PRIMERS

AnybrandofprimermaybeusedWhenus

ingfinegrainedballpowderit’sbest touse

aprimerwithacoveredflashholetoprevent

thepowderfromenteringtheprimerThisis

notdangerousbutmayuponfiringleakgas

aroundtheprimerItcoulddrivethecaseinto

the chamber and disable the gun until the

shellisremovedwithacleaningrod

CAUTION To reduce the chance of mass

detonation of primers in the primer feed, use

only primers that have a covered flash hole.

POWDER

Afterdeterminingtheamountofshotyoude

siretouseselectthepowdertypeandproper

powder and shot bushing from the charge

tableLoads listedonthecharge table have

beencompiledfromloaddatasuppliedbythe

powdermanufacturersIthasbeencondensed

toasimplifiedformforusewithyourLoad

AllIIOnlyloadsthatproduceuniformresults

withavarietyofcomponentsarelisted

CASES

Your Lee LoadAll II will load all types of

cases with ease However cases made for

trap and skeet shooting are designed for

reloadingand willreloadmore timesbefore

wearingoutCaseswithsplitendscrackedor

damagedbrassandholesburnedintheside

shouldbe discardedHigh brasscaseorlow

brasscaserefersonlytothebrasslengthon

the outside of the case This doesnot have

anybearingonthestrengthofthecaseorthe

loadit willaccept Thebrasslength isonly

a selling feature designed to impress the

purchaserwiththeimpliedextrapowderThe

importantconsiderationin caseselection is

thetypeofbasewadCaseswithapaperbase

wadrequireslightlymorepowderforthesame

velocityLesspowdermust beusedincases

withplasticbasewadornobasewadsuchas

RemingtonRXPWinchesterAAWinchester

Compression Formed or Federal Champion

IIBesureyoucanselectyourloaddatafrom

thepropercolumnonthechargetable

SHOT

All of the current manufacturers of shot

supplygoodqualityshotSelectionbylowest

priceissuggested

WADS

Your Lee LoadAll II is designed to load

plastic wads only preferably the one piece

varietyWhenusing thesenowadpressure

is required and if applied will quickly

neutralizeitselfCrimpingtheshellinreality

appliesthewadpressureTheimportantand

basicdierence in theonepiecewad is the

lengthofthewadandtheamountofspaceit

occupieswithintheshellItisimportantthat

theshellbecompletelyfilledtomakeagood

crimp Once the weightof shot is selected

the only variable volume component is the

wadThisinformationissuppliedbythewad

manufacturerusuallyprinted onthebag or

cartontheyarepackagedinThecorrectwads

fortrapandskeetloadsarereadilyavailable

becausetheyarethecasesmostoftenloaded

Wad types are usually listed on load data

suppliedbypowdermanufacturersSeeyour

localsportinggoodsdealerorwrite directly

tothepowdermanufacturerforacopyofthe

latestloaddata

Generally wads will come in two basic

lengths long and short A supply of each

size will take care of of your loading

Sometimes it may be necessary to slip a

cardboard wad of a smaller gauge to take

up excess space Flake type powder will

compress more than the ball or granular

powderChangingpowdertypemaymakea

dierenceinthefinalcrimp

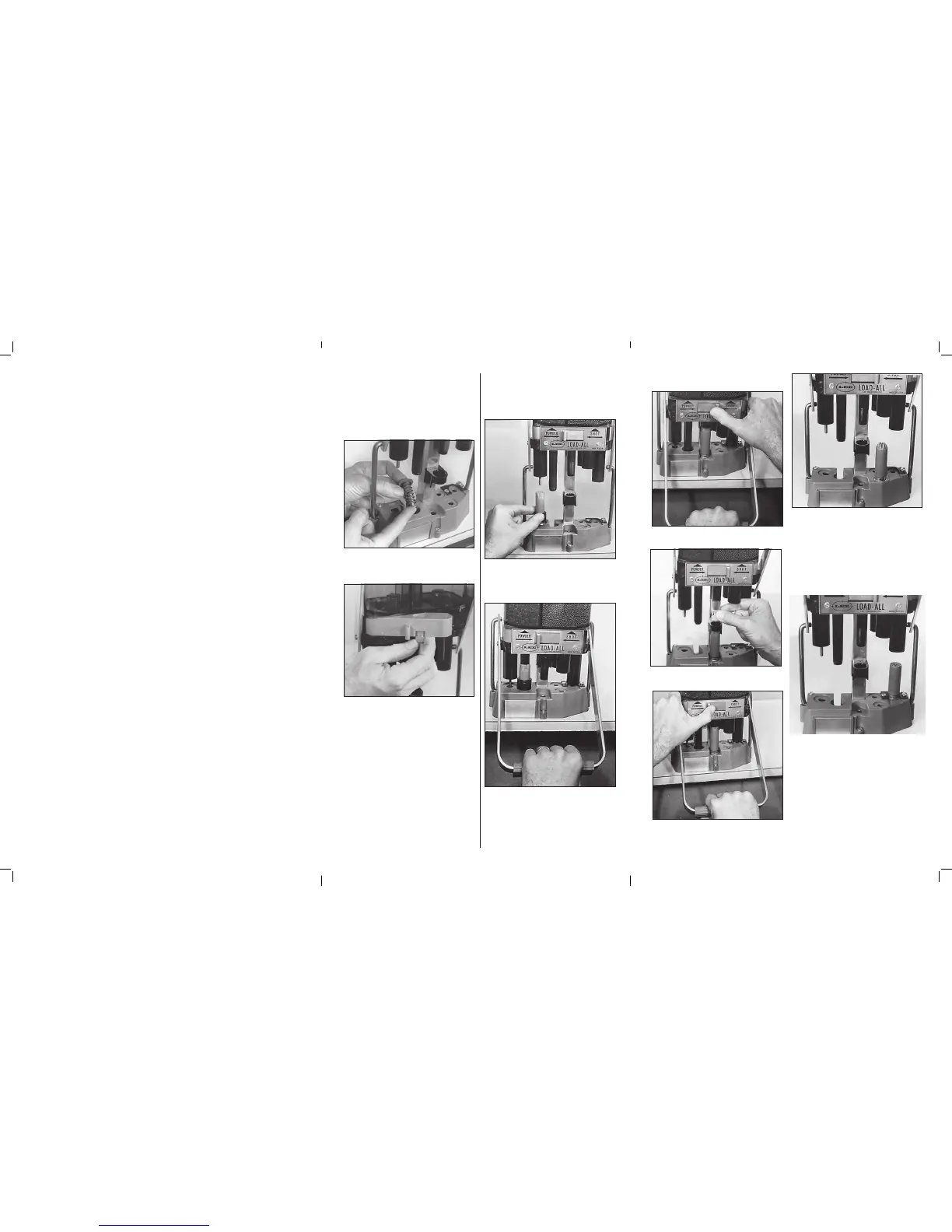

STATION 3 Slip the shell into the wad

guide at STATION 3.

STATION 3a

Lower the handle and slide

charge bar to the right. This adds the powder.

STATION 3b Raise handle, insert proper

wad and lower the handle until it stops.

STATION 3c Slide the charge bar to the

left to add the shot. Raise the handle.

STATION 4 Place the shell under the

proper crimp starter. Keep an inward fold of

the shell mouth toward the front for proper

alignment with the segmented starter. De-

press the handle to a full stop. Some shells

may require a two-second pause to set the

plastic.

Note The 8-segment crimp starter is in

the front on the 12 GAUGE only. The other

gauges have the 6-segment starter in the

front. Be sure you select the correct one.

STATION 5 Immediately move the shell

into the shell holder at STATION 5 and com-

plete the crimp. You should have a perfectly

crimped shell with a nice, tapered end.

IMPORTANT A good crimp can only be

obtained if the wad is the correct length.

After the shot is added, there should be

about

⁄ inch of shell above the shot on a

12 gauge; about

⁄ inch for the 20 gauge;

and just slightly more for the 16 gauge. If

the crimp is too deep with a hole in the cen-

ter, use a longer wad. Mashed in crimps or

crushed cases indicate the wad should be

shorter.

BEFORE YOU START

RELOADING

1

Mount your Lee Load All II to a sturdy

bench or table with the three screws

supplied. See

HELPFUL HINTS

for por-

table mounting.

Mount press no more than ½” from edge of

bench for handle clearance.

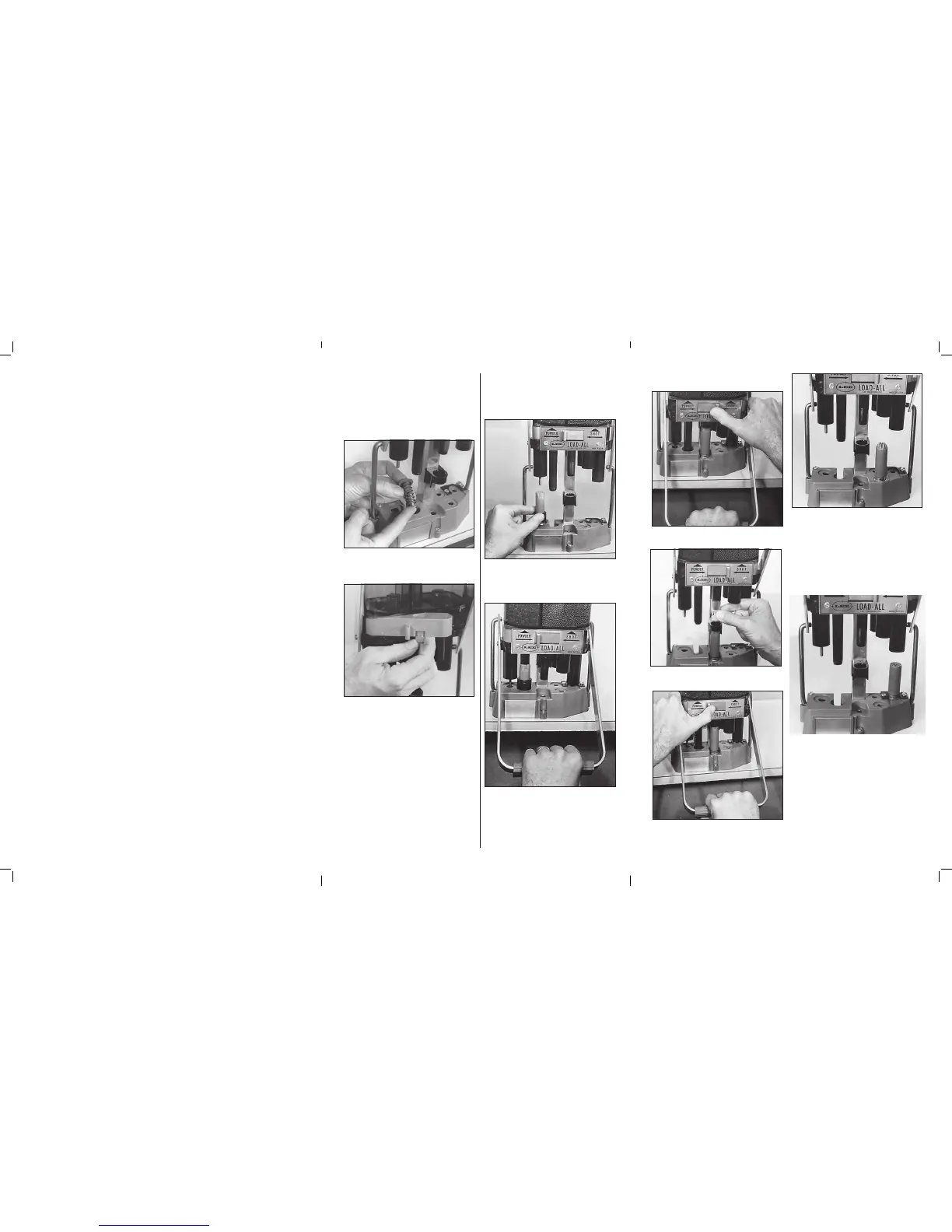

2

Install the primer punch, spring and

primer guide into

STATION 2.

3

Remove two screws holding the

nameplate. Remove charge bar and

install correct shot bushing and

powder bushing as shown on the

charge table. Reassemble, being

careful to not overtighten the screws

.

CAUTION Recheck the bushing against

the load data. Too much shot or powder will

cause dangerous pressures.

4

Slide the charge bar to the left and fill

the shot and powder hoppers. Note the

powder hopper is the smaller one on

the left, above the word

POWDER on the

nameplate

.

5

Sort cases as to brand and type and

discard the defective ones. Because in-

terior length differs between brands and

types, they require different length wads.

It’s best to load one type at a time

.

NOW YOU CAN

BEGIN RELOADING

Your Lee Load-All II is factory set

and requires no adjustment.

STATION 1 Slip the sizing die,

grooved end up, over the shell. Place

the shell in STATION 1 and pull down

the handle. This will full length size and

deprime the shell.

STATION 2 Place a primer in the

priming pocket at STATION 2. Move the

shell onto STATION 2; pull down the

handle. The sizing die will automatically

be pushed off at this station. Remove it

completely from the shell.

CONVERTING TO ANOTHER GAUGE

The Lee LoadAll II is easily and economically

convertedtoanothergauge

12 GAUGE Order 90070

16 GAUGE Order 90071

20 GAUGE Order 90072

DISASSEMBLY AND CONVERSION

Springthealuminumhandlefreeofthepivot

pins and slide the hopper assembly o the

squarecolumnHoldyourhandoverthepow

derhopperwhileemptyingtheshotPourthe

powderbackintoitsoriginalcontainer

Removethenameplateandhopperandinstall

ontothenewcarrier

Replacethe wadguideand gaugeuse

thesamewadguide

Replacetheshellholder

Reassembletothecolumnandhandle

Be sure to install the correct shot and

powderbushings

Loading...

Loading...