5-1September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

CHAPTER 5

MAINTENANCE

5-1 INTRODUCTION

This chapter contains maintenance instructions for the

Kidde FM-200

®

ECS Series Engineered Fire Suppression

System. These procedures must be performed regularly in

accordance with regulations. If problems arise, corrective

action must be taken.

5-2 MAINTENANCE PROCEDURES

WARNING

!

FM-200 and nitrogen cylinder valve assemblies

must be handled, installed, inspected and

serviced only by qualified and trained personnel

in accordance with the instructions contained

in this manual and Compressed Gas

Association (CGA) pamphlets C-1, C-6 and P-1.

CGA pamphlets my be obtained from

Compressed Gas Association, Crystal Square

Two, 1725 Jefferson Davis Highway, Arlington,

VA 22202-4102.

Before performing these maintenance

procedures, refer to the Material Safety Data

Sheets and Safety Bulletins in the appendices

of this manual.

5-2.1 General

A regular program of systematic maintenance is essential

for continuous, proper operation of all FM-200 systems. A

periodic maintenance schedule must be followed and an

inspection log maintained for ready reference. As a mini-

mum, the log must record:

1. Inspection interval,

2. The inspection procedure performed,

3. Maintenance performed, if any, as a result of in-

spection, and

4. The name of inspector performing the task.

If the inspection indicates areas of rust or corrosion, imme-

diately clean and repaint the area. Perform cylinder hydro-

static pressure testing in accordance with Paragraph 5-5

of this manual.

5-3 PREVENTIVE MAINTENANCE

Perform preventive maintenance per Table 5-1.

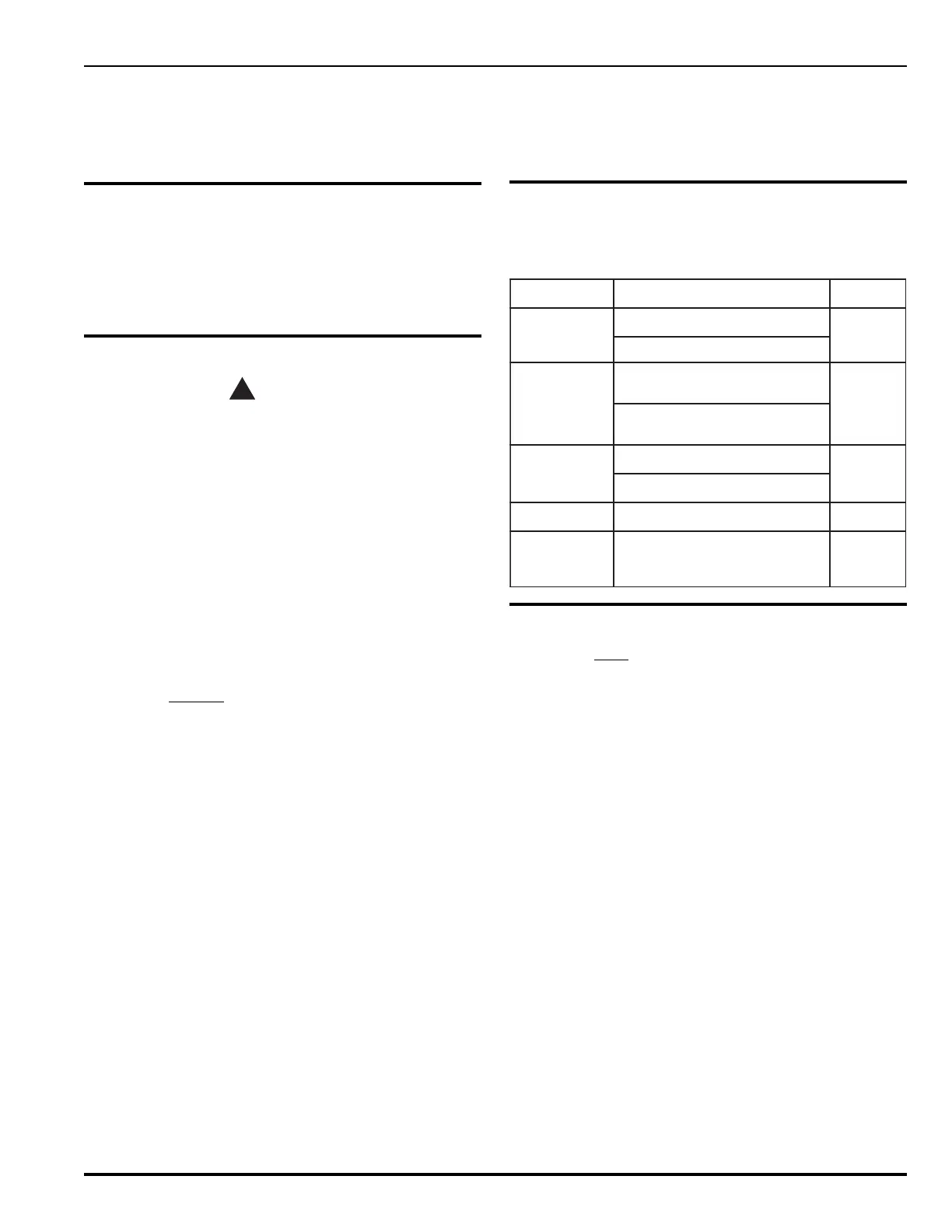

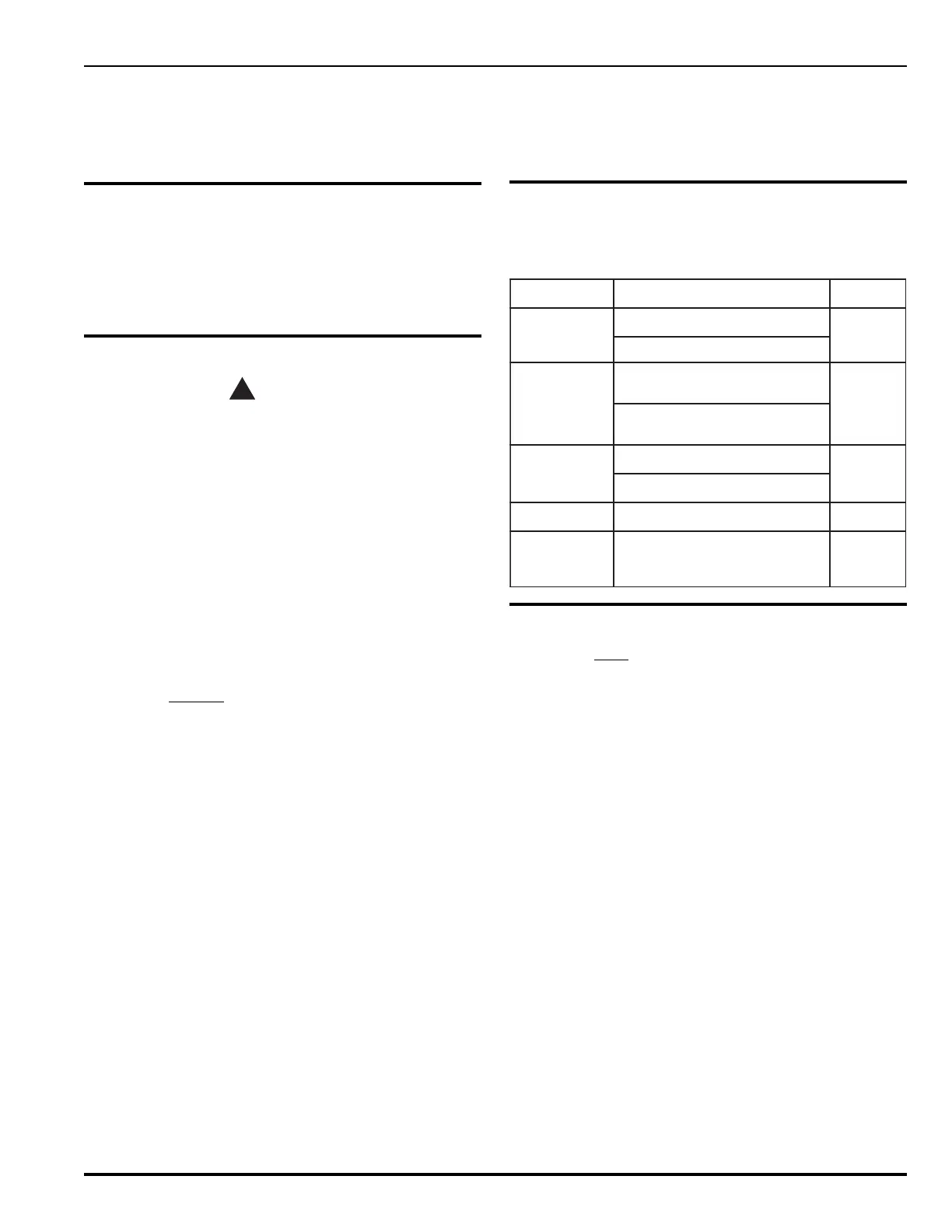

Table 5-1. Preventive Maintenance Schedule

eludehcStnemeriuqeRhpargaraP

yliaD

serusserprednilyc002-MFkcehC

1.4-5

serusserprednilycnegortinkcehC

ylhtnoM

metsysaeradrazahtcepsnI

stnenopmoc

2.4-5

dnasthgiewrednilyc002-MFkcehC

serusserp

yllaunnA-imeS

sehctiwserus

serptseT

3.4-5

sdaehlortnoccirtceletseT

sraeY2yrevE

gnipipnoitubirtsidtuowolB4.4-5

sraeY5yrevE

dnarednilycne

gortindna002-MF

tseterusserpcitatsordyhesohelbixelf

noitcepsniro/dna

dna5-5

1.4-6

5-4 INSPECTION PROCEDURES

5-4.1 Daily

5-4.1.1 CHECK FM-200 CYLINDER PRESSURE

Check the FM-200 cylinder pressure gauges for proper op-

erating pressure (refer to Table 3-1). If the pressure gauge

indicates a pressure loss (adjusted for temperature) of more

than 10%, or loss in agent quantity shown on cylinder valve

of more than 5%, it shall be refilled. Remove and recharge

the cylinder as instructed in Paragraphs 5-7 and 6-3.

5-4.1.2 CHECK NITROGEN CYLINDER

PRESSURE

Check the nitrogen cylinder for proper operating pressure.

If the pressure loss (adjusted for temperature) exceeds

10%, recharge with nitrogen to 1800 PSIG at 70°F

(124 bar gauge at 21°C).

Loading...

Loading...