Page 42

C-Heating Startup

1- Set thermostat to OFF position. Close manual knob

on gas valve(s).

2- Wait five minutes.

3- Open manual knob on gas valve(s), replace burner

access door and turn on unit electrical supply.

4- Set the fan switch to AUTO or ON and move the sys

tem selection switch to HEAT. Adjust the thermostat

setting above room temperature.

5- The combustion air blower immediately starts. The

burners light within 40 sec.

6- If the burners do not light the first time, it will attempt up

to two more times before locking out.

7- If lockout occurs, repeat the previous steps.

D-Safety or Emergency Shutdown

Turn off power to the unit.

VI-COOLING SYSTEM SERVICE CHECKS

GCS16 is factory charged and requires no further adjust

ment; however, charge should be checked periodically us

ing the approach method. The approach method

compares actual liquid temperature with the outdoor ambi

ent temperature. Thermometer wells have been provided

to allow accurate liquid temperature measurement.

A-Gauge Manifold Attachment

Service gauge ports are identified in figures 31 and 32. At

tach high pressure line to liquid line gauge port on ther

mometer well. Attach low pressure line to suction line ser

vice port.

B-Charging

This unit is factory charged and requires no further adjust

ment; however, check charge during start-up using the ap

proach method outlined below. The approach method

compares actual liquid temperature with the outdoor ambi

ent temperature. Thermometer wells have been provided

to allow accurate liquid temperature measurement.

If the system is completely void of refrigerant, the recom

mended and most accurate method of charging is to weigh

refrigerant into the unit according to the amount shown on

the unit nameplate and in the specifications table. If weighing

facilities are not available or if the unit is just low on charge,

use the following procedures:

WARNING

Do not exceed nameplate charge under any con

ditions. Compressor damage will result.

1- This method uses a thermometer inserted in the ther

mometer wells to check liquid line temperature. Make

sure thermometer wells are filled with oil before

checking.

2- IMPORTANT - Block compressor compartment with

access panel so air will not by-pass the coils.

3- Operate unit (all compressors) for at least five minutes

until pressures stabilize.

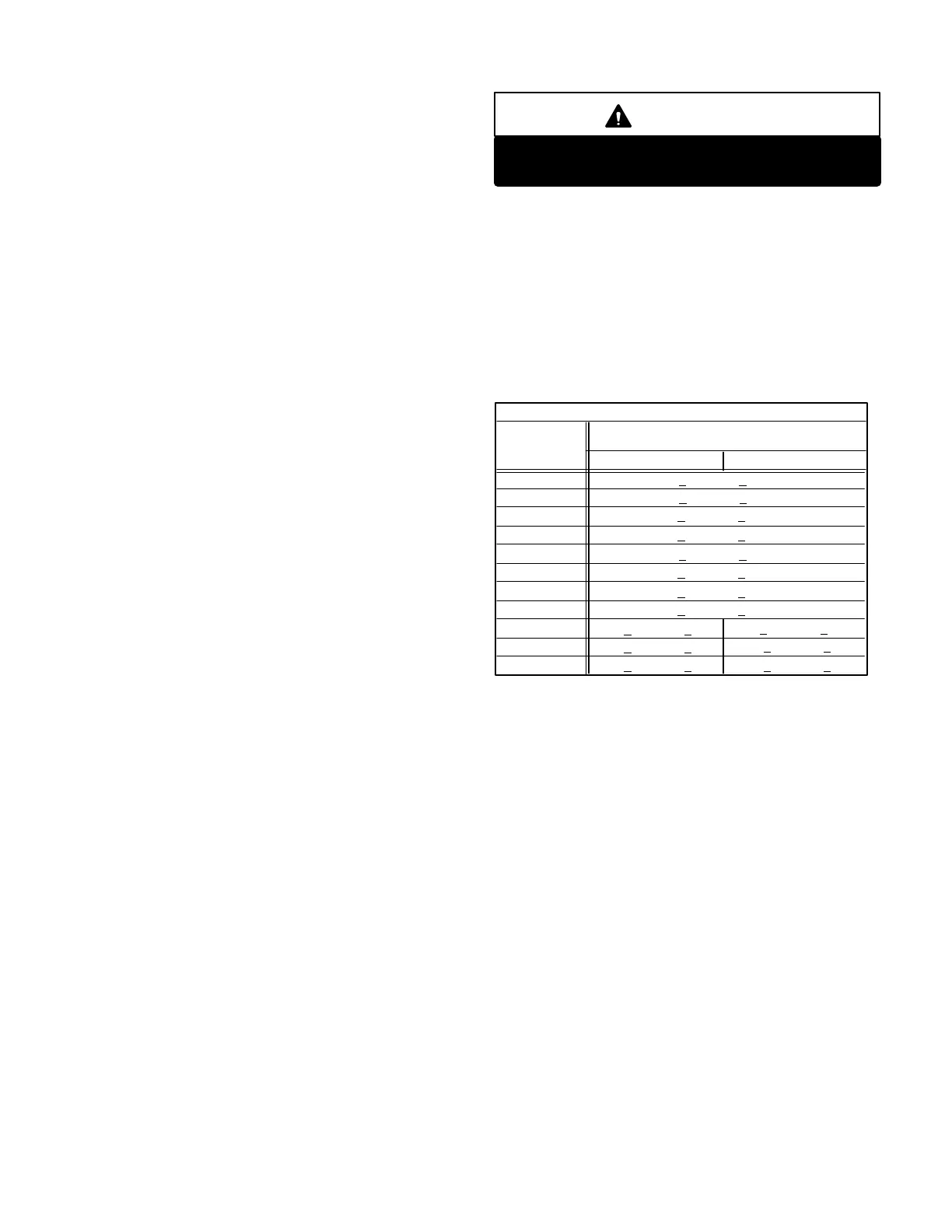

TABLE 6

APPROACH TEMPERATURE

UNIT Degrees F Liquid Line Warmer Than

Outdoor Air

GCS16-1853 7°F + 1 (3.9°C + 0.5)

GCS16823 7°F + 1 (3.9°C + 0.5)

GCS16953 8°F + 1 (4.5°C + 0.5)

6°F + 1 (3.3°C + 0.5)

6°F + 1 (3.3°C + 0.5)

GCS161353

GCS161603

7°F + 1 (3.9°C + 0.5)GCS162553*

7°F + 1 (3.9°C + 0.5)GCS162753*

7°F + 1 (3.9°C + 0.5)GCS163003*

7°F + 1 (3.9°C + 0.5)GCS162553

1st Stage 2nd Stage

8°F + 1 (4.5°C + 0.5)

8°F + 1 (4.5°C + 0.5)GCS162753

10°F + 1 (5.6°C + 0.5)

GCS163003

*Round cornered condenser coils.

Slab type condenser coils.

10°F + 1 (5.6°C + 0.5)9°F + 1 (5.1°C + 0.5)

4- Check each stage separately with all stages operat

ing. Compare liquid temperatures to outdoor ambient

temperature. Liquid line temperature should be a few

degrees warmer than the outdoor air temperature.

Table 6 shows how much warmer the liquid line should

be. For best results use same thermometer for both

readings.

Add refrigerant to make the liquid line cooler. Recover

refrigerant to make the liquid line warmer.

VII-HEATING SYSTEM SERVICE CHECKS

A-A.G.A./C.G.A. Applications

and Requirements

All GCS16s are A.G.A and C.G.A. design certified without

modification.

Loading...

Loading...