4

36

35

33

31

34

32

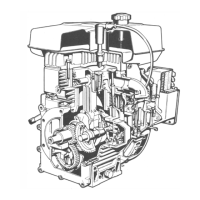

Precombustion chamber

The precombustion chamber can be extracted from the head banging

with a punch into the hole from the injector housing.

This procedure implies irreversible damages to the precombustion

chamber which will have to be replaced. In the assembly stage

line up the dowel 1 with the reference notch 2 located in the head.

Driving must be carried out evenly

The clearance allowance between the precombustion chamber

and its bore on the cylinder head is equal to 0.05 mm.

Using a depth gauge check that the precombustion chamber

plane protrusion does not exceed 0.04 and does not receed

over 0.02 mm from the head plane level.

The precombustion chamber plugs of the CHD PLUS series engines

have a different internal volume from the CHD series; therefore,

they are not interchangeable.

Disassembly / Reassembly

Hydraulic tappet components:

a) Tappet body

b) Plunger

c) Non-return valve

d) Spring

e) Push rod

f) Low-pressure chamber

g) High-pressure chamber

The hydraulic tappet is a device that enables elimination of

clearance between timing system components and provides the

following advantages:

- Reduces noise levels during operation.

- Reduces wear of the timing system components, thanks to there

being no collisions at the opening with consequent breaking of

theoillm.

- No maintenance.

Hydraulic diagram for feeding the tappets

1 Rocker-arm pin

2 Rocker arm

3 Push rod

4 Oil drainage

5 Hydraulic tappet

Hydraulic tappet valve control

Nota: If tappet is worn out along diameter B replace it.

No oversize tappets are available. If tappet/camshaft

surface is worn - replace

Clearance

(mm)

Limit value

(mm)

Dimensions

(mm)

Ref.

Loading...

Loading...