69

C

C

H

H

A

A

P

P

T

T

E

E

R

R

8

8

T

T

R

R

O

O

U

U

B

B

L

L

E

E

S

S

H

H

O

O

O

O

T

T

I

I

N

N

G

G

A

A

N

N

D

D

S

S

E

E

R

R

V

V

I

I

C

C

E

E

R

R

O

O

P

P

E

E

R

R

A

A

T

T

I

I

N

N

G

G

L

L

O

O

G

G

Refer to the following table if your filtered enclosure fails to

operate properly. If the suggested corrective actions do not solve

your problem, contact Labconco for additional assistance.

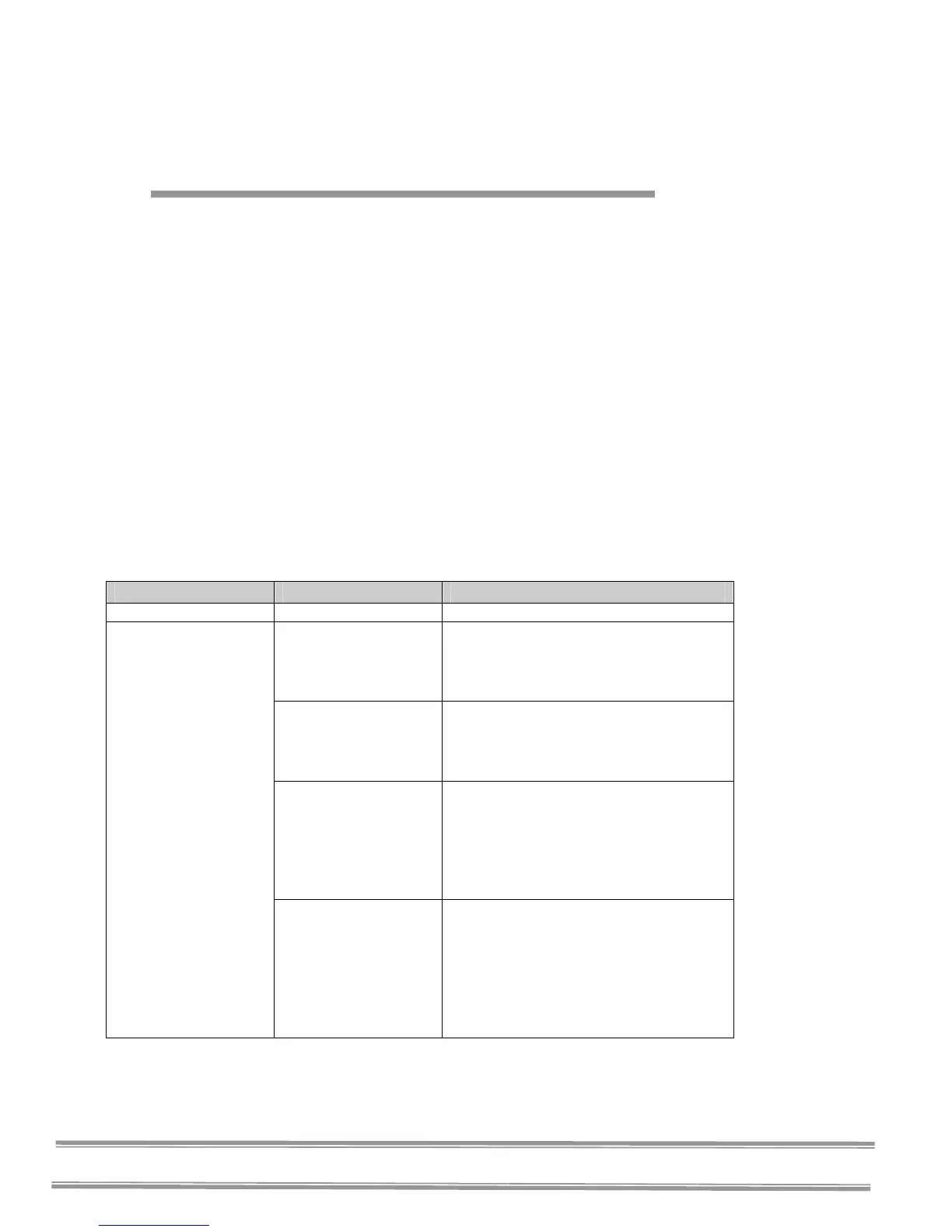

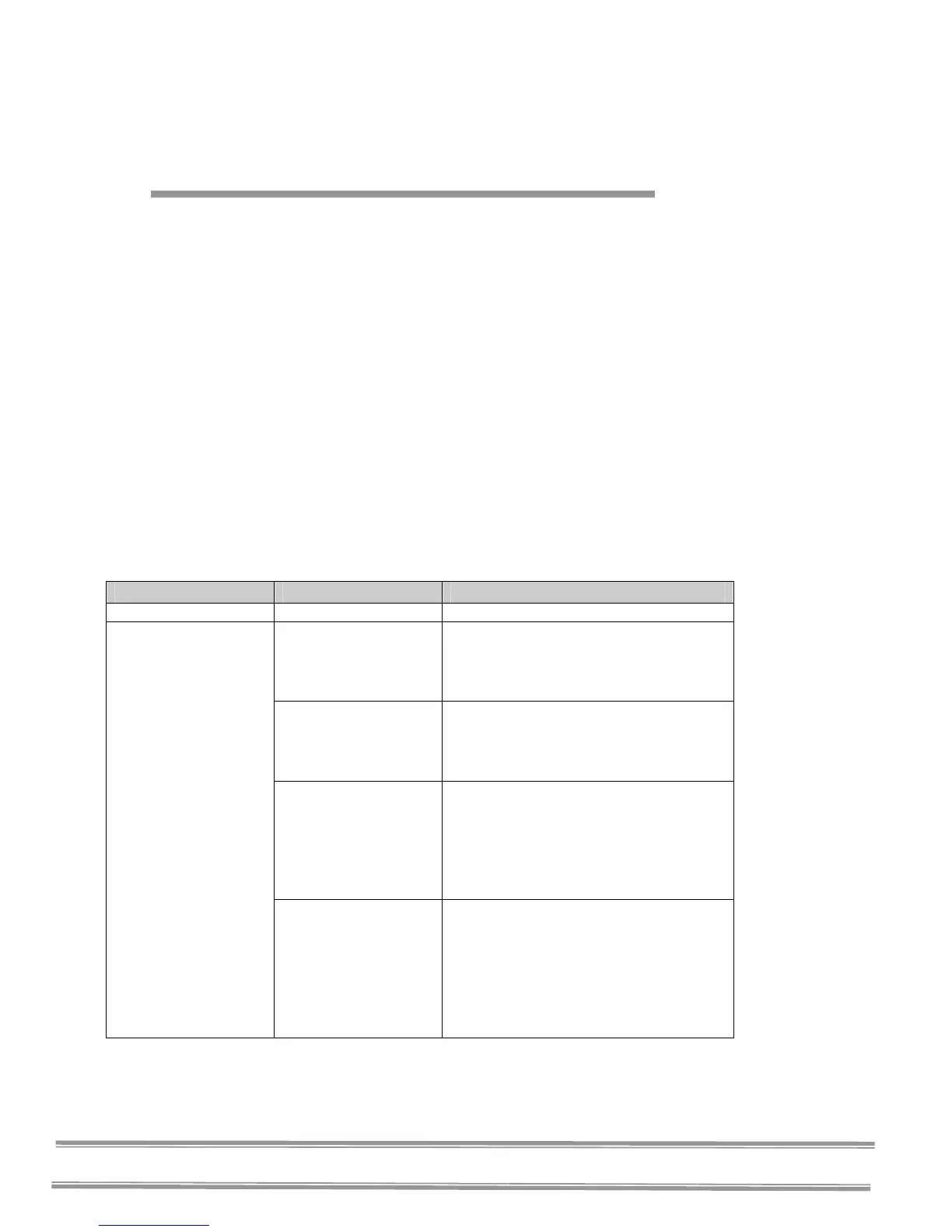

PROBLEM CAUSE CORRECTIVE ACTION

Contaminants outside

of enclosure.

Improper user

techniques for the

enclosure.

See “Certifying the Enclosure” Chapter

3 and “Safety Precautions” Chapter 4

sections in the manual. (Ref. Appendix

D).

Restriction of the

baffle air slots or

blockage of the

exhaust outlet.

Remove obstruction to ensure that all

air slots and the exhaust outlet are

unobstructed.

External factors are

disrupting the

enclosure airflow

patterns or acting as a

source of

contamination.

See “Location Requirements” Chapter

2, “Certifying the Enclosure” Chapter

3, and “Safety Precautions” Chapter 4

sections of this manual. (Ref. Appendix

D).

Enclosure has

improper face

velocity.

Have enclosure certified and check

exhaust system. Check HEPA filters for

loading. Adjust enclosure speed

control. Enclosure should have an

average face velocity of 60-100 fpm for

weighing procedures and 75-105 fpm

for biohazardous procedures.

Loading...

Loading...