When building an enclosure, the enclosure walls should be as rigid as possible. Any flexing in the enclo-

sure will drastically decrease your speakers’ performance. Also, all of the joints and walls in a speaker enclo-

sure should be airtight, including screw holes and wire holes. Any leaks or flexing will cause cancellation,

resulting in reduced output.

Enclosures should be built with very dense and heavy wood. We recommend MDF (medium density fiber-

board) or medite (high density fiberboard). They are rigid, heavy and not porous like some particle boards.

We recommend 3/4” (19mm) MDF although 1/2” (12.5mm) MDF is acceptable for woofers 8” and smaller.

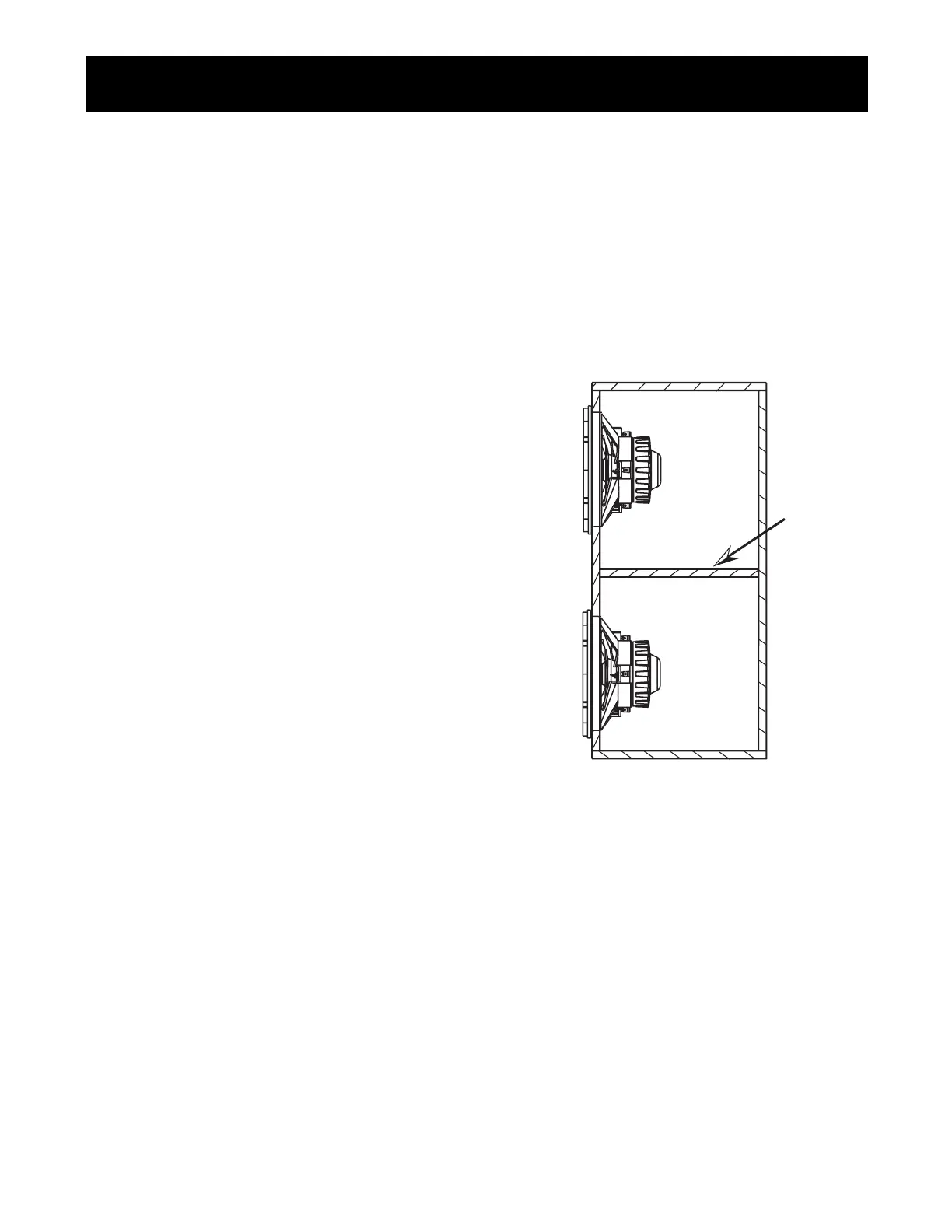

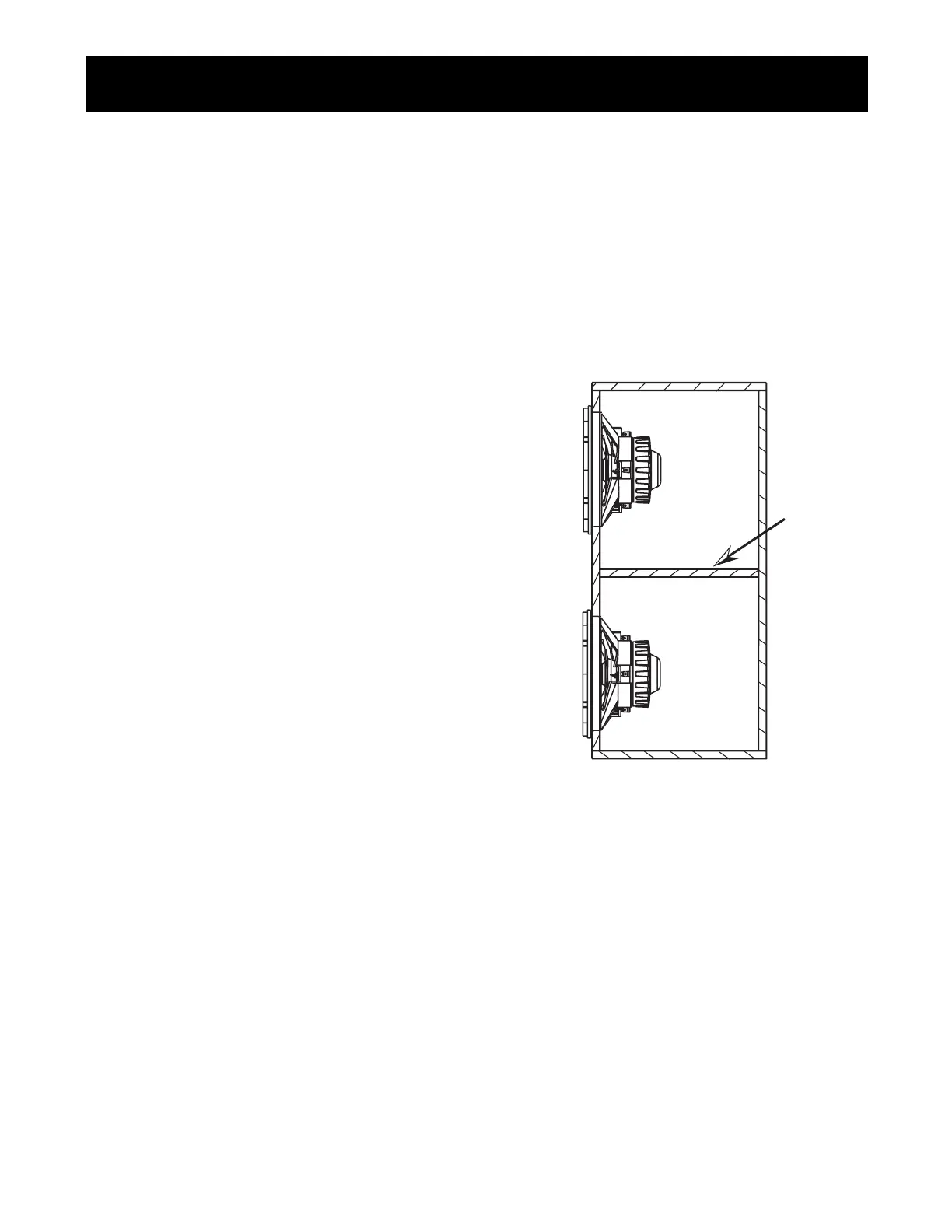

Most enclosures are built for multiple drivers and require sep-

arate chambers for each driver. Dividers are a very important

part of box building because they create strength in the box

and provide an airtight seal between the speakers. Keep in mind

that no two things are created equally (even speakers of the

same size and model!). This will cause drivers in an open cham-

ber to react differently, substantially reducing output and

power handling.

When assembling the box it is very important to glue all joints.

Screws or staples should be placed approximately every 4”

(10cm). Drywall screws work better if they are counter-sunk.

Countersinking makes it easy to fill over the screw heads for

paint or carpet, and improves the appearance of the enclosure.

A quality air staple has been proven to be a good substitute

for counter-sunk drywall screws. Use 1-1/2” (38mm) or 1-5/8”

(41mm) staples at least every 3” (7.5cm) along every seam.

Don’t forget the wood glue. This is much faster and smoother

than using screws.

Glue joints all the way across the wall to provide an airtight

seal. We recommend Titebond or Elmer’s Wood Glue.

It is always a good idea to use corner braces, also called glue blocks, on each joint in an enclosure. Corner

braces are usually made from left-over enclosure wood and measure approximately 1” (2.5cm) wide. The

braces should be glued and screwed or stapled to the walls and caulked on both edges where they meet

the walls. Use silicone caulk to ensure the airtight seal. Don’t use “bathroom tile” type caulk, it won’t do the

job!

Not all corner braces will be the length of the wall they’re attached to. For example, if a wall’s length is

36” (1m), but there is already a corner brace on the adjacent wall, we’d need to deduct one inch (2.5cm) so

that the braces fit together- not overlap. Deduct two inches (5cm) from a brace’s length if there are braces

on both adjacent walls.

Box Building & Mounting Hints

Loading...

Loading...