Page 20

FIGURE 18

FIGURE 19

GROUND

JOINT

UNION

AUTOMATIC

GAS VALVE

FIELD

PROVIDED

AND INSTALLED

GROUND

JOINT

UNION

Left Side Piping

(Standard)

Right Side Piping

(Alternate)

AUTOMATIC

GAS VALVE

DRIP LEG

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

(With 1/8 in. NPT

Plugged Ta p Shown)

MANUAL

MAIN SHUT-OFF

VALVE

(With 1/8 in. NPT

Plugged Ta p

Shown)

NOTE - BLACK IRON PIPE ONLY TO BE ROUTED INSIDE OF CABINET

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

GROUND

JOINT

UNION

DRIP LEG

MANUAL

MAIN SHUT-OFF

VALVE

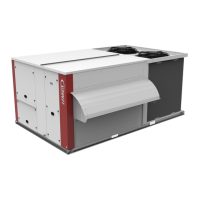

Possible Gas Piping Configurations

Horizontal Application

Left-Side Air Discharge

Horizontal Application

Right-Side Air Discharge

NOTE - BLACK IRON PIPE ONLY TO BE ROUTED INSIDE OF CABINET

FIELD

PROVIDED

AND

INSTALLED

Leak Check

After gas piping is completed, carefully check all eld-in-

stalled piping connections for gas leaks. Use a commer-

cially available leak detecting solution specically manu-

factured for leak detection. Never use an open ame to

test for gas leaks.

The furnace must be isolated from the gas supply system

by closing the individual manual shut-o valve during any

gas supply system at pressures greater than or equal to ½

psig. (3.48 kPa, 14 inches w.c.). This furnace and its com-

ponents are designed, manufactured and independent-

ly certied to comply with all applicable ANSI/CSA stan-

dards. A leak check of the furnace and its components is

not required.

IMPORTANT

When testing pressure of gas lines, gas valve must be

disconnected and isolated. See gure 28. Gas valves

can be damaged if subjected to pressures greater than

1/2 psig (3.48 kPa, 14 inches w.c.)..

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly after

leak test has been completed. Do not use matches,

candles, ame or other sources of ignition to check for

gas leaks.

MANUAL MAIN

SHUT-OFF VALVE

WILL NOT HOLD

NORMAL TEST

PRESSURE

CAP

ISOLATE

GAS VALVE

FURNACE

1/8 NPT PLUG

FIGURE 20

Loading...

Loading...