TP-7070 7/1892 Section 3 Scheduled Maintenance

b. To check the fan belt tension using belt

deflection, use the following procedure:

(1) Measure the belt span (center line of pulley

#1 to center line of pulley #2).

(2) Use the measurement to determine the

middle of the belt.

(3) Press on the V--Belt at the middle point and

measure the deflection from its original

position.

(4) For the maximum deflection, refer to

Figure 3-19.

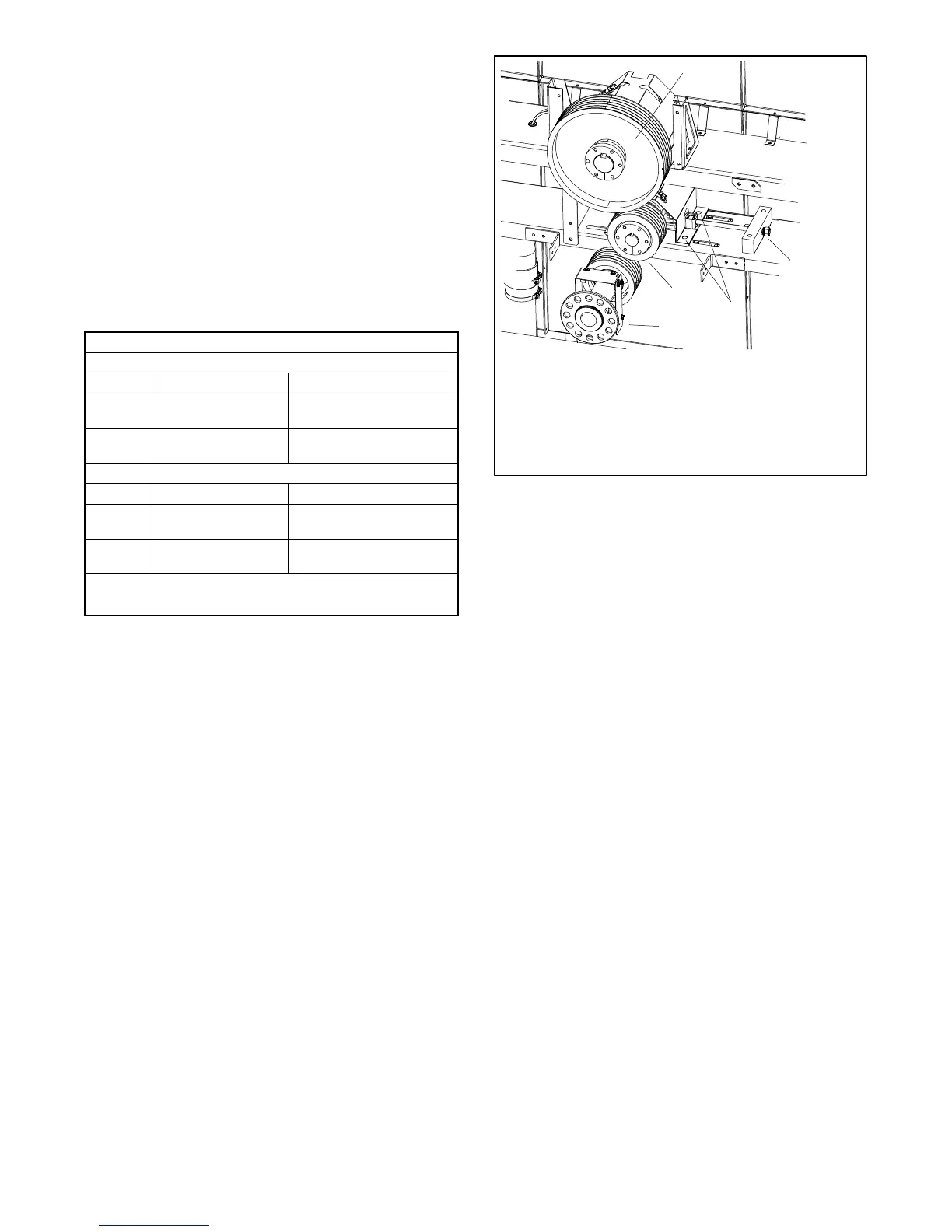

Engine to Fan Sheave (Driver to Driver)

KD2000 to KD2500

Frequency (Hz) Deflection

New Belt 78.4--81.2 81--86 N @ 9 mm

(18--19 lbs @ 0.4 in.)

Used

Belt

72.6--75.6 70--75 N @ 9 mm

(16--17 lbs. @ 0.4 in.)

KD2800 to KD3250

Frequency (Hz) Deflection

New Belt 62.7--64.9 89--95 N @ 12 mm

(20--21 lbs @ 0.5 in.)

Used

Belt

58.1–60.5 77--83 N @ 12 mm

(17--19 lbs. @ 0.5 in.)

Note: Tension chart is only applicable for models

KD2000--KD3250.

Figure 3-19 Belt Tension and Deflection

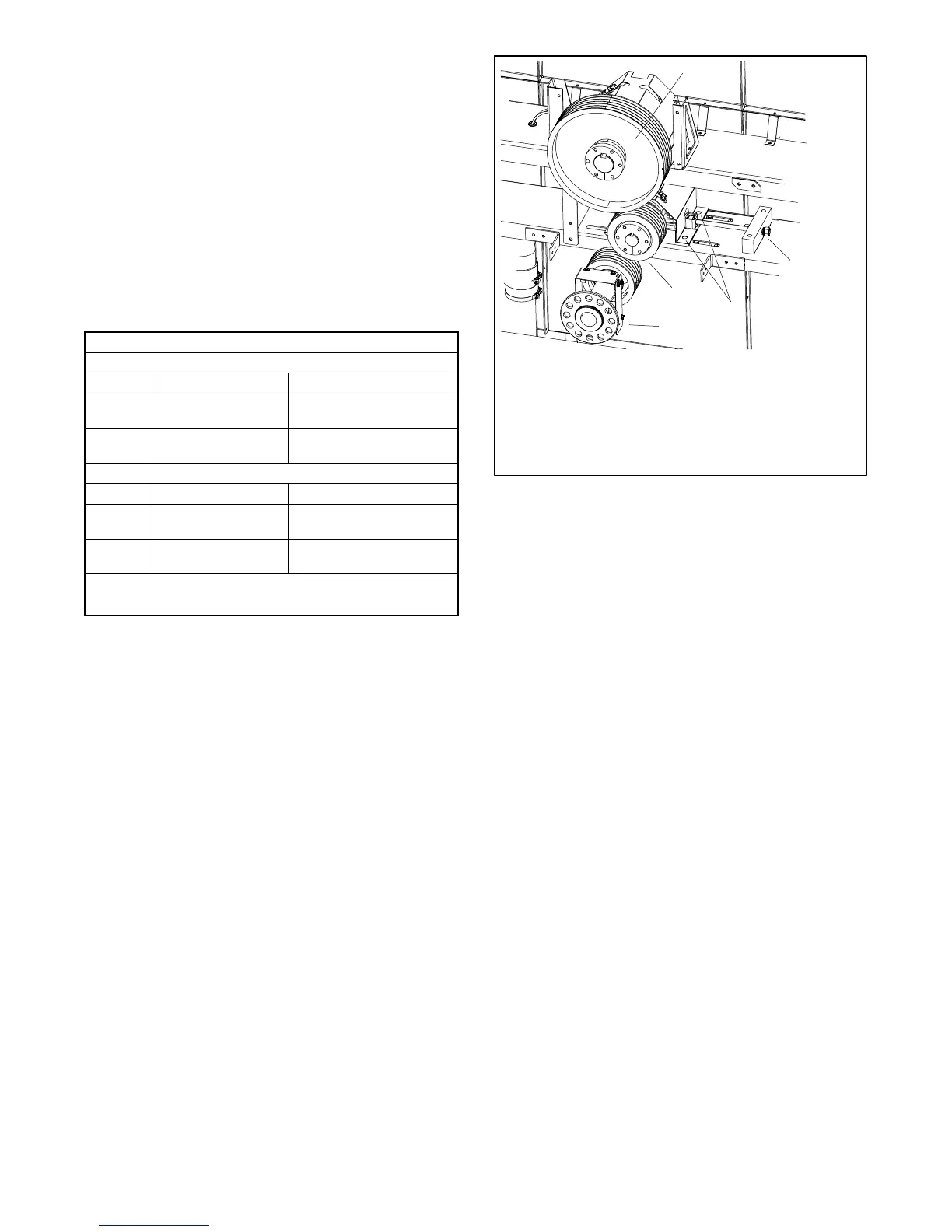

5. Before making adjustments to the tension, loosen

the four 3/4” undercarriage bolts. Then, adjust the

tensioner pulley along the tensioner slots via the

lead screw. See Figure 3-20.

1. Fan pulley

2. 3/4” undercarriage bolt locations

3. Lead screw

4. Tensioner pulley

5. Engine pulley

10301001101

2

3

1

4

5

Figure 3-20 Tension Adjustment, KD2000--KD3250

6. Make the necessary adjustments until belt tension

falls into the range listed in Figure 3-19.

7. Check the pulley alignment on the fan shaft for

angularity.

8. Adjust the fan sheaves and tensioner sheaves to

eliminate or reduce the pulley angularity.

9. Tighten the 3/4” undercarriage bolts.

10. Reinstall the belt guards using the original

hardware.

11. Reconnect the generator set engine starting

battery(ies), negative (--) lead last and return the

generator set to service.

12. Test run the generator set for a few minutes and

listen for belt noise (squeal) indicating a slipping

belt. Stop the generator set.

If the belt slips after the belt tension procedure, clean the

pulley surfaces and repeat the belt tension procedure. If

slippage continues, replace the fan belt.

Loading...

Loading...