4

19

18

17

16

20

Rocker arm assemly

Loosen the screws which fasten the assembly to the head.

Whenrettingtightento50Nm.

Insidetherockerarmpinowstheoilthatlubricatestherocker

arms and feeds the hydraulic tappets.

To clean the rocker-arm pin inside, remove the two tightening

screws C attheends(g.17).

WhenrettingapplyadropofLoctite270ontothethreads.

Clearance

(mm)

Limit value (mm)

Dimensions

(mm)

Ref.

Disassembly / Reassembly

Valve removal

Components:

1 - Valve

2 - Lower spring seat

3 - Valve guide seal (for intake only)

4 - Spring

5 - Spring cap

6 - Cotters

Toremovethecottersrmlypressdownas showninthegure

20.

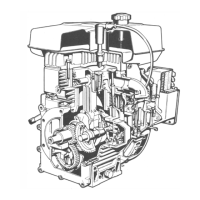

Cylinder head

Caution – Warning

Do not demount when hot or the part could become

deformed.

Do not remove when hot to avoid deformation.

Check cylinder head plane using a metal straight edge and

thickness gauge; if warpage exceeds 0.10 mm, level off by

removing a maximum 0.20 mm.

See pictures 56÷59 (pages 39÷40) for cylinder head

tightening.

To check the pin and the rocker-arm pin bearings for wear compare

the measured values with the parameters in the table below.

Table of pin-rocker arm dimensions

* Withbushingttedtotherockerarmandreamed.

Loading...

Loading...