- 72 - Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05

172

171

170

168 169

8

Injection timing correction by changing the pad thickness

Should it be necessary to correct the injection static advance,

remove the injection pump from the engine block and replace pad

B inside the injection tappets with one of a different thickness (to

extract pad B use a magnet C).

Its value is printed on the lower part of the pad.

Eight spare pads are supplied for the advance variations and their

thickness can vary from 4 to 4.7 mm.

The gasket A,betweentheinjectionpumpangeandtheengine

block, is only one, with the only task of preventing any possible

oil leaks.

Previously, to vary the injection advance, gaskets of different

thicknesses were used between the injection pump surface and

the engine block surface (in effect, gasket A without sealing rubber

border).

Injector setting

Connect the injector to a injection test stand and check that the

pressure setting is 140 / 150 bar.

Adding the shims 9 increases the pressure setting, reducing their

number lowers it.

Eleven spare setting shims 9 are included, their measurements

range from 1 to 2 mm.

When spring 10 is replaced, calibration must be carried out at a

pressure 10 bars higher than the nominal pressure (160 bar) to

counterbalance bedding in the operation.

Check needle valve sealing by slowly moving the hand pump

until approximately 120 bar per 10 seconds.

Replace nozzle 12 in case of dripping.

The torque of the injector ring nut is 70 ÷ 90 Nm.

Whenever maintenance operations are carried out on the

injector replace the seal ring 1.

Introduce seal ring 1 into the injector housing with the sealing

surfacefacingupwards(seegure171).

See page 22 for maintenance intervals.

Fix injector to the head tightening to 70 Nm.

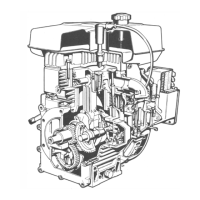

Injector (pin type)

Components:

1 Fuel inlet 7 Delivery union

2 Filter 8Backowunion

3 Body 9 Setting shims

4 Delivery duct 10 Pressure spring

5 Pad 11 Pressure pin

6 Clamping ring nut 12 Nozzle

13 Fireproof bulkhead

Fuel system

Loading...

Loading...