2 pulse outputs for CE and CV + prog. data log.

B

Configuration of pulse outputs and logger interval.

2 pulse outputs for CE and CV

C

Configuration of pulse outputs.

Base module

Pulse values of VA and VB are changed via METERTOOL

M-Bus/pulse inputs

20

Pulse values of VA and VB are changed via METERTOOL

Primary and secondary M-Bus addresses can be changed via

METERTOOL or M-Bus. Furthermore, monthly logger data can be

selected instead of yearly logger data via M-Bus

Radio Router/pulse inputs

21

Pulse values of VA and VB are changed via METERTOOL

Prog. data logger + RTC + 4…20 mA inputs + pulse inputs

22

Pulse values of VA and VB, and logger interval are changed via

METERTOOL

0/4…20 mA outputs

23

Config data must be programmed into the calculator by means of

METERTOOL in case of retrofitting. Furthermore, all parameters can be

changed via METERTOOL

LonWorks + pulse inputs

24

Pulse values of VA and VB are changed via METERTOOL. All other

configurations via LonWorks

Radio + pulse inputs (internal antenna)

25

Pulse values of VA and VB are changed via METERTOOL

Radio + pulse inputs (external antenna)

26

Pulse values of VA and VB are changed via METERTOOL

M-Bus module with alternative registers + pulse inputs

27

Pulse values of VA and VB are changed via METERTOOL.

Primary and secondary M-Bus addresses can be changed via

METERTOOL or M-Bus. Furthermore, monthly logger data can be

selected instead of yearly logger data via M-Bus

M-Bus module with medium data package + pulse inputs

28

Pulse values of VA and VB are changed via METERTOOL.

Primary and secondary M-Bus addresses can be changed via

METERTOOL or M-Bus. Furthermore, yearly logger data can be selected

instead monthly logger via M-Bus.

M-Bus module with MC-III data package + pulse inputs

29

Pulse values of VA and VB are changed via METERTOOL.

Primary and secondary M-Bus addresses can be changed via

METERTOOL or M-Bus.

Wireless M-Bus + pulse inputs

30/31/

35/36/

38/39

Pulse values of VA and VB are changed via METERTOOL

ZigBee 2.4 GHz internal antenna + pulse inputs

60

Pulse values of VA and VB are changed via METERTOOL

Metasys N2 (RS485) + pulse inputs

62

Pulse values of VA and VB are changed via METERTOOL

SIOX module (Auto detect Baud Rate)

64

N/A

BACnet MS/TP + pulse inputs

66

N/A

Modbus RTU + pulse inputs

67

N/A

GSM/GPRS module (GSM6H)

80

N/A

3G GSM/GPRS modul (GSM8H)

81

N/A

High Power Radio Router + pulse inputs

84

Pulse values of VA and VB are changed via METERTOOL

Loading...

Loading...