90

92

91

Ref.

Dimensions (mm)

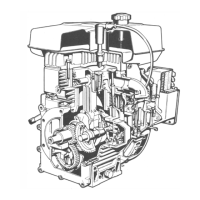

Crankshaft for engines with dynamic equalizer (only four-

cylinder engines).

The crankshaft comes with seat for the control gear of the

counter-rotating shaft dynamic balancer.

Components:

1 Control gear for counter-rotating shafts

2 Seat for the control gear of counter-rotating shafts

To replace the gear heat it up to 180°÷200°C.

Locate it into its seat so that the timing reference marks on the

teetharefoundontheyweelside.

Disassembly / Reassembly

Dynamic balancer (on request) - Adjustment of clearance

between teeth D and ring gear A

Followgures91and92.

Screw the screw B into support C taking care to centre the hole

in the mass of the gear D to lock it.

Fit the mass assembly under the crankcase so that the tooth

with reference E goes between the teeth with references F.

Fix the mass assembly with the four M10 screws to the

crankcase, provisionally tightening it to 40 Nm.

Remove screw B.

By making the driving shaft turn, check the clearance between

the ring gear A and the gear of mass D; set a comparator with

the feeler on one tooth of the timing system control gear G; by

turning the driving shaft a little way check the clearance which

must be 0.026÷0.067.

If the clearance measured does not come within the values

given, repeat the operation placing the 0.05 mm shims provided

for adjustment between the support C and the crankcase.

When mounting the balancer, lubricate the bushings with

Molikote then couple the two masses, taking into account the

references H and I.

PermanentlyxthesupportC to the crankcase by tightening the

screws to 50 Nm plus one turn of the wrench clockwise through

45°.

The four screws will have to be mounted with a few drops of

Loctite 242.

Loading...

Loading...