Page 12

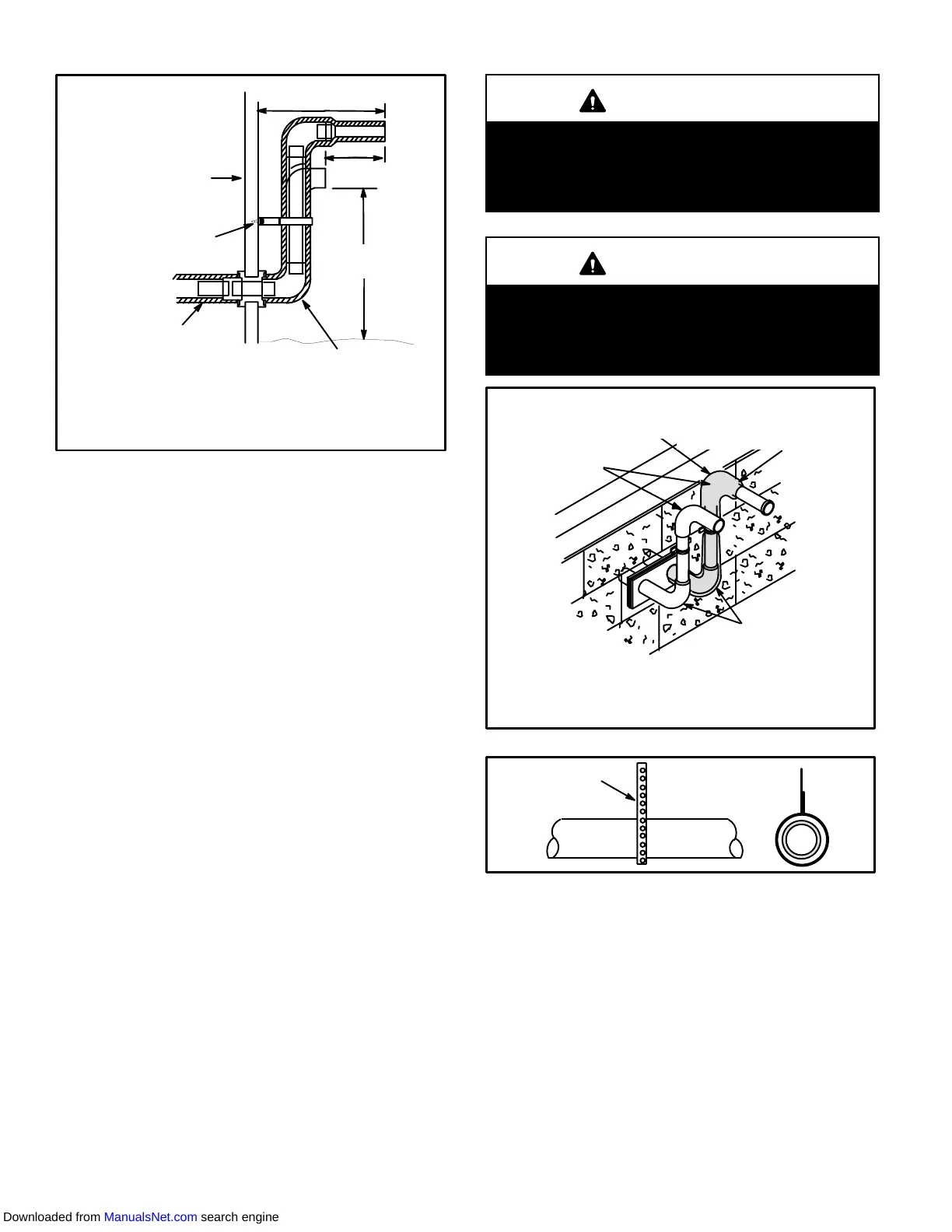

FIGURE 13

*This reducer is not necessary for G26-50 units using 1-1/2 in. venting.

See venting table 4 for maximum venting lengths with this arrangement.

12 (305) ABOVE

AVERAGE SNOW

ACCUMULATION

UNCONDITIONED

SPACE

12 (305) MIN. for 2 (51)

20 (508) MAX. for 3 (76)

8 (203)

MIN.

1/2 (13) FOAM

INSULATION

1/2 (13) FOAM

INSULATION IN

UNCONDITIONED

SPACE

PROVIDE SUPPORT

FOR INTAKE AND

EXHAUST LINES EVERY

36 (914)

OUTSIDE WALL

Inches(mm)

SIDE VIEW

WALL RING TERMINATION

(15F74) LB-49107CB for 2 in. (51) Venting

9 - Position termination ends so they are free from any obĆ

structions and above the level of snow accumulation

(where applicable). Termination ends must be a mini-

mum of 12 inches (305mm) above grade level. Do not

point into window wells, stairwells, alcoves, courtyard

areas or other recessed areas. Do not position terminaĆ

tion ends directly below roof eaves or above a walkway.

Since the G26 is a certified direct vent, Category IV gas

furnace, the location of the termination is limited by loĆ

cal building codes. In the absence of local codes, refer

to the current National Fuel Gas Code ANSI Z223-1 in

U.S.A., and current standards CAN/CGA-B149.1 /.2 of

the Natural Gas and Propane Installation Instructions in

Canada for details. The termination should be at least

12 inches (305mm) from any opening through which

flue products could enter the building.

When horizontally vented, minimum clearance for terĆ

mination from electric meters, gas meters, regulators

and relief equipment is 4 feet (1.2m) for US installaĆ

tions. Refer to the current CAN/CGA-B149.1 and .2 for

installations in Canada or with authorities having local

jurisdiction.

At vent termination, care must be taken to maintain

protective coatings over building materials (proĆ

longed exposure to exhaust condensate can destroy

protective coatings). It is recommended that the exĆ

haust outlet not be located within 6 feet (1.8m) of a

condensing unit because the condensate can damĆ

age the painted coating.

IMPORTANT

Combustion air intake inlet and exhaust outlet should

not be located within 6 feet (1.8m) of dryer vent or comĆ

bustion air inlet or outlet of another appliance. Piping

should not exit less than 3 feet (.91m) from opening

into another building.

IMPORTANT

For Canadian Installations Only:

In accordance to CAN/CGA-B149.1 and .2, the miniĆ

mum allowed distance between the combustion air

intake inlet and the exhaust outlet of other apĆ

pliances shall not be less than 12 inches (305mm).

FIGURE 14

Inches (mm)

FRONT VIEW

WALL TERMINATION

(22G44) LB-49107CD for 2(51) Venting

(44J40) LB-65701A for 3(76) Venting

3 (76) OR

2 (51) 90° ELBOW

1/2 (13)

FOAM

INSULATION

Inches(mm)

3 (76) OR

2 (51) 90° ELBOW

3 x 2 (76 x 51) OR

2 x 1-1/2 (51 x 38)

REDUCER BUSHING LOCATION

FOR OFFSET TERMINATION

Optional Turndown

(Not Shown)

May Be Used on

Intake Only

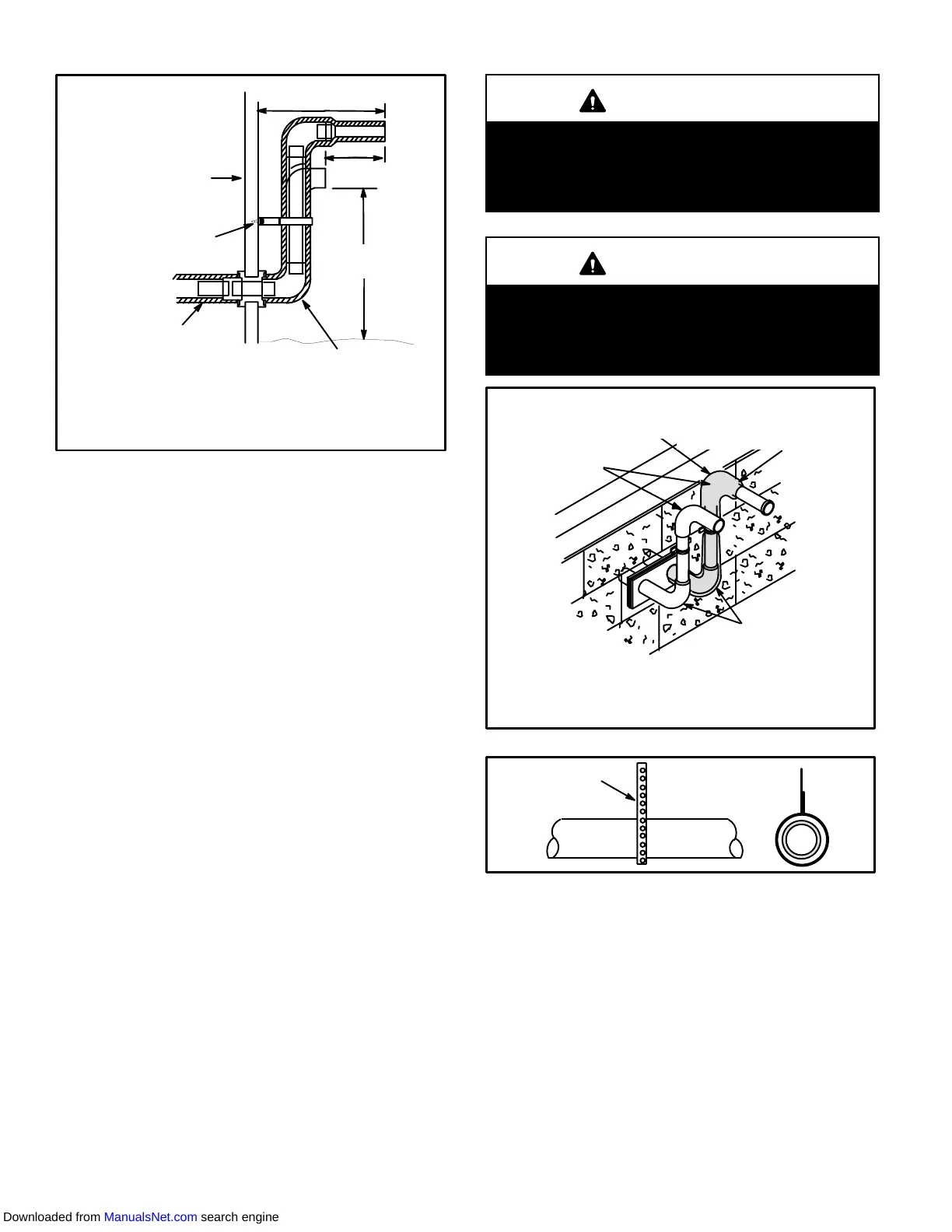

FIGURE 15

METAL OR PLASTIC

STRAPPING

OR LARGE WIRE TIES

10 - Suspend piping using hangers at a minimum of every

5 feet (1.52m) for schedule 40 PVC and every 3 feet

(.91m) for ABS-DWV, PVC-DWV, SPR-21 PVC, and

SDR-26 PVC piping. A suitable hanger can be fabriĆ

cated by using metal or plastic strapping or a large

wire tie.

11 - In areas where piping penetrates joists or interior

walls, hole must be large enough to allow clearance on

all sides of pipe through center of hole using a hanger.

12 - Isolate piping at the point where it exits the outside wall

or roof.

Downloaded from ManualsNet.com search engine

Loading...

Loading...