Page 41

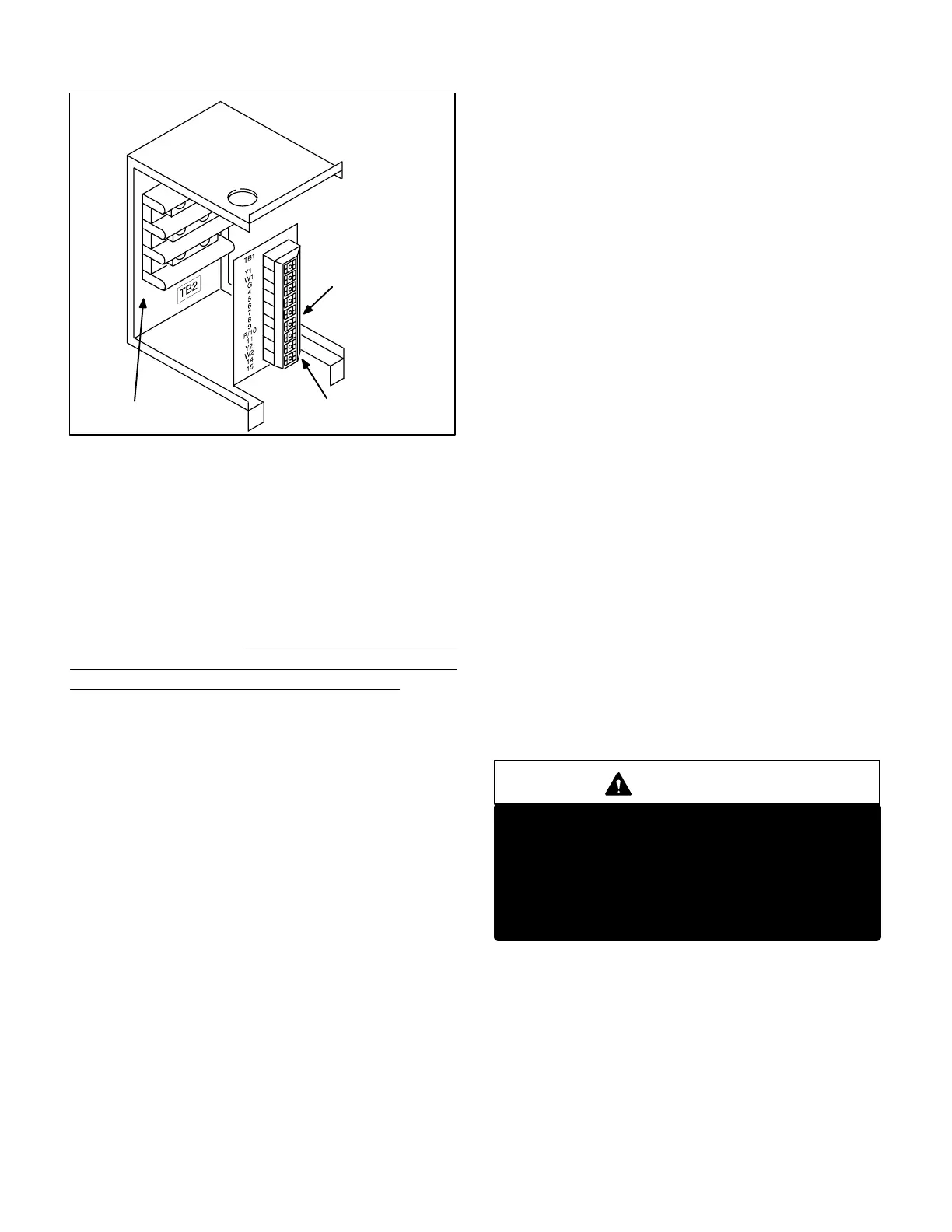

FIGURE 39

MAKE-UP BOX

12.5 TON AND LARG

ER UNITS ONLY

LOW VOLTAGE

TERMINAL STRIP TB1

LINE VOLTAGE

TERMINAL STRIP TB2

TO INSERT OR RELEASE

WIRE, DEPRESS CEN

TER

WITH PEN OR SMALL

SLOT SCREWDRIVER .

2-Line Voltage Make-Up Strip TB2

Line voltage terminal strip TB2 (figure 39) is provided in all

GCS16 series units to provide a means for connection of

all line voltage wiring. Knock-outs provided in the base pan

of the unit cabinet allow for passage of wires into conduit

and roof mounting frame. In 10 ton and smaller units, TB2

is located in the unit control box. In 12.5 ton and larger

units, TB2 is located in the blower compartment.

3-Low Voltage Terminal Strip TB1

All GCS16 units are equipped with a low voltage terminal

strip TB1. In 10 ton and smaller units, TB1 is located in the

unit control box. In 12.5 ton and larger units, TB1 is located

in the blower compartment (figure39). Most low voltage

(thermostat) electrical connections can be made to this

terminal strip. Knock-outs provided in the base pan of the

unit cabinet allow for passage of wires into conduit and

roof mounting frame. Special instructions are provided

where needed for low voltage connections that cannot be

made to the terminal strip. A detail drawing of TB1 is also

shown in figure 10.

III-ELECTRICAL CONNECTIONS

A-Power Supply

Refer to startup directions and refer closely to the unit wir

ing diagram when servicing. See unit nameplate for mini

mum circuit ampacity and maximum fuse size.

208/460/575 volt units are factory wired with red wire con

nected to control transformer primary. 230 volt units are

field wired with orange wire connected to control trans

former primary.

IV-PLACEMENT AND INSTALLATION

Make sure that the unit is installed in accordance with the

installation instructions and all applicable codes. See ac

cessories section for conditions requiring use of the op

tional roof mounting frame (RMF16).

V-STARTUP - OPERATION

A-Preliminary and Seasonal Checks

1- Make sure the unit is installed in accordance with the

installation instructions and applicable codes.

2- Inspect all electrical wiring, both field and factory

installed for loose connections. Tighten as required.

Refer to unit diagram located on inside of unit control

box cover.

3- Check to ensure that refrigerant lines are in good con

dition and do not rub against the cabinet or other re

frigerant lines.

4- Check voltage at the disconnect switch. Voltage must

be within the range listed on the nameplate. If not, con

sult the power company and have the voltage cor

rected before starting the unit.

5- Recheck voltage and amp draw with unit running. If

power is not within range listed on unit nameplate,

stop unit and consult power company. Refer to unit

nameplate for correct running amps.

6- Inspect and adjust blower belt (see section

VIII-C-Blower Belt Adjustment).

B-Cooling Startup

NOTE-The following is a generalized procedure and

does not apply to all thermostat control systems. Elec

tronic and ramping thermostat control systems may op

erate differently. Refer to the operation sequence sec

tion of this manual for more information.

WARNING

Crankcase heaters must be energized for 24

hours before attempting to start compressors.

Set thermostat so there is no compressor demand

before closing disconnect switch. Attempting to

start compressors during the 24hour warmup

period could result in damaged or failed compres

sors.

1- Set fan switch to AUTO or ON and move the system

selection switch to COOL. Adjust the thermostat to a

setting far enough below room temperature to bring

on all compressors. Compressors will start and cycle

on demand from the thermostat (allowing for unit and

thermostat time delays).

2- Each refrigerant circuit is charged with R-22 refrigerant.

See unit rating plate for correct charge amount.

3- Refer to Cooling Operation and Adjustment section

for proper method of checking charge.

Loading...

Loading...