9

8. Connection for automatic welding

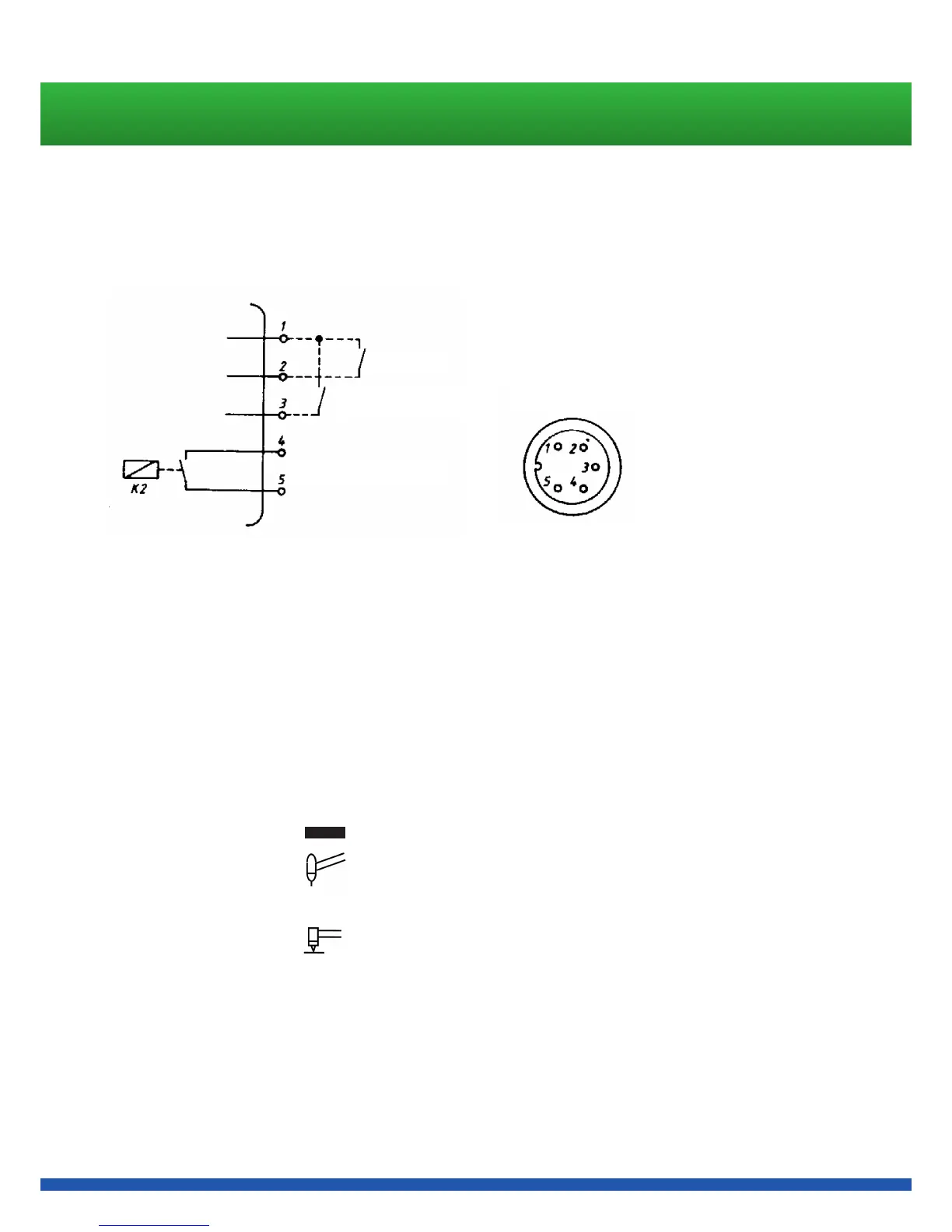

With socket b the machine can be connected to an automatic control (see wiring diagram)

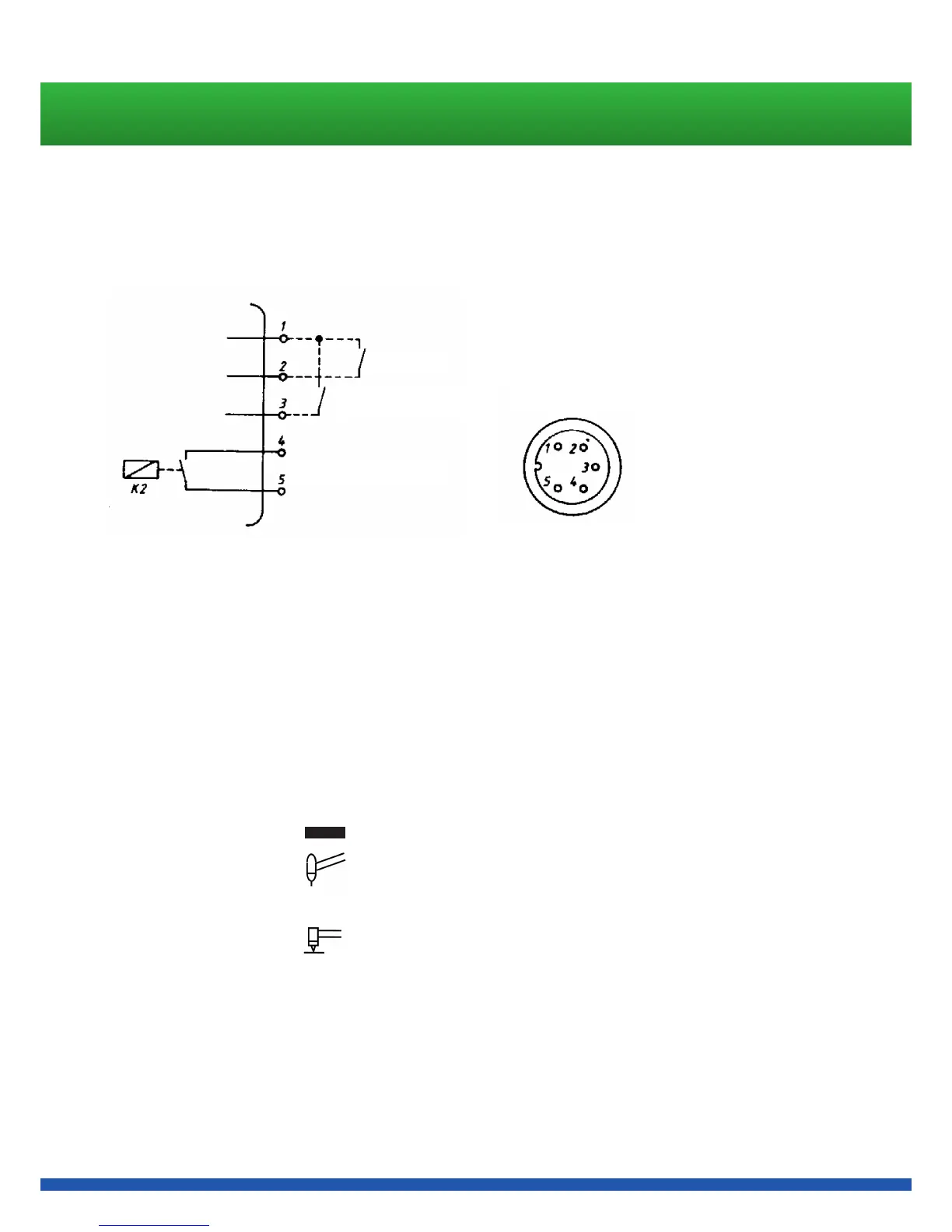

Wiring diagram of 5-pole socket on adjusting board

* When switching on the pilot arc about the contacts 1 and 3 of the socket b the switch f remains

into mid position.

Starting up

A. Plasma Welding

1. Open cylinder valves and handwheels for gas flow rate at regulators.

2. Switch main switch F on. Fan and water pump will start, lamp d will light.

3. Keep torch away from work

4. Set switch i to symbol

5. set switch k to symbol

6. Push test button for plasma gas and adjust flow rate acc. to data sheet plasma welding

7. set switch f to symbol (Pilot arc will ignite after a gas pre-flow time of about 5 sec. and

lamp e will light up.

8. Keep button E depressed and adjust welding current. Amperage is preset at potentiometer a

and can be read from ammeter D.

9. Actuate torch switch or foot switch and adjust flow rate of shielding gas at the other regulator.

10. Adjust gas post-flow time on potentiometer l

Installation

Start

Pilot extern on*

View of the front

Current relais

Loading...

Loading...