- 26 - Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05

4

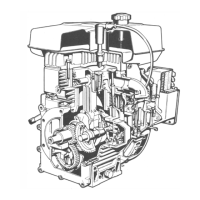

DISASSEMBLY/REASSEMBLY

Important

To locate specic topics, the reader should refer to the index.

– Besidesdisassemblyandreassemblyoperationsthischapteralsoincludescheckingandsettingspecications,dimensions,

repair and operating instructions.

– Always use original LOMBARDINI spare parts for proper repair operations.

– The operator must wash, clean and dry components and assemblies before installing them.

– The operator must make sure that the contact surfaces are intact, lubricate the coupling parts and protect those that are prone

to oxidation.

– Before any intervention, the operator should lay out all equipment and tools in such a way as to enable him to carry out operations

correctly and safely.

– For safety and convenience, you are advised to place the engine on a special rotating stand for engine overhauls.

– Before proceeding with operations, make sure that appropriate safety conditions are in place, in order to safeguard the operator

and any persons involved.

– Inordertoxassembliesand/orcomponentssecurely,theoperatormusttightenthefasteningpartsinacriss-crossoralternating

pattern.

– Assembliesand/orcomponentswithaspecictighteningtorquemustinitiallybefastenedatalevellowerthantheassigned

value,andthensubsequentlytightenedtothenaltorque.

RECOMMENDATIONS FOR OVERHAULS AND TUNING

Important

To locate specic topics, the reader should refer to the index.

– Before any intervention, the operator should lay out all equipment and tools in such a way as to enable him to carry out operations

correctly and safely.

– Theoperatormustcomplywiththespecicmeasuresdescribedinordertoavoiderrorsthatmightcausedamagetotheengine.

– Before carrying out any operation, clean the assemblies and/or components thoroughly and eliminate any deposits or residual

material.

– Wash the components with special detergent and do not use steam or hot water.

– Donotuseammableproducts(petrol,diesel,etc.)todegreaseorwashcomponents.Usespecialproducts.

– Dry all washed surfaces and components thoroughly with a jet of air or special cloths before reassembling them.

– Apply a layer of lubricant over all surfaces to protect them against oxidation.

– Check all components for intactness, wear and tear, seizure, cracks and/or faults to be sure that the engine is in good working

condition.

– Some mechanical parts must be replaced en bloc,togetherwiththeircoupledparts(e.g.valveguide/valveetc.)asspecied

in the spare parts catalogue.

Danger - Attention

During repair operations, when using compressed air, wear eye protection.

RECOMMENDATIONS FOR DISASSEMBLING AND ASSEMBLING

Loading...

Loading...