92

Chapter 2 Inspection

■

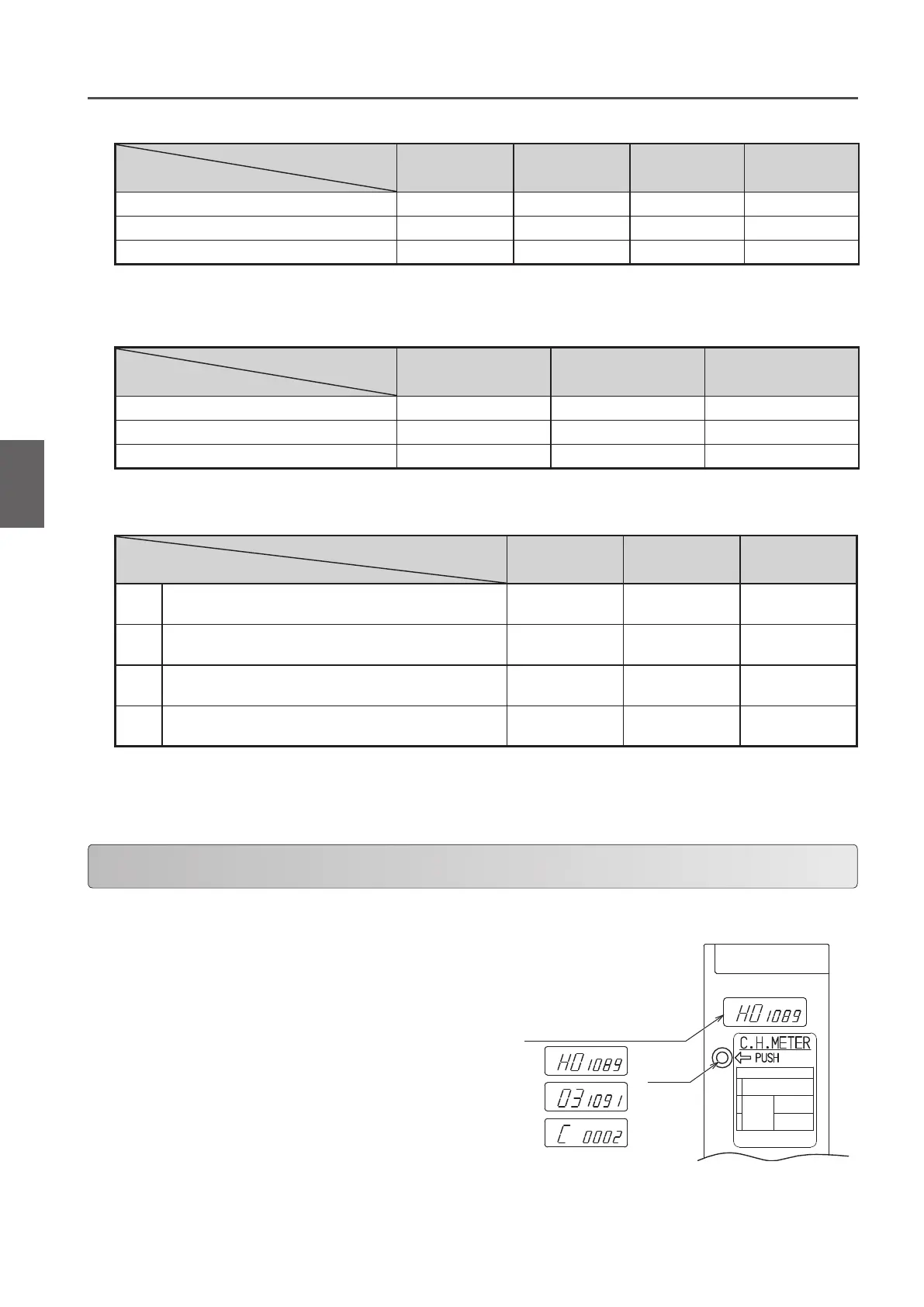

CH Meter: Start Times/Operating Hour Display Device

Contactor ON/OFF (lowering) times and operating hours

(motor energizing hours for lowering × 2) are displayed.

Use these values for control of operating condition and

maintenance at inspection and periodic inspection.

<How to use the CH Meter>

Open the controller cover and press the button at the side

of the terminal panel.

The display

①

,

②

and

③

appears in the LCD window in

the sequence and then disappears automatically.

①

Operating hours (1,089 hours in the right example)

③

+

②

Number of start (2,031,091 times in the right example)

NOTE) For the operating hours and the number of start of the dual speed VFD model, refer to the separate “VFD

Manual” to check the operating hours and the number of start.

Check of Operating Hours and Number of Start (CH Meter)

①

②

③

H

lower digits

upper digits

C

Number of

starts

-

Readout sequence

Hoist's on time in hour

Display on LCD window

Button

Periodic Inspection (continued)

■

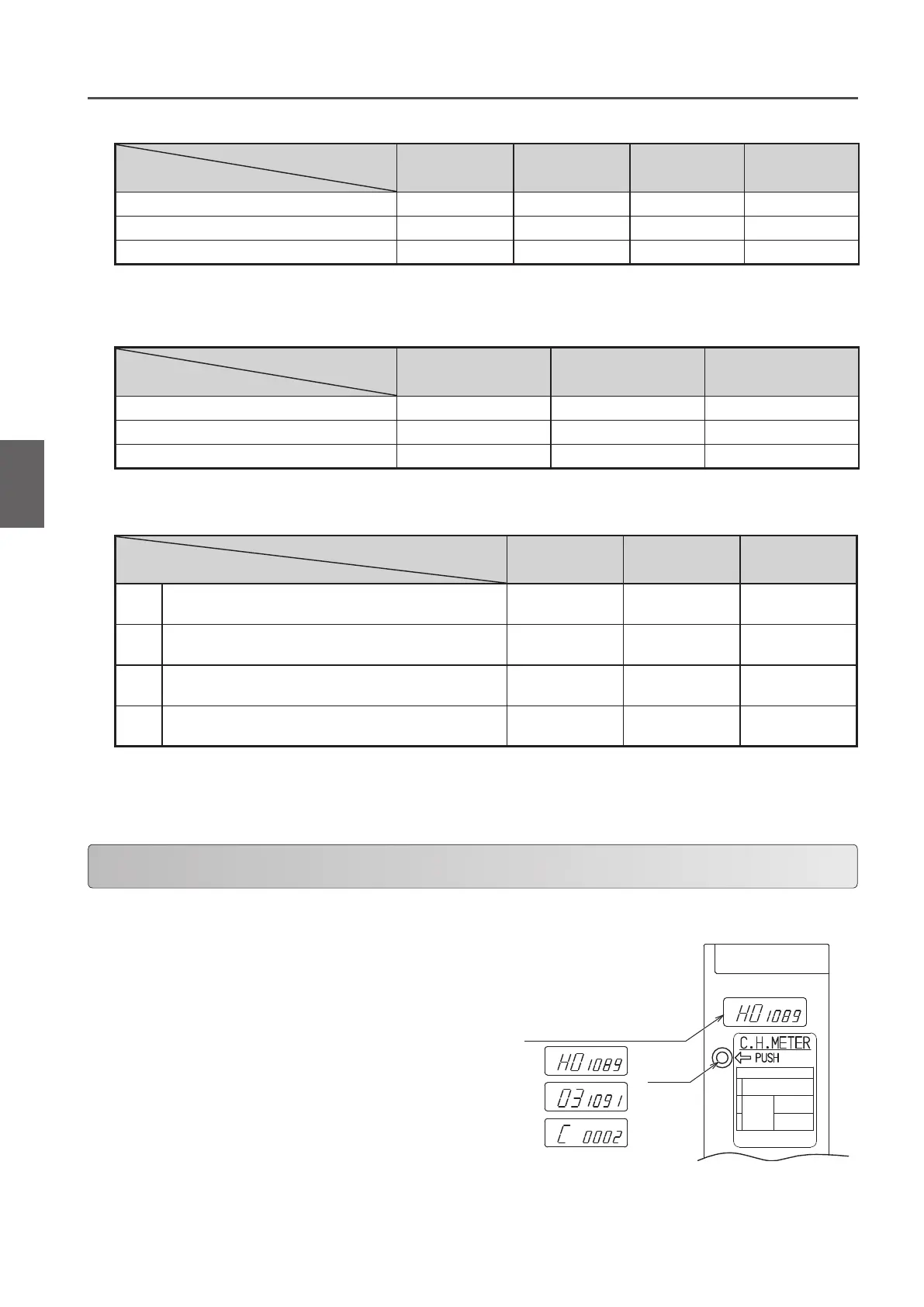

Guidelines on Bearing Replacement

Operating hours to replace parts

Body size grade

Every 800 hours Every 1600 hours Every 3200 hours

M6, 3m – – Parts replacement

M5, 2m – Parts replacement –

M4, 1Am Parts replacement – –

■

Guidelines on Hook and Yoke Replacement

Replace the Hook and Yoke in accordance with the rate of loading and the number of start in the following table.

Number of start to replace parts

Rate of loading

Every million

times

Every 1.5 million

times

Every 2 million

times

Light

A case where the capacity is rarely applied. Usually the hoist is

used with a light load.

○

Medium

A case where the capacity is applied considerably frequently.

Usually the hoist is used with a medium load.

○

Heavy

A case where the capacity is applied considerably frequently.

Usually the hoist is used with a heavy load.

○

Ultra

heavy

A case where the capacity is applied constantly.

○

■

Guidelines on V ring Inspection

Apply grease MOLITHERM No.2 on the V ring when the operating hours reaches at every 200 hours.

Refer to “Product Structure and Name of Each Part” (P122) for the location of the V ring.

Check of Operating Hours and Number of Start

2

■

Guidelines on Motor Shaft (with Rotor) Replacement

Operating hours to replace parts

Body size grade

Every 400 hours Every 800 hours

Every 1600

hours

Every 3200

hours

M6, 3m

– Apply grease on spline * – Parts replacement

M5, 2m

– Apply grease on spline Parts replacement –

M4, 1Am

Apply grease on spline Parts replacement – –

*Grease needs to be applied on spline part every 800, 1600 and 2400 hours.

Loading...

Loading...