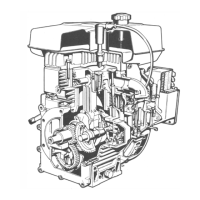

- 59 - Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05

5

124

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

.........................................................................................................................................................................

Checking actuator setting - "Waste gate" valve control rod

stroke adjustment

Important

This test must be done with the engine stationary.

Disconnect pipe 7 from the compressor side.

Using a T coupling, connect up with a pressure gauge 4 (scale

from zero to 2 bar) and with the compressed air mains pipe

complete with reduction unit 5.

The mains air pressure must be 1.5÷2.0 bar.

Make a hole B diameter 1.5 mm in the pressure gauge pipe

where part of the air will escape which has the purpose of

stabilizing the pressure in the pressure gauge.

Use the reduction unit 5 to send air to the actuator so as to

make terminal 2 of A move forward (A = 1 mm).

Position a comparator 6 so that the feeler rests on the terminal

2.

The pressure read on the pressure gauge must be 830÷890 mm

Hg (1.11÷1.19 bar).

If the pressure is lower than the given value, proceed as follows:

- Unscrew the lock nut 1.

- Remove the split pin 9 and disconnect the rod 8.

- Keeping the rod stationary, screw the terminal 2 to reach the

setting pressure.

While the terminal is rotating the rod must undergo no twisting.

Notes :

Loading...

Loading...