35

EN

35

EN

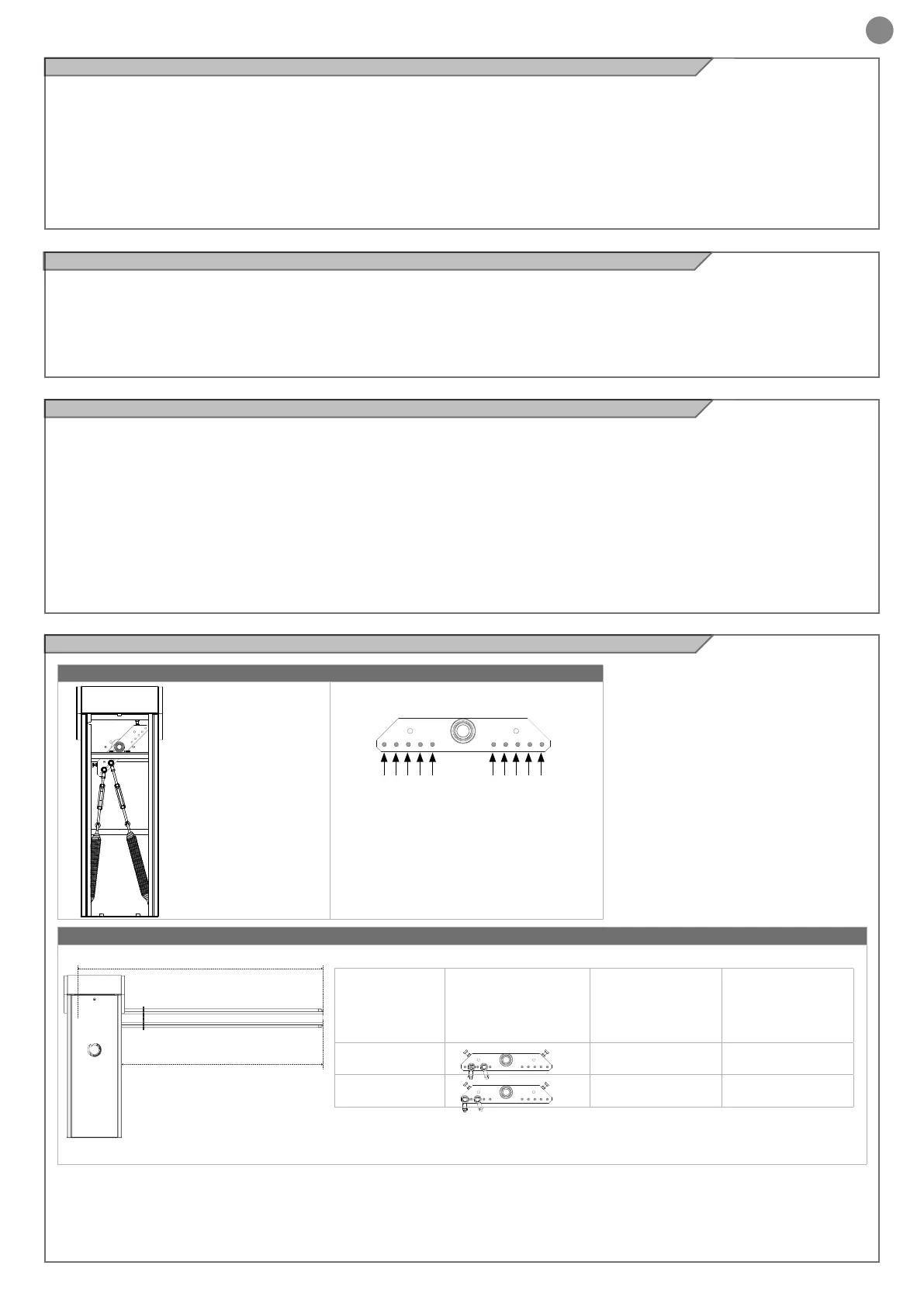

5.3 - Bar release

If it is necessary to manually adjust the barrier bar, proceed as follows

(Fig. 17):

- Disconnect the power supply.

- Insert the supplied release key and remove the pad lock, insert the

Allen key and rotate it by 90°.

- In this way it is possible to release the internal reducer system to

allow for emergency manoeuvring.

5.4 - Bar angle adjustment

In the event that the bar limit stops must be adjusted, proceed as

follows (Fig. 18):

- Loosen the locknut located on the upper crosspiece of the box

- Adjust the screw to the desired height

- Perform the manual manoeuvre.

- To re-activate the transmission, simply turn the Allen key to return it

to its initial position and then close the lock.

- Now you can restore the power supply and check that everything is

in good working order.

- Re-tighten the locking nut again

- Repeat the operation with the other stop

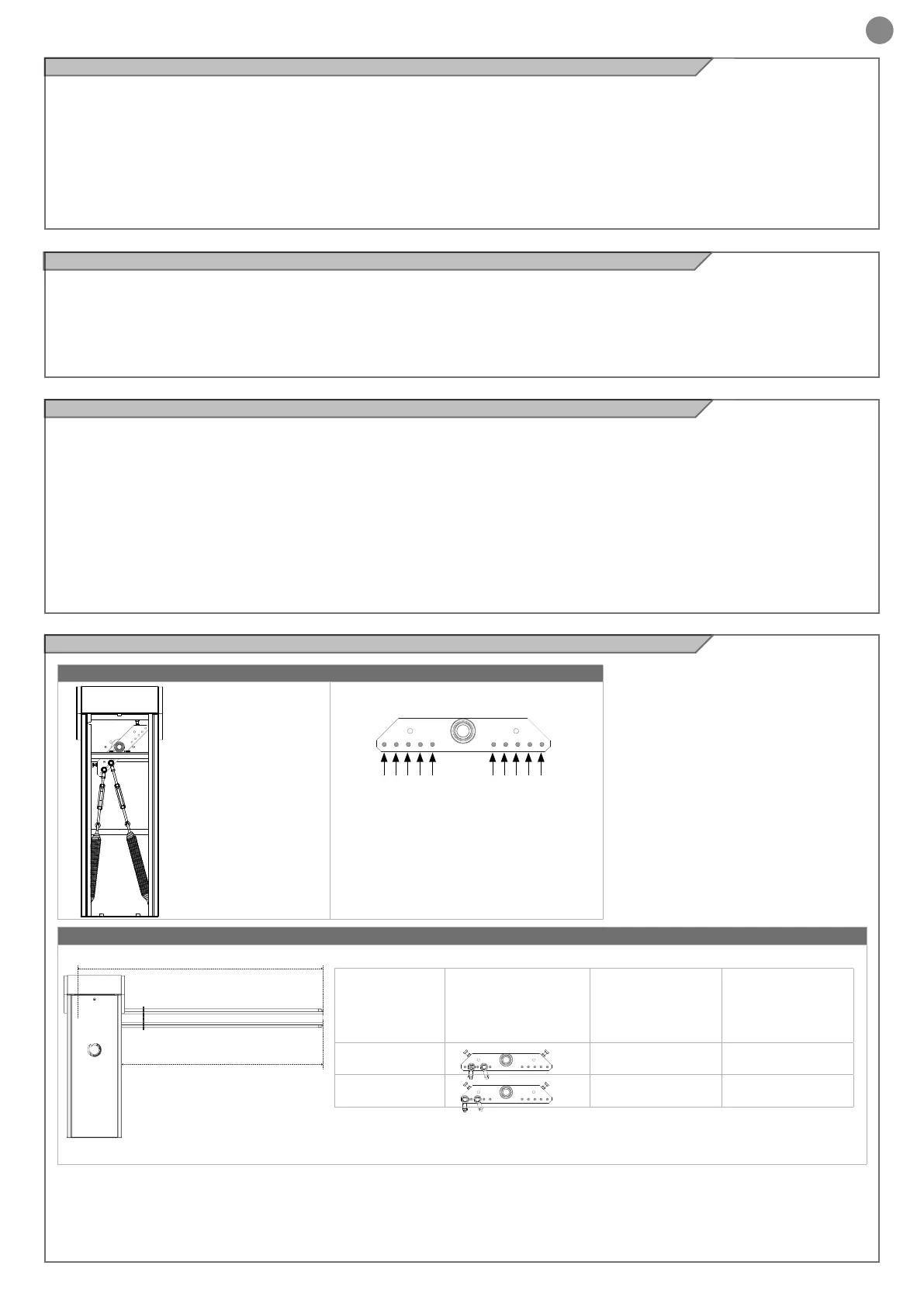

5.6 - ALT324KF Accessories and bar weight balancing

5.5 - Barrier conguration with accessories

Before carrying out, during installation, the rst balancing of the bar,

the barrier must be congured according to the accessories actually

installed.

The following diagrams (Par. 5.6 for ALT324KF, Par. 5.7 for ALT424K,

Par. 5.8 for ALT624K) show the optimal xing positions of the articu-

lated joint heads of the tensioners with respect to the balance lever

for your barrier conguration, i.e. by model (ALT324KF, ALT424K or

ALT624K), by length of the bar and according to the chosen acces-

sories.

It is therefore necessary to compare these positions with the "factory"

ones and if they do not match, loosen the screws that x the articula-

ted heads of the tensioners to the balance lever and reposition them

accordingly:

- starting from the "factory" conguration, install the bar in a vertical

position. Make sure the bar is locked in this position

- identify, on the basis of the following diagrams, the most suitable po-

sition of the articulated joint heads of the tensioners and x them with

the screws to the corresponding holes in the balance lever, tightening

the tensioners by a few turns so as to partially increase the springs'

tension

KEY

ONLY BAR

L= LUNGHEZZA ASTA

PL=LARGHEZZA PASSAGGIO (L-300 mm)

example of spring positioning:

2 + 4 = HOLE NUMBER

L=BAR LENGTH

PL=PASSAGE WIDTH (L-300 mm)

HOLE NUMBERS

3+5

1+3

1 52 43 34 25 1

L = BAR LENGTH

(mm)

POSITION

SUGGESTED VALUE

FOR LS1 PARAMETER

SUGGESTED VALUE

FOR LS2 PARAMETER

2400 52 55

3000 55 68

Loading...

Loading...