A (mm)

4

55

54

52 53

Piston - Retting

Connect piston to connecting rod after lubricating piston pin and

introducing it by exerting pressure with your thumb.

Position the two piston pin circlips and check that they are well

inside their seats.

Using a ring compressor introduce the piston into the cylinder

with combustion chamber facing the injection pump side.

Engine type No.of notches

Resulting clea-

rance (mm)

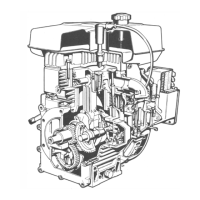

Disassembly / Reassembly

Cylinder head gasket

Caution – Warning

Remove the head gasket from its protective wrapping only

when ready for tting.

At B the gasket shows small semi-circular notches indicating

thickness.

Choose the proper head gasket considering that for each value

of A (maximum projection of the piston from the cylinder surface)

there is a matching gasket among the three available (with no

notch, one notch or two notches) to achieve a clearance volume

between 0.66 and 0.90 mm.

IntheLDW1503/1603enginestheheadgasketismadeofbre,

while in the LDW 2004 / 2204-T / 2204 / 2204-T engines the head

gasket is metal.

Note: The notches shown above protrude

from the cylinder head plane; you can

thus determine the gasket thickness

before taking down the head.

Piston position and clearance

To obtain a clearance of 0.67÷0.90 mm measure protrusion A of

all pistons from the cylinder plane and consider the A value of

the most protruding piston.

Perform this measurement along the engine axis.

Loading...

Loading...