- 54 - Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05

4

114

113

115

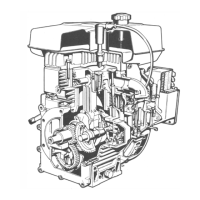

Disassembly / Reassembly

Valve timing without considering timing marks

Locate piston 1(onywheel)atthetopdeadcenter.Positiontwo

small rods A of the same length onto the tappets.

Rotate camshaft stopping when cylinder 1 tappets are in overlap

position (intake open exhaust closed).

Using the straight edge B check that rods A are at the same

length.

Mark the idler gear with camshaft and timing gear.

Camshaft timing

Fit idler gear B by making timing mark 2 coincide with timing

mark 1 on the camshaft control gear A and mark 3 with 4 on the

timing gear C.

Valve timing check

Check valve timing at the crankshaft.

Thevaluesshownarecheckedattheywheelcircumference(with

ywheeldiameterof290eachdegreecorrespondsto2.53mm).

Set valve clearance at 0.65-0.70 mm (after checking reset the

value to 0.15 mm).

Set dial gauge on intake valve to a zero value; by rotating the

crankshaft according to its direction of rotation you can measure

α

(intake valve opening advance referred to top dead center S) and

β (intake valve closing delay referred to bottom dead center I).

Follow the same procedure for exhaust valves checking

γ (exhaust

valve opening advance )and

δ ( exhaust valve closing delay).

Loading...

Loading...