# 45464K003 Page 17

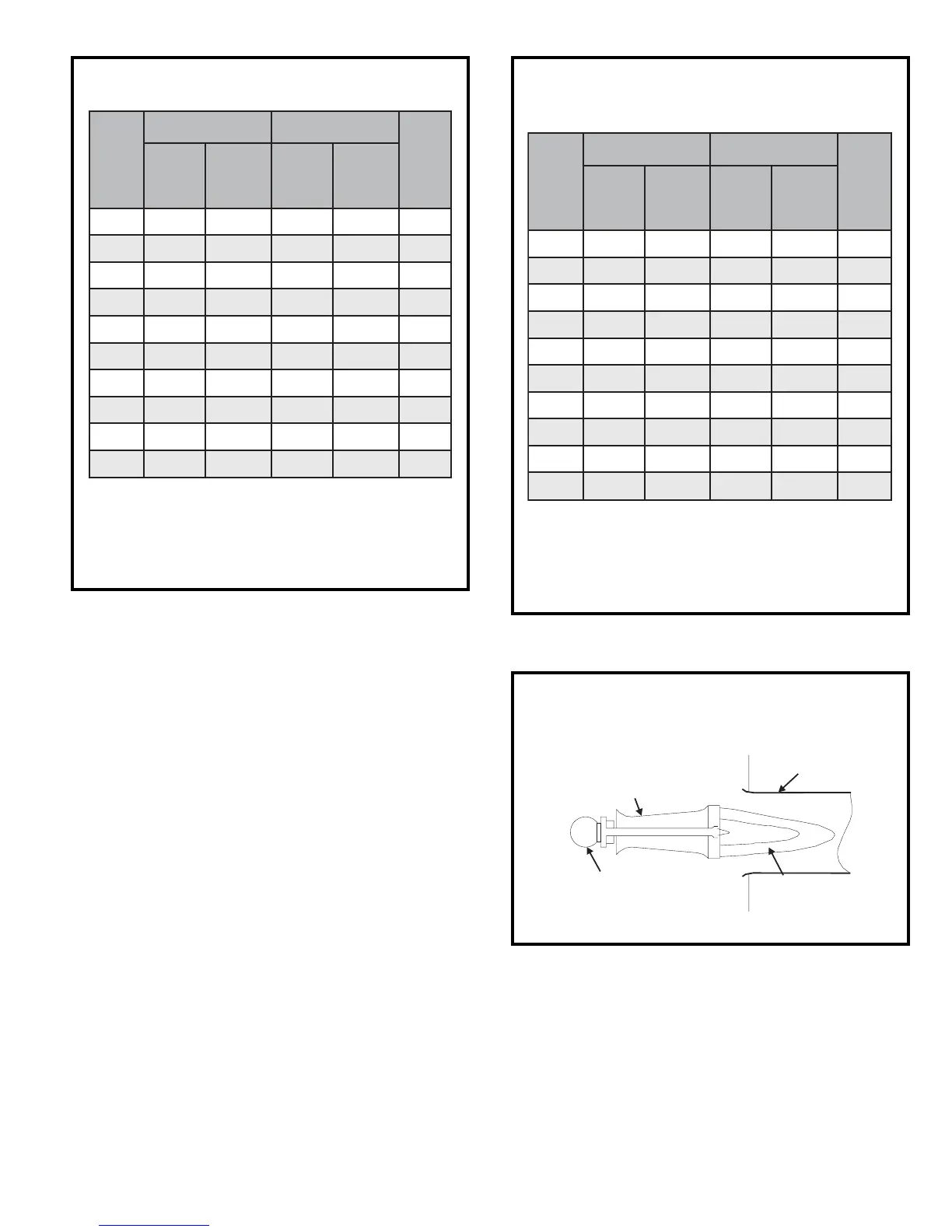

Table 3

Manifold Pressure vs. Altitude

(G1N80BU150 and CG80UB150 only)

* Consult local utility for actual heating value.

Furnace Input = Input Factor x 148,000

Above 7500 feet, call Technical Services at 1-800-448-

5872 ext. 2610.

edutitlA

).tf(

saGlarutaN )PL(enaporP

tupnI

rotcaF

gnitaeH

*eulaV

tf/UTB(

3

)

dlofinaM

erusserP

).C.W.ni(

gnitaeH

*eulaV

tf/UTB(

3

)

dlofinaM

erusserP

).C.W.ni(

000284914.3872200.016669.0

0003 419 14.3 6912 00.01 9949.0

000418814.3611200.012339.0

0054 568 14.3 7702 00.01 9429.0

000594802.3930214.90098.0

0055 338 81.3 0002 53.9 0978.0

000681861.3469192.90868.0

0056 208 41.3 7291 42.9 0758.0

000778721.3198181.90648.0

0057 177 11.3 3581 21.9 0538.0

It is recommended that this furnace be inspected by a

qualified service technician at the beginning of each heating

season.

Filters

Filters should be checked at least every 6 weeks. Dispos-

able filters should be replaced when dirty, and permanent

filters should be cleaned regularly. It is important to keep the

air filters clean, as dirty filters can restrict airflow and the

blower and induced draft motors depend upon sufficient air

flowing across and through them to keep from overheating.

Main Burners

Light the burners and allow to operate for a few minutes to

establish normal burning conditions. Observe the main

burner flames. Compare this observation to Figure 17 to

determine if proper flame adjustment is present. Flame

should be predominantly blue in color and strong in appear-

ance. Check that all burners are lit, and that the flame does

not impinge on the sides of the heat exchanger.

Distorted flame or yellow tipping of the natural gas main

burner flame, or long yellow tips on propane, may be

caused by lint accumulation or dirt inside the burner or

burner ports, at the air inlet between the burner and

manifold pipe, or obstructions over the main burner orifice.

Use a soft brush or vacuum to clean the affected areas.

Lubrication

The blower motor and induced draft motor are pre-lubri-

cated by the manufacturer and do not require further

lubricating attention. However, the motors should be

cleaned periodically to prevent the possibility of overheat-

ing due to an accumulation of dust and dirt on the windings

or on the motor exterior.

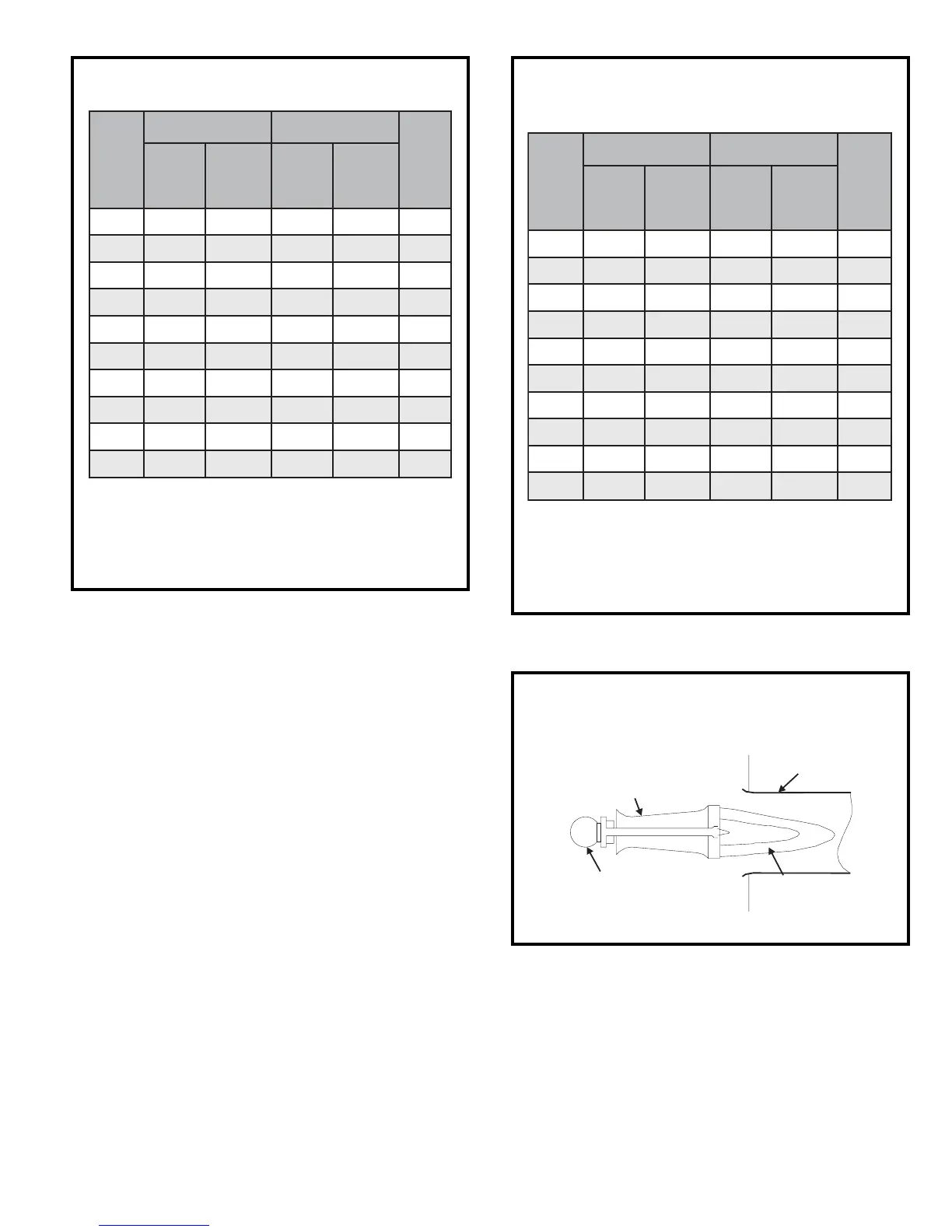

Typical Flame Appearance

(Main Burners)

Figure 17

Heat

Exchanger

Burner

Flame

(Blue Only)

Burner

Gas

Manifold

Table 2

Manifold Pressure vs. Altitude

* Consult local utility for actual heating value.

Furnace Input = Input Factor x Nameplate Input

Above 7500 feet, call Technical Services at 1-800-448-

5872 ext. 2610.

edutitlA

).tf(

saGlarutaN )PL(enaporP

tupnI

rotcaF

gnitaeH

*eulaV

tf/UTB(

3

)

dlofinaM

erusserP

).C.W.ni(

gnitaeH

*eulaV

tf/UTB(

3

)

dlofinaM

erusserP

).C.W.ni(

000284905.3872200.016669.0

0003 419 05.3 6912 00.01 9949.0

000418805.3611200.012339.0

0054 568 05.3 7702 00.01 9429.0

000594892.3930214.90098.0

0055 338 72.3 0002 53.9 0978.0

000681852.3469192.90868.0

0056 208 32.3 7291 42.9 0758.0

000778712.3198181.90648.0

0057 177 91.3 3581 21.9 0538.0

Loading...

Loading...