OPERATING MANUAL

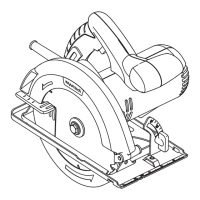

Compact Circular Saw

241-9853

IMPORTANT:

Carefully read this Owner’s Manual before using this tool. Pay close atten-

tion to all Safety Instructions, Warnings, and Caution sections. Use this tool

properly, and only for its intended use

.

Safety symbols in this Manual are used to flag possible dangers. The safety

symbols and their explanations require the operator’s full understanding. The

safety warnings do not, by themselves, eliminate any danger, and they are not a

substitute for proper accident prevention measures.

This Safety Alert Symbol indicates caution, warning, or danger. Failure to obey

a safety warning can result in serious injury to yourself or others. To reduce the risk

of injury, fire, or electric shock, always follow the safety precautions.