EN

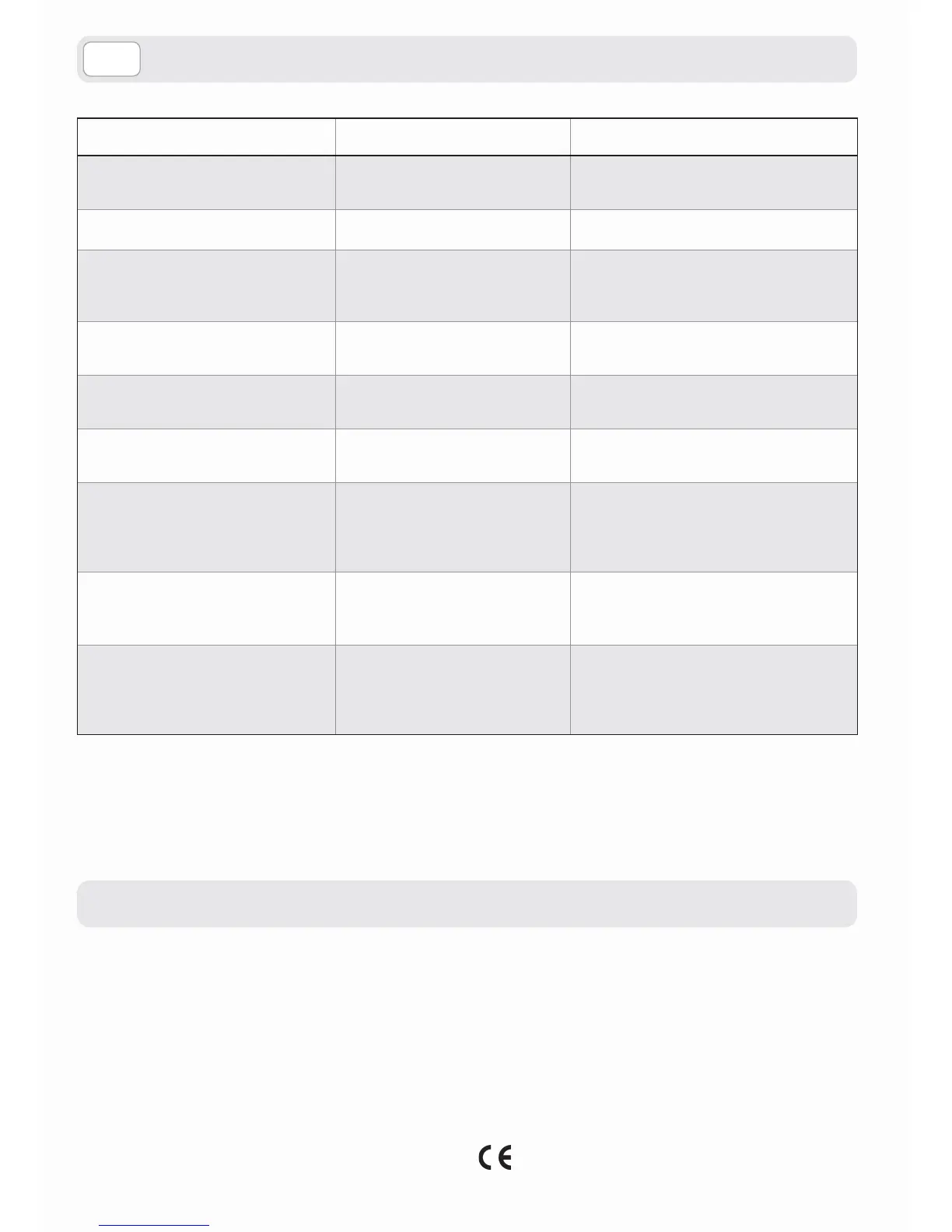

TROUBLESHOOTING

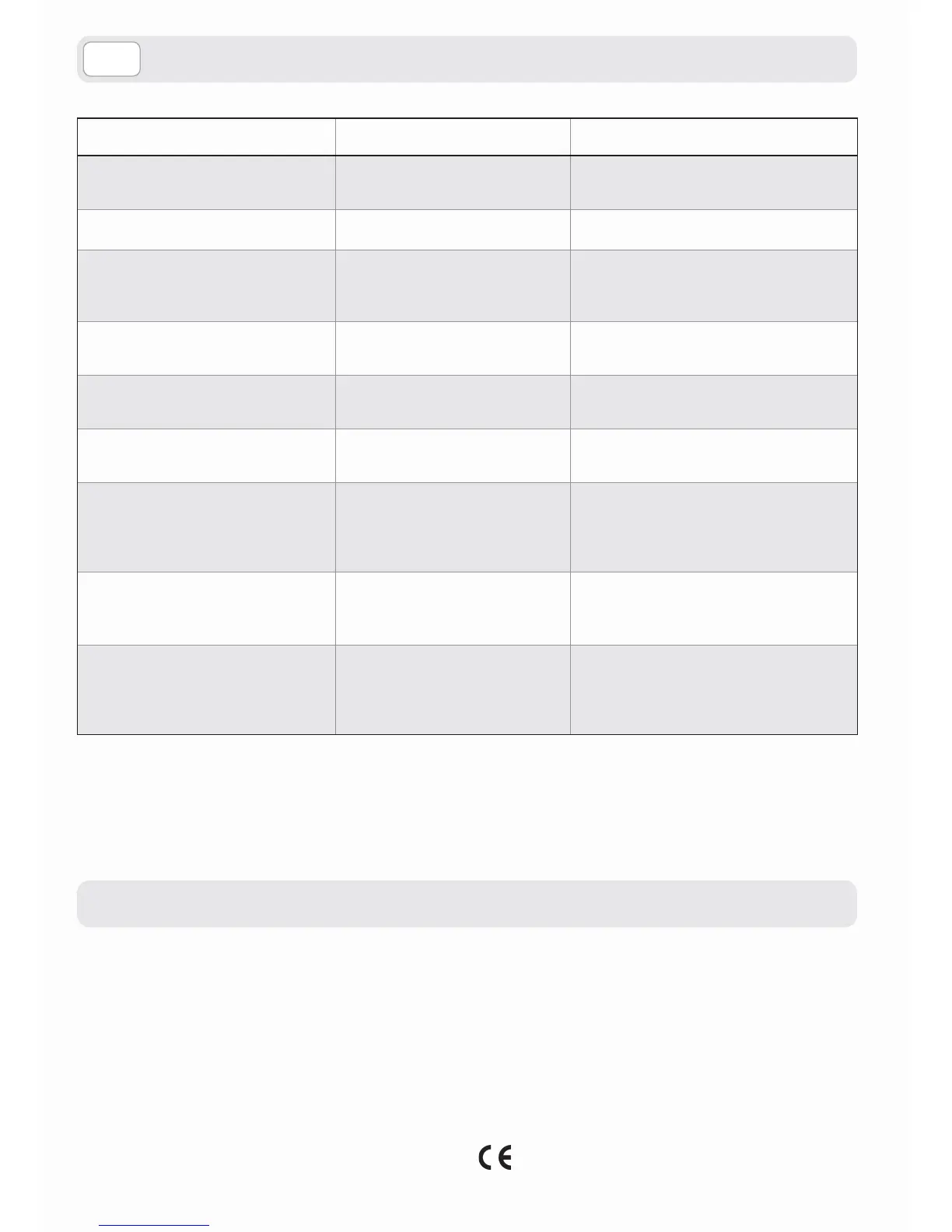

TECHNICAL SPECIFICATIONS

Problem encountered Possible causes Solution

The machine does not turn on. » The machine is not connected to the electric

network.

» Connect the machine to the electric network.

» Contact after-sales service.

The machine requires a lot of time to heat up.

» The appliance is full of limescale. » Descale the machine.

The pump is very noisy.

» No water in the tank.

» The tank has been lled without priming the

water circuit.

» Re ll with fresh drinking water.

» Carry out the priming of the water circuit (see section

“Priming the water circuit”).

It is not possible to insert the pod holder

» Pod holder in the wrong position.

» Pod inserted incorrectly.

» Change the pod holder position.

» Remove the pod and place it again.

The co ee is cold.

» The indicator light was o when the co ee

brew button was pressed.

» Wait until the indicator light turns on.

The co ee is brewed too fast; the brewed co ee

is not creamy.

» Pod already used. » Remove the pod holder and place a new pod.

Co ee is not brewed or brewed in drips only.

» Clogged pod holder.

» The water circuit is empty.

» Carry out the dispensing spout wash cycle (see

MAINTENANCE AND CLEANING).

» Carry out the priming of the water circuit (see Section

“Circuit Priming”).

Hot water/steam not dispensed.

» Clogged steam wand. » Clean the spout with a needle (the machine needs to be

unplugged and the steam/hot water dispensing knob

needs to be closed).

The milk does not froth.

» Not suitable milk.

» The milk is too hot.

» The indicator light was not steady on.

» Use fresh, partially skimmed milk.

» Use milk at refrigerator temperature.

» Press the steam button and wait for the indicator light

to turn on.

· Nominal Voltage - Power Rating - Power Supply:

See label on the appliance

· Size: Height Width Depth

318 mm 187 mm 276 mm

· Weight: about 5 kg

· Water tank: about 1.4 litres - Removable

· Materials used for the chassis: Thermoplastic material

· Power cord length 1.2 m

· Control panel: On the upper part

· Boiler: Aluminium

· Safety devices: Pressure safety valve.

· Double thermal fuse

Please contact a Saeco service centre for any faults not covered in the above table or when the suggested solutions do not solve the problem.

2006/42 EC - 2004/108 EC - 2006/95 EC

Loading...

Loading...