5-7September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

5-5.1 Cylinders Continuously in Service

Without Discharge

These cylinders are governed by NFPA 2001 regulations.

Cylinders in continuous service without discharge require

a complete external visual inspection every five years in

accordance with Compressed Gas Association Pamphlet

C-6, Section 3 except that the cylinders need not be emp-

tied or stamped while under pressure. Record date of in-

spection on record tag attached to each cylinder. Where

the visual inspection shows damage or corrosion, the cyl-

inder shall be emptied, retested and restamped in accor-

dance with DOT CFR Title 49, Section 173.34.

5-5.2 Discharged Cylinders of Charged Cylinders

that are Transported

These cylinders may come under NFPA 2001 requirements,

or, in the case of shipment of charged cylinders, DOT, fed-

eral or state regulations may apply. In either case, the cyl-

inders shall not be charged and shipped if more than five

years have elapsed from the date of the last test date

stamped on the cylinder. The cylinders shall be retested

and restamped in accordance with DOT Code of Federal

Regulations (CFR) Title 49, Section 173.34.

5-5.3 Retest

DOT 4BA and 4BW cylinders used exclusively in FM-200

services that are commercially free from corroding compo-

nents are required to be hydrostatically retested and

restamped every five years, in accordance with DOT CFR

Title 4, Paragraph 173.37(e), prior to recharge and ship-

ment. An alternate option is an external visual inspection

performed in lieu of the hydrostatic test at the time the pe-

riodic retest becomes due (this option is in accordance with

CFR 49, Paragraph 173.34[e] [13]). Table 5-2 highlights

the two options for retesting FM-200 cylinders.

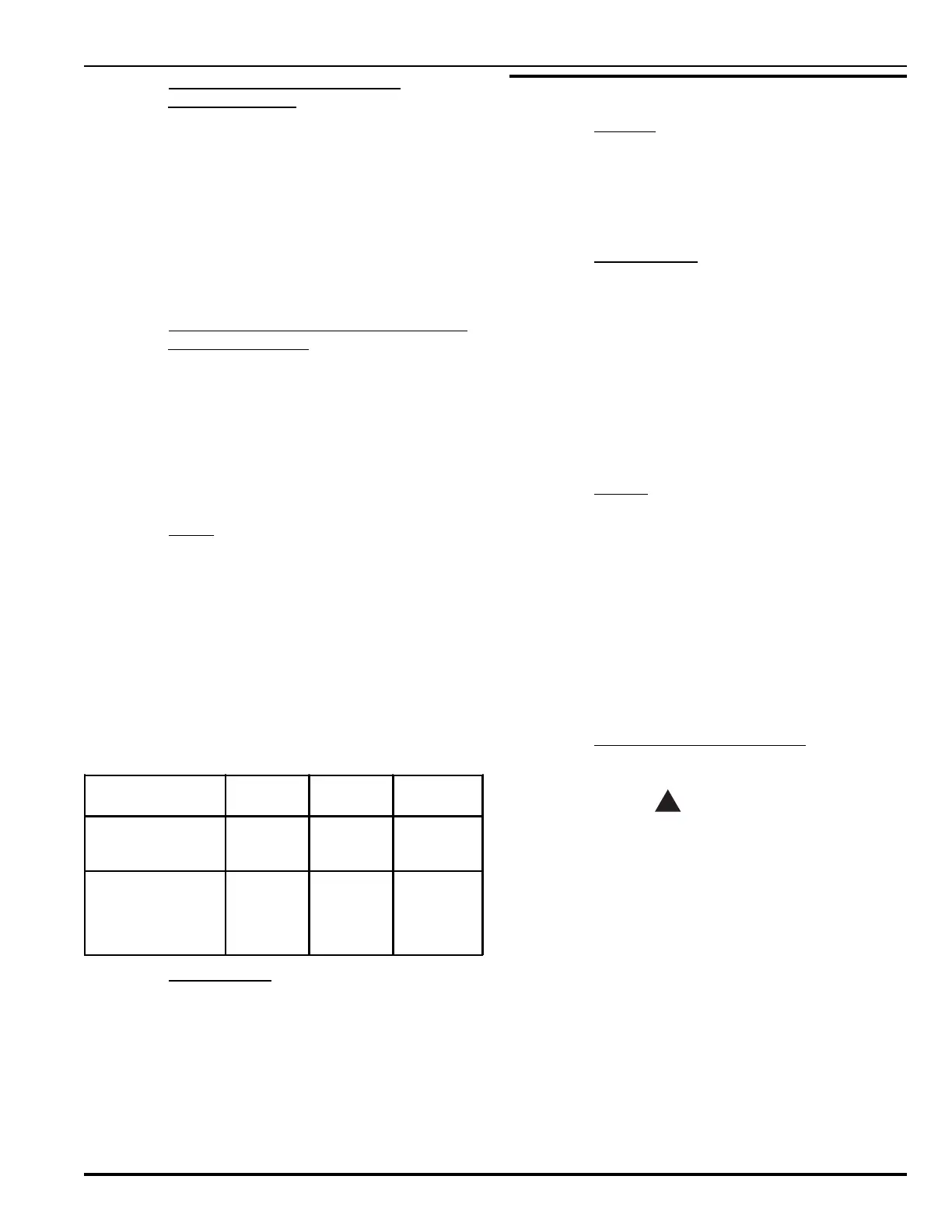

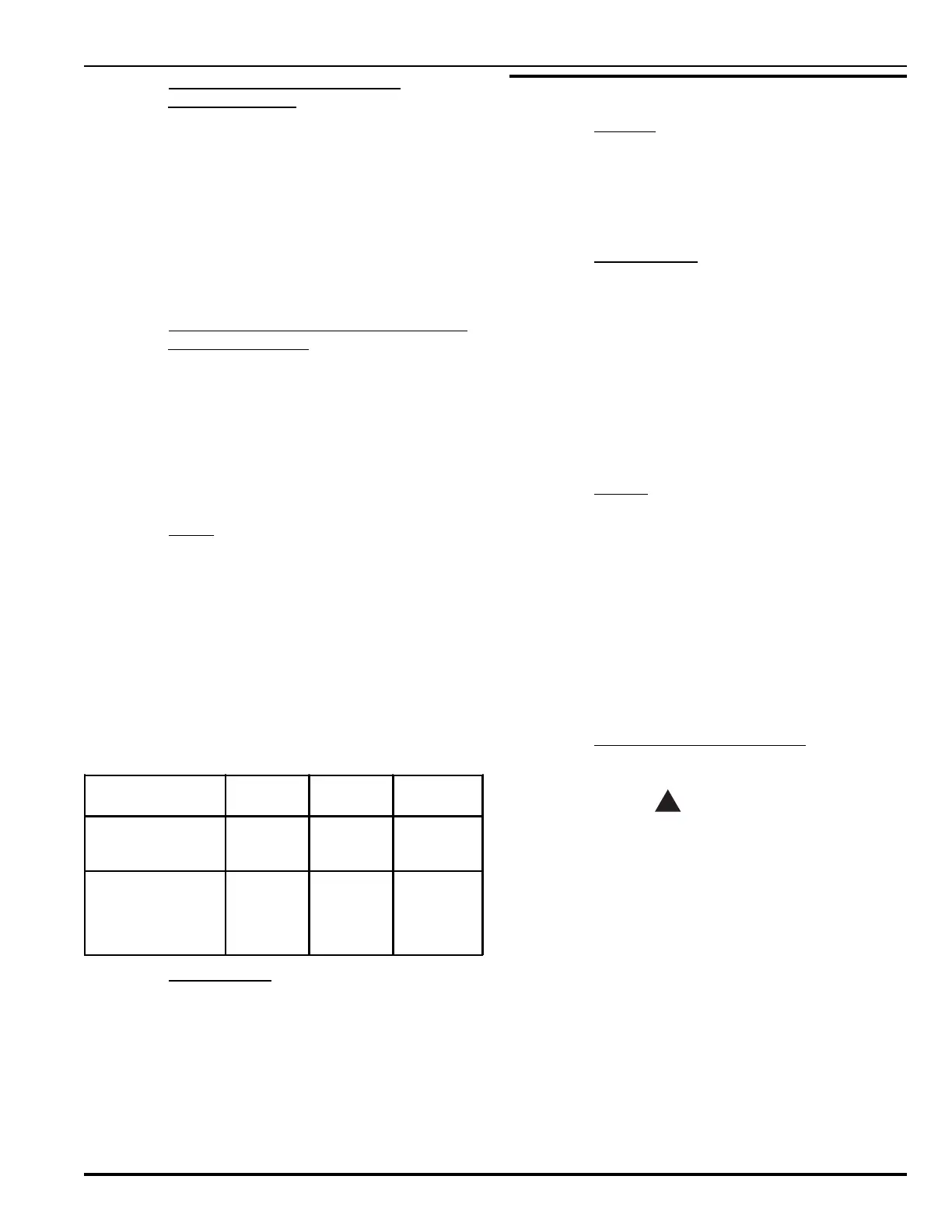

Table 5-2. Retest Schedule

Retest Method

First Retest

Due

Subsequent

Retest Due

Special

Marking

Full hydrostatic test

including determination

of cylinder expansion

5 years 5 years

Retest Date

Month/Year

External visual

inspection per

Paragraph 173.34(e)

(13) and CGA Pamphlet

C-6, Section 3

5 years 5 years

Retest Date

Followed by

"E"

5-5.4 Flexible Hoses

In accordance with NFPA 2001, all system hoses shall be

examined annually for damage. If the visual examination

shows any deficiencies, the hose shall be replaced or tested.

5-6 SERVICE

5-6.1 Cleaning

Remove dirt from metallic parts using a lint-free cloth

moistened with dry cleaning solvent. Dry parts with a

clean, dry, lint-free cloth, or air blow dry. Wipe non-me-

tallic parts with a clean, dry lint-free cloth. Remove cor-

rosion with a crocus cloth.

5-6.2 Nozzle Service

Service nozzles after use as follows:

1. Clean the outside of the nozzles with a rag or soft brush.

2. Examine the discharge orifices for damage or block-

age. If the nozzles appear to be obstructed, unscrew

the nozzles and clean by immersing them in clean-

ing solvent. Dry thoroughly with lint-free cloth. Re-

place damaged nozzles. Nozzles must be replaced

with the same part number in the same location. See

Paragraph 4-2.3.5 for the correct nozzle placement

and orientation.

5-6.3 Repairs

Replace all damaged parts found during inspection. Re-

placement procedures for FM-200 cylinders are provided

below. Since replacement for other system components are

similar, refer to the installation drawings and FM-200 sys-

tem assembly drawings for guidance.

FM-200 cylinders must be recharged when the cylinder

pressure gauge indicates the pressure is below normal (360

PSIG at 70°F [25 bar gauge at 21°C]), immediately after

discharge, when a loss in weight is in excess of 5% of the

original charged net weight or when there is a loss of pres-

sure (adjusted for temperature) of more than 10%.

5-7 Removing an FM-200 Cylinder

Remove an FM-200 cylinder as follows:

WARNING

!

Do not disconnect the flexible discharge hose

or valve outlet adapter prior to removing

pressure and electric control heads from the

FM-200 cylinders. Before replacing an FM-200

cylinder in a hazard area group, ensure that the

pilot line is completely vented of all pressure.

Loading...

Loading...