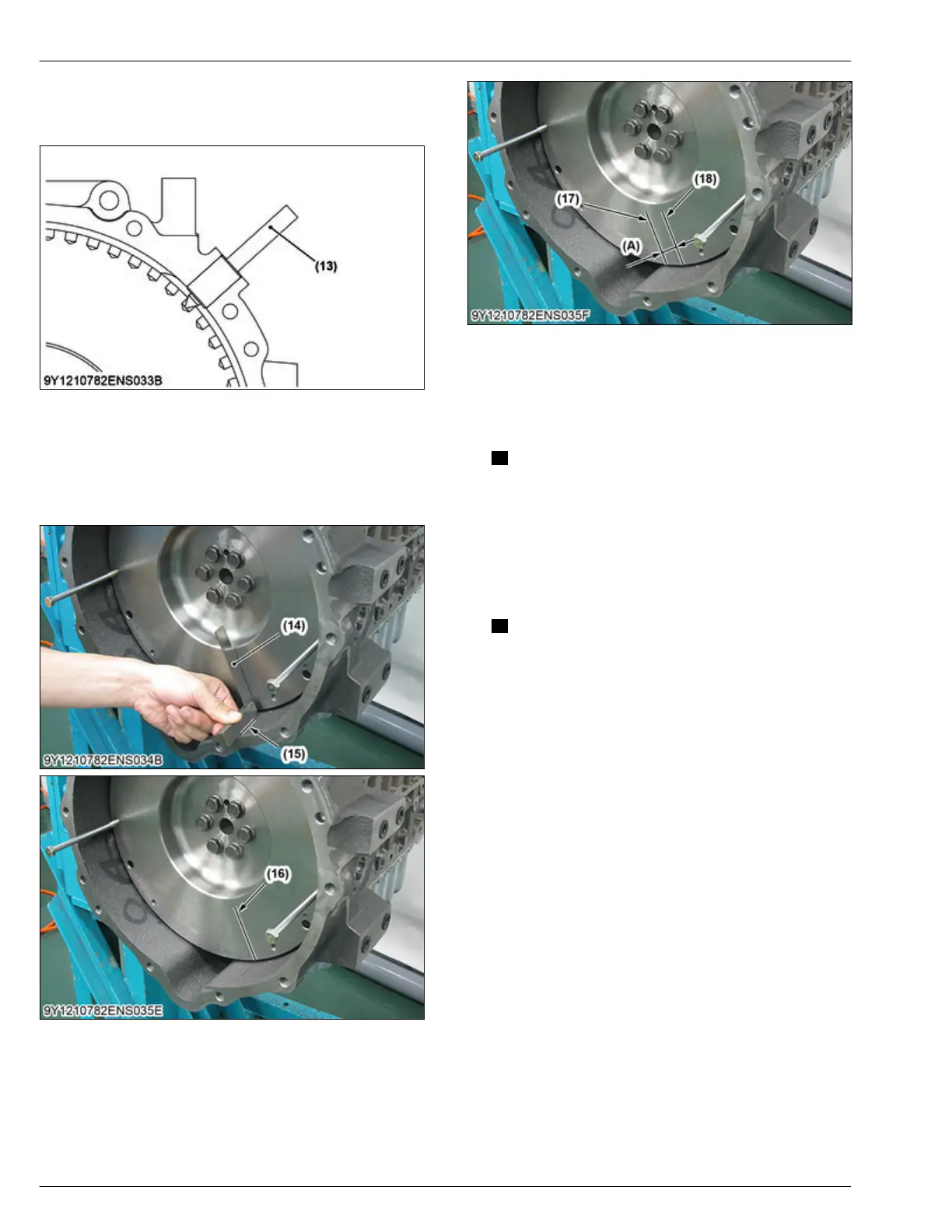

11. Insert

a special tool that injection top correction jig

(13)

into the crankshaft position sensor mounting

hole and align the center of handle and pulsar.

(13) Injection top correction jig

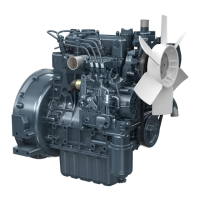

12. This position is the crank position sensor top dead

center

detection position so position the tri-square

(14) on the reference line (15) set in the previous

item and make a crank position sensor top dead

center detection position mark (16) on the flywheel.

(14) Tri-square

(15) Reference line

(16)

Mark of crankshaft position

sensor top dead center de-

tection position

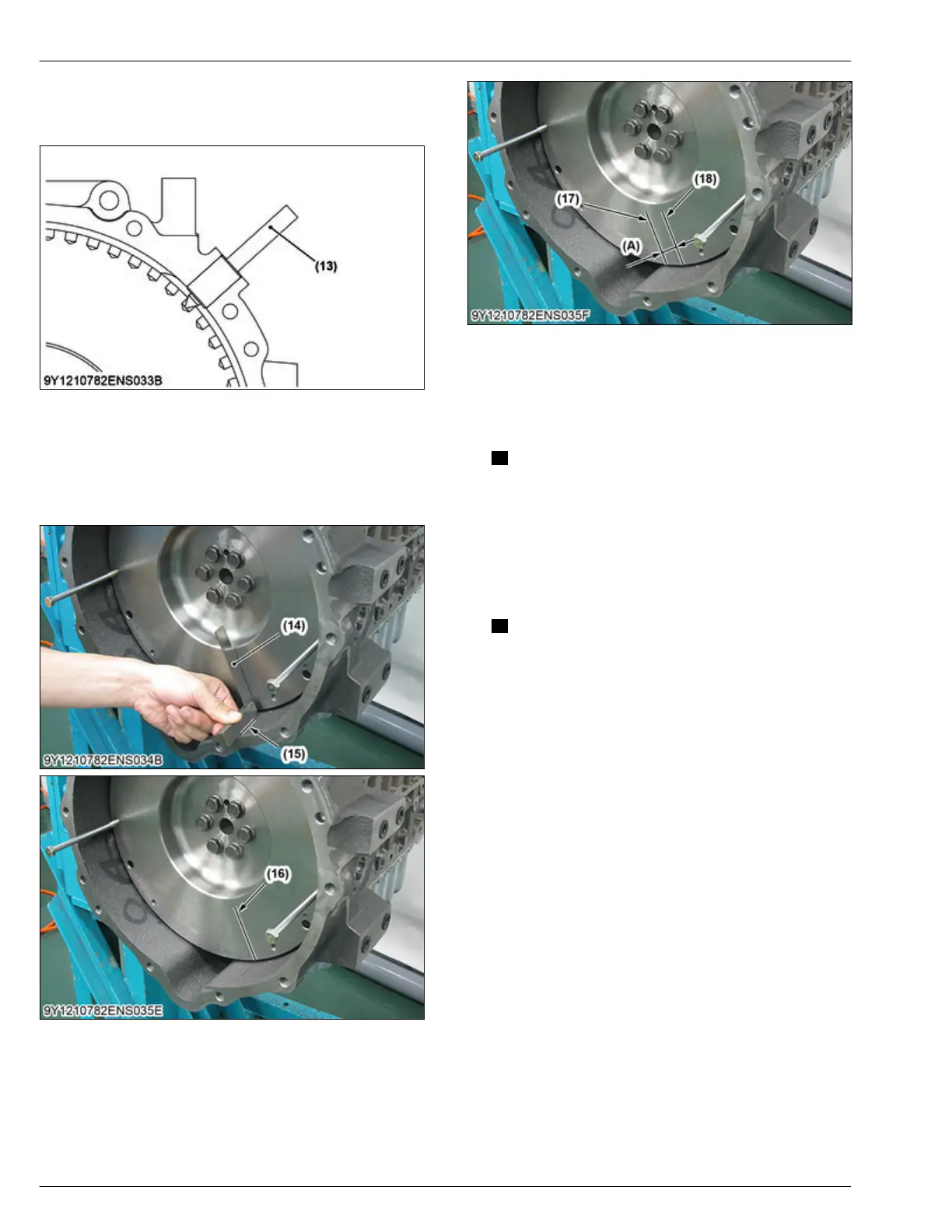

13. Measure

the

difference (A) between the top dead

center mark (17) and the crankshaft position sensor

top dead center detection position mark (18).

(17) Mark for top dead center

(18) Mark of crankshaft position

sensor top dead center de-

tection position

(A)

Difference (mm)

14. Calculate the

fuel injection timing correction by

difference (A).

IMPORTANT

• 1 mm = 360° / (Flywheel Diameter × π)

•

If the crankshaft position sensor top dead

center detection position is in front of top

dead center, enter a negative value.

If the crankshaft position sensor top dead

center detection position is in back of top

dead center, enter a positive value.

NOTE

• Corrected

angle

= (360 / (flywheel diameter ×

π)) × difference (A)

15. Overwrite the injection timing correction value in the

engine ECU.

4.31 Adjusting air gap between

crankshaft position sensor and

flywheel

Tools required

• V

ernier caliper

• Depth gauge

1. Measure the

crankshaft position sensor length

between the sensor tip and sensor flange (1) face

with vernier caliper.

2. Measure the depth from sensor attaching face of

flywheel housing to flywheel side (2) surface with

depth gauge.

4. ENGINE

SERVICING

4. Checking and adjusting

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...