EN

38

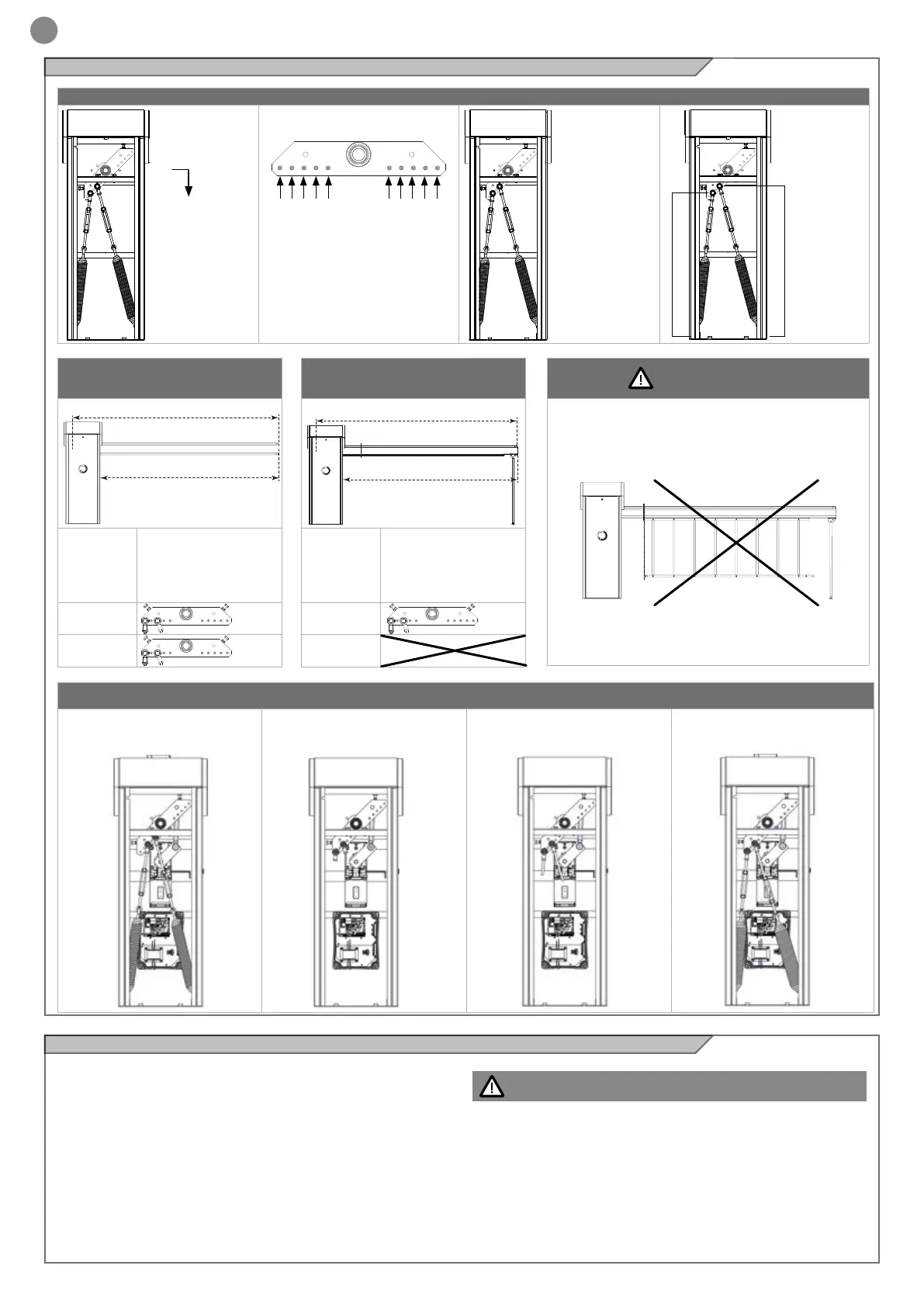

SPRING FIXING

1 - Remove the springs, the

spring tensioners and the threa-

ded bars.

2 - Move and secure the articu-

lated heads in positions 1 and 3.

3 - Screw in the new threaded

bars: the short bar 1 and the

long bar 3.

4 - Fix the new springs with ten-

sioners and a 45° balance arm..

BAR + RUBBER PROFILE

+ MOBILE SUPPORT

L =

BAR LENGTH

(mm)

POSITION

7400

8400

5.9 - ALT624K with ASTL8 Accessories and bar weight balancing

L= LUNGHEZZA ASTA

PL=LUNGHEZZA PASSAGGIO (L-350 mm)

KEY

BAR + RUBBER PROFILE

L =

BAR LENGTH

(mm)

POSITION

7400

8400

ATTENTION !

L= LUNGHEZZA ASTA

PL=LUNGHEZZA PASSAGGIO (L-350 mm)

1 52 43 34 25 1

HOLE NUMBERS

V

D

V

D

1

2

1V1

3D2

1V1

3D2

1V1

3D2

NO KIT FENCE

example of spring

positioning and type:

3D1

3 = HOLE NUMBER

D = SPRING POSITION

1 = SPRING TYPE

SPRING POSITION

V = vertical position

D = diagonal position

SPRING TYPE

1=spring + short

tie rod

2=spring + long

tie rod

N.B. The LED strips are always included in the balance system

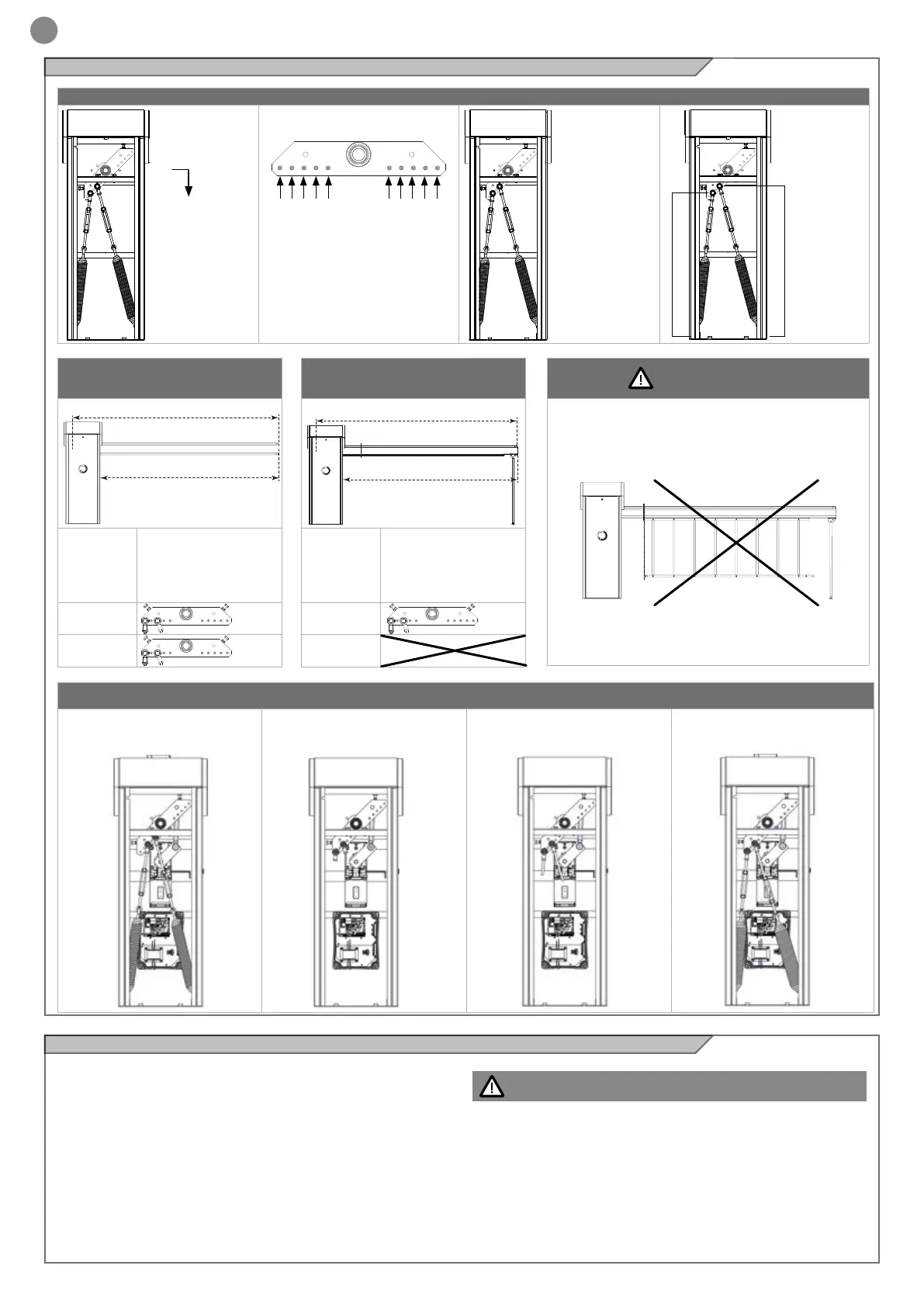

5.10 - Balancing

To balance the bar proceed as follows:

- disconnect the power supply and release the bar as described in

paragraph 5.3

- open the barrier door (Fig. 7)

- move the bar manually, keeping its opening angle at approximately

45°

- check that the balancing of the bar opened to an angle of 45° is en-

sured, i.e. the springs must be able to correctly balance the weight

of the bar (Fig. 19)

- if the bar balance is not ensured, bring the bar back to a vertical po-

sition and work the tensioners to increase or decrease the tension of

the springs until the bar reaches a stable balanced condition at 45°

Stretch the springs progressively so that both can equally con-

tribute to balancing

- tighten the tensioner lock nuts to prevent them from becoming loo-

se during normal operation and lock the bar again

- restore the power supply and check that the automation system is

working properly

We recommend to check the correct balance every 6 months or

every 50,000 opening/closing cycles

ATTENTION !

L=BAR LENGTH

L=BAR LENGTH

PL=PASSAGE WIDTH (L-350 mm)

PL=PASSAGE WIDTH (L-350 mm)

Loading...

Loading...