152

151

153

8

Electric fuel pump (24V)

The use of the electric pump is foreseen for certain applications

(where the engine has to be started at very low temperatures).

Assembly notes:

When the electric fuel pump is installed in a diesel engine, it is

necessary to:

1) Removethelterttedatthepumpintake(intakeside).

2) Inserttheprelterupstreamofthepump(intakeside).

3) The electric pump on the application must be at such a height

from the minimum tank level that it generates a maximum

pressure drop equal to a column of 500 mm of water.

4) Avoid running dry due to emptying of the intake pipeline, inserting

a non-return valve.

Features:

Pressure: 0.44 / 0.56 bars

Max capacity: 100 l/h

Features

Pumping

Sealing

valve

Support

clump

Intake

side

Volume 25 mm

3

1 hole Ø 0,81

Volume 25 mm

3

1 hole Ø 0,81

Volume 25 mm

3

3 holes Ø 1,5

Injection pump

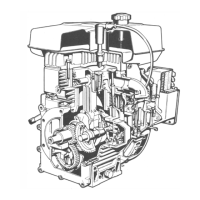

Theinjectionpumpofasimplied Q type has been designed by

LOMBARDINI for installation on engines of the CHD series.

The injection system includes three or four separate pumps

each of which feeds a cylinder.

Located on the crankcase at the level of the corresponding

cylinder, pumps are directly operated by the camshaft.

All high pressure tubes between injector and pump A feature the

same shape and dimensions.

Injection pump disassembly

Release the spring from the cap and remove the plunger.

Two pins keep the upper cap connected to the pump body; pry

with a tool between the pump body and the cap.

Injection pump components:

1 Delivery union 8 Spring

2 Spacer 9 Upper cap

3 Spring 10 Plunger pumping

4 Gasket 11 Lever

5 Delivery valve 12 Pin

6 Gasket 13 Body

7 Cap

A Fuel feed union

B Fuel dischrge union

CPumpange

D Barrel pumping

E Fuel control helix

Note: Union A and B, ange C and barrel D form an integral

part of the pump body.

Fuel system

Loading...

Loading...