4-13

September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

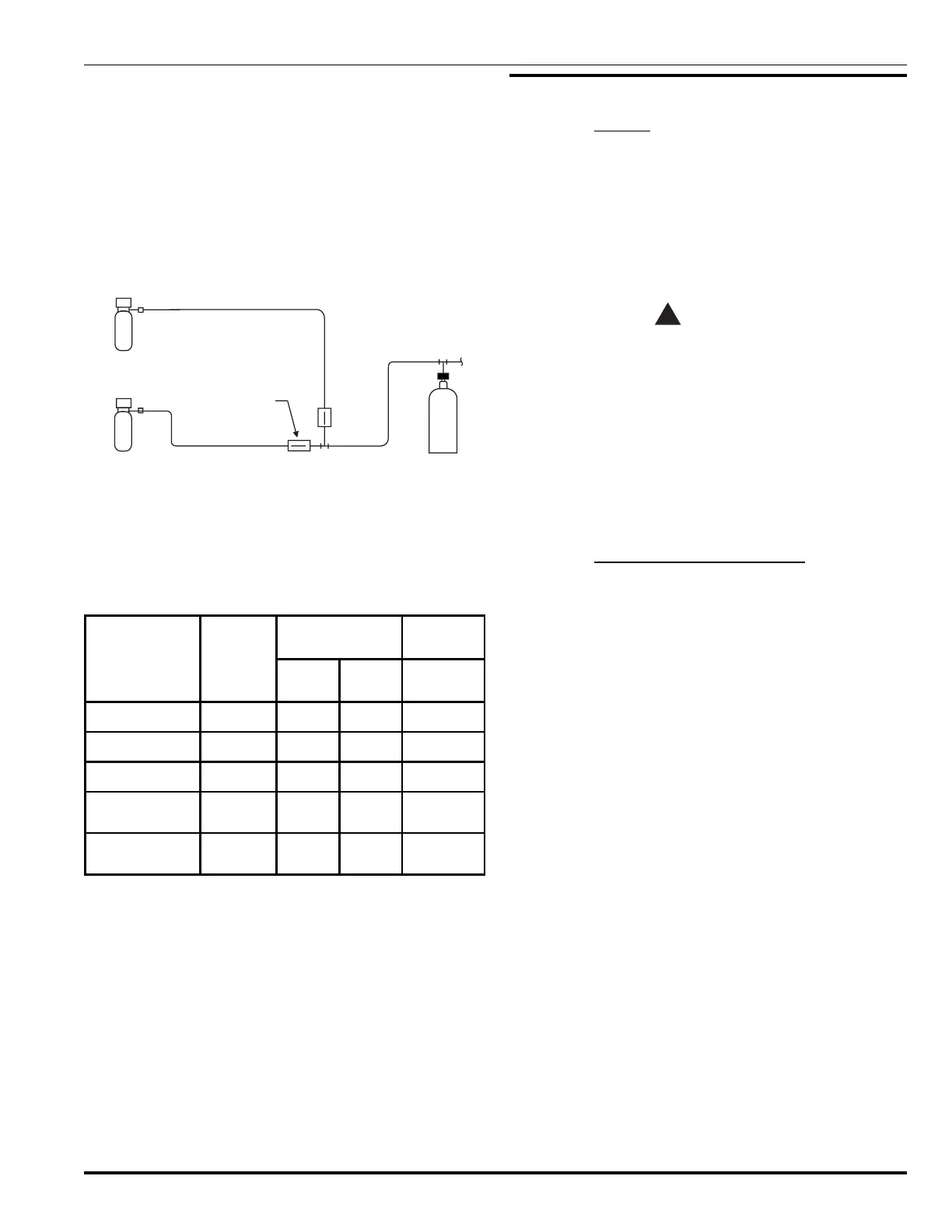

4-2.5.5 USING MULTIPLE NITROGEN CYLINDERS

Two or more remotely located pilot nitrogen cylinders can

be used to actuate the FM-200 systems described in Para-

graphs 4-2.5.3 and 4-2.5.4, provided that:

1/4" check valves (P/N 264985) shall be installed

at the intersection of each pilot line to the main ac-

tuator line (see Figure 4-9).

The total length of actuator line, from each nitro-

gen pilot cylinder to the FM-200 cylinders shall not

exceed the limitation established.

N PILOT

CYLINDER

2

N PILOT

CYLINDER

2

¼” CHECK VALVE

P/N WI-264985-000

FM-200

CYLINDER

Figure 4-9. Multiple Pilot Nitrogen Actuation Cylinders

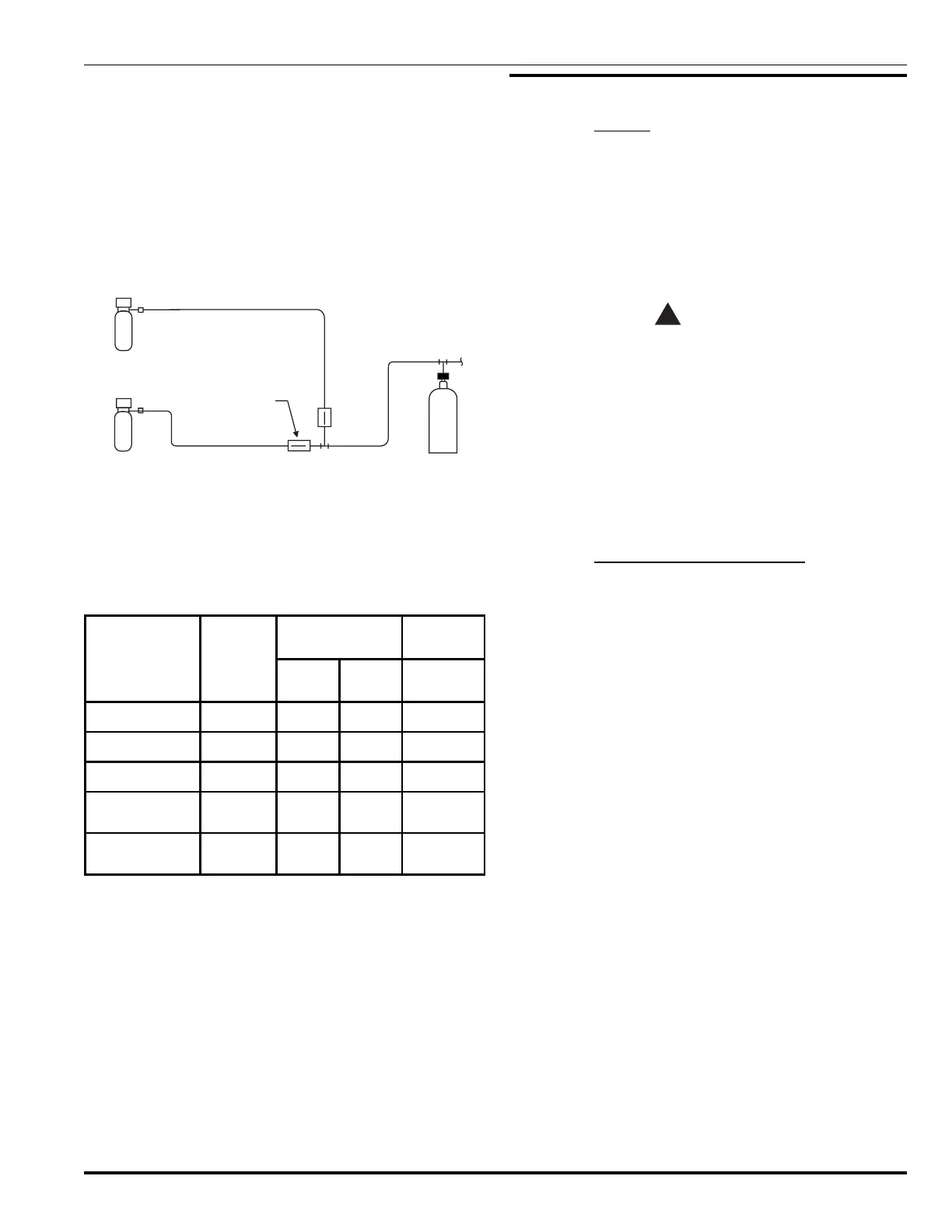

4-2.5.6 CORNER PULLEY AND

CABLE LIMITATIONS

Table 4-7 lists corner pulley and cable length limitations.

Table 4-7. Corner Pulley and Cable Limitations

Control Head

Type

Part

Number

Pulley

Max. Cable

Length

P/N

803808

P/N

844648

ft.

Cable Operated 979469 15 30 100

Electric/Cable 895630 6 30 100

Electric/Cable 895627 6 30 100

Electric/Cable,

Explosion-Proof

897494 6 30 100

Electric/Cable,

Explosion-Proof

897560 6 30 100

4-2.5.7 PRESSURE TRIP LIMITATIONS

The maximum load to be attached to pressure trip

(P/N 874290) is 100 lb. (45.3 kg, based on a minimum pres-

sure of 75 PSIG [5.17 bar gauge] at the pressure trip).

4-3 EQUIPMENT INSTALLATION

4-3.1 General

All Kidde FM-200 equipment must be installed to facili-

tate proper inspection, testing, manual operation, re-

charging and any other required maintenance as may

be necessary. Equipment must not be subject to severe

weather conditions or mechanical, chemical or other

damage that could render the equipment inoperative.

Equipment must be installed in accordance with

NFPA Standard 2001, current edition.

WARNING

!

The FM-200 cylinder/valve assemblies must be

handled, installed and serviced in accordance

with the instructions contained in this

paragraph and Compressed Gas Association

(CGA) pamphlets C-1, C-6 and P-1. CGA

pamphlets may be obtained from: Compressed

Gas Association, 1235 Jefferson Davis

Highway, Arlington, VA 22202. Failure to follow

these instructions can cause FM-200 cylinders

to violently discharge, resulting in severe injury,

death and/or property destruction.

4-3.2 Distribution Piping and Fittings

4-3.2.1 THREADS

Threads on all pipe and fittings must be tapered threads

conforming to ANSI Specification 8-20.1. Joint compound,

tape or thread lubricant must be applied only to the male

threads of the joint.

4-3.2.2 PIPE

Piping must be of noncombustible material having physical

and chemical characteristics, such that its integrity under

stress can be predicted with reliability. The computer flow

program has only been verified for the specific types and

schedule of pipe and fittings covered in this manual. There

is a risk that the system may not supply the required quan-

tity of agent in unbalanced systems when other pipe types

and fittings are used.

Loading...

Loading...