# 45464K003Page 4

Unconfined Space

An unconfined space is defined as “a space whose volume

is more than 50 cubic feet per 1000 BTU per hour of the

combined input rating of all appliances installed in that

space.” When a furnace is installed in an unconfined space

in a building, it can be assumed that the infiltration will be

sufficient to supply the required air. If the furnace is

installed in a ventilated attic or crawl space, it is assumed

that the infiltration is sufficient to supply the required air.

However, in a building of unusually tight construction,

additional outdoor air should be provided.

Confined Space

A confined space is defined as “a space whose volume is

less than 50 cubic feet per 1000 BTU per hour of the

combined input rating of all appliances installed in that

space.”

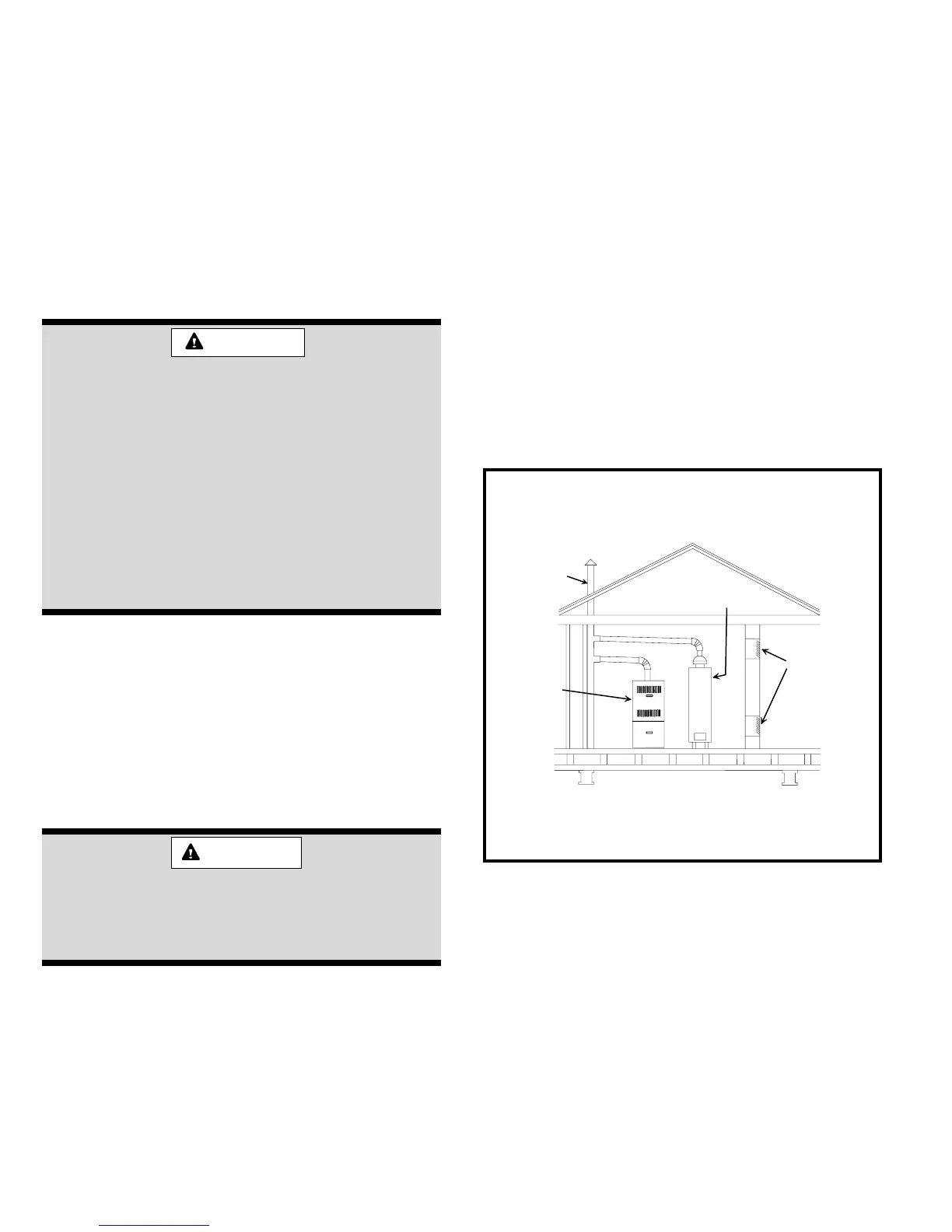

Confined Space Installation/Air from Inside Structure

If the furnace is installed in a confined space within the

building and combustion air is taken from a heated space,

the combustion air and ventilating air must enter and leave

the space through two permanent openings of equal area.

One opening shall be located within 12" of the ceiling and

the other within 12" of the floor, each having a free area of

1 square inch per 1000 BTU/HR of total input rating of all

appliances within the space and not less than 100 square

inches each (see Figure 3).

Confined Space Installation/Air from Outside Structure

If air from outside is brought in for combustion, the confined

space shall be provided with two permanent openings. One

opening shall be within 12" of the ceiling and one opening

within 12" of the floor. Several methods can be used to bring

the outside air in through these openings. The openings

shall open directly or by ducts with the outdoors, through

spaces (crawl space or attic) that freely open to the out-

doors, or indirectly through vertical ducts (see Figures 4 and

5). If any of these methods are used, each opening shall

have a free area of 1 square inch per 4000 BTU/HR of the

total input rating of all appliances within the enclosure.

Do not use the furnace as a heater in a

building under construction. The furnace can

be severely damaged due to the abnormal

environment caused by construction. Chlo-

rides from sources such as paint, stain, or

varnish; tile and counter cements; adhesives;

and foam insulation are abundant in a struc-

ture under construction and can be highly

corrosive. Low return air temperature can

cause condensation in the furnace and other

damage that can shorten the life of the unit.

CAUTION

G1N80BR, G1N80BT, CG80RB, and CG80TB models may

be installed as suspended units in the horizontal position.

These furnaces are not designed for direct attachment of

suspension rods to the furnace casing.

The suspending means must be field fabricated, and

should consist of two “cradles” made by attaching two rods

to a length of angle iron or suitable gage steel. Locate the

cradles so that they are as close as possible to the ends

of the furnace (this will provide access for removal of

major components such as the blower assembly). Provide

enough clearance between the suspension rods and the

furnace to allow removal of access panels.

Combustion and Ventilation Air

Adequate provisions for combustion air and ventilation of

furnace must be made. Refer to Section 5.3, “Air for

Combustion and Ventilation,” of the National Fuel Gas

Code, ANSI Z223.1/NFPA54 (latest edition), Sections 7.2,

7.3, or 7.4 of CSA B149.1 Natural Gas and Propane

Installation Codes (latest editions), or applicable provi-

sions of the local building codes.

Air openings in the front of the furnace must

be kept free of obstructions. Any obstruction

may cause improper operation that can result

in a fire hazard or carbon monoxide injury.

WARNING

Figure 3

Note: Each opening shall have a free area of at least one square

inch per 1000 BTU per hour of the total input rating of all

equipment in the enclosure, but not less than 100 square

inches.

Water

Heater

Chimney or

Gas Vent

Openings

Furnace

Equipment in Confined Space

All Air From Inside

Loading...

Loading...