MAINTENANCE MANUAL OF ENGINE

129

Chapter 3 Inspection and adjustment

1. Inspecting valve clearance (mm)

Cause:

The compressive force of the cylinder is insufficient,

and there is black smoke and abnormal sound dur-

ing exhausting.

Equipment:

Open-end spanner, flat-tip screw driver, and feeler

gauge

Test steps and adjustment:

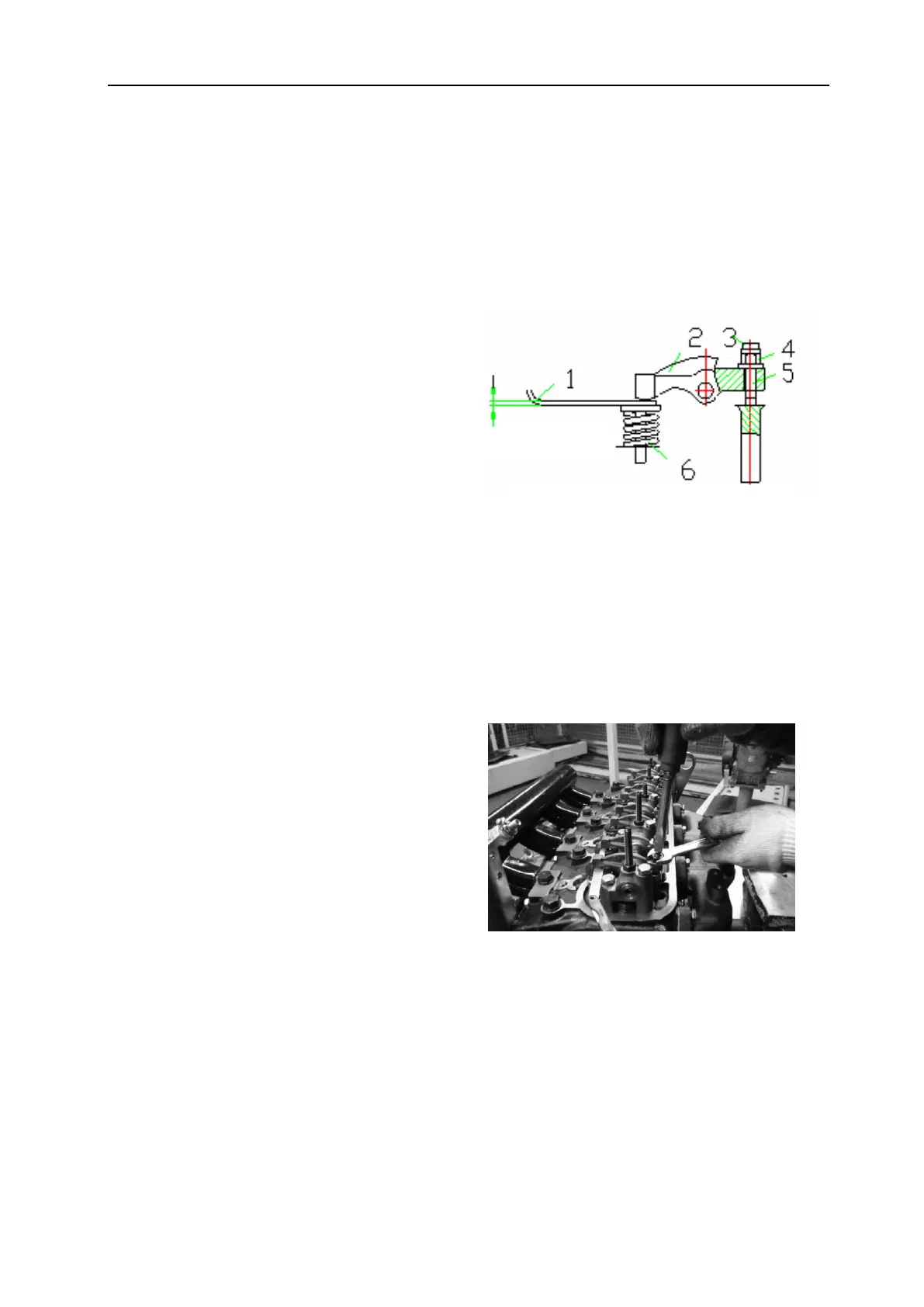

1. Dismantle the cylinder head cover, and inspect

and tighten the hold-down nut for the rocker arm

seat.

2. Turn the crankshaft to the position where the pis-

tons of the 1st cylinder and 4th cylinder are placed

at the upper dead point (the "0" scale line on the

crankshaft pulley is aligned with the pointer on the

timing gear chamber cover at this moment; among

them, if the intake valve and exhaust valve of one

cylinder must be closed simultaneously, the piston

of this cylinder is placed at the upper dead point in

the compression stroke).

3. Release the locknut, and use a screwdriver to turn

the adjusting screw, as well as insert the feeler

gauge into the intake valve and exhaust valve of the

1st cylinder, intake valve of the 2nd cylinder and

exhaust valve of the 3rd cylinder to inspect and ad-

just the clearance, so that the cold clearance is kept

within 0.30~0.35mm.

4. During adjustment, the valve should be tightened

by such means that the valve push rod can be turned

evenly by fingers. After being adjusted properly, it

is required to tighten the locknut firmly to prevent

looseness during operation.

5. According to the operating sequence of the

cylinders (the cylinders are operated in such se-

quence of 1-3-2 for the three-cylinder engine, and

1-3-4-2 for the four-cylinder engine), rotate the

crankshaft by one turn (namely 360°), and inspect

and adjust clearance of the remaining valves by the

method above (note that the valve clearance cannot

be adjusted by turning the crankshaft in reverse di-

rection).

Specification:

Intake valve clearance (cold state): 0.20-0.25 mm

Exhaust valve clearance (cold state): 0.25-0.30 mm

Test results:

If the problem remains unresolved after being ad-

justed as per requirements, other causes should be

taken account of.

1. The piston ring is deposited with carbon, jammed

or worn.

2. The cylinder head gasket is air-leaked.

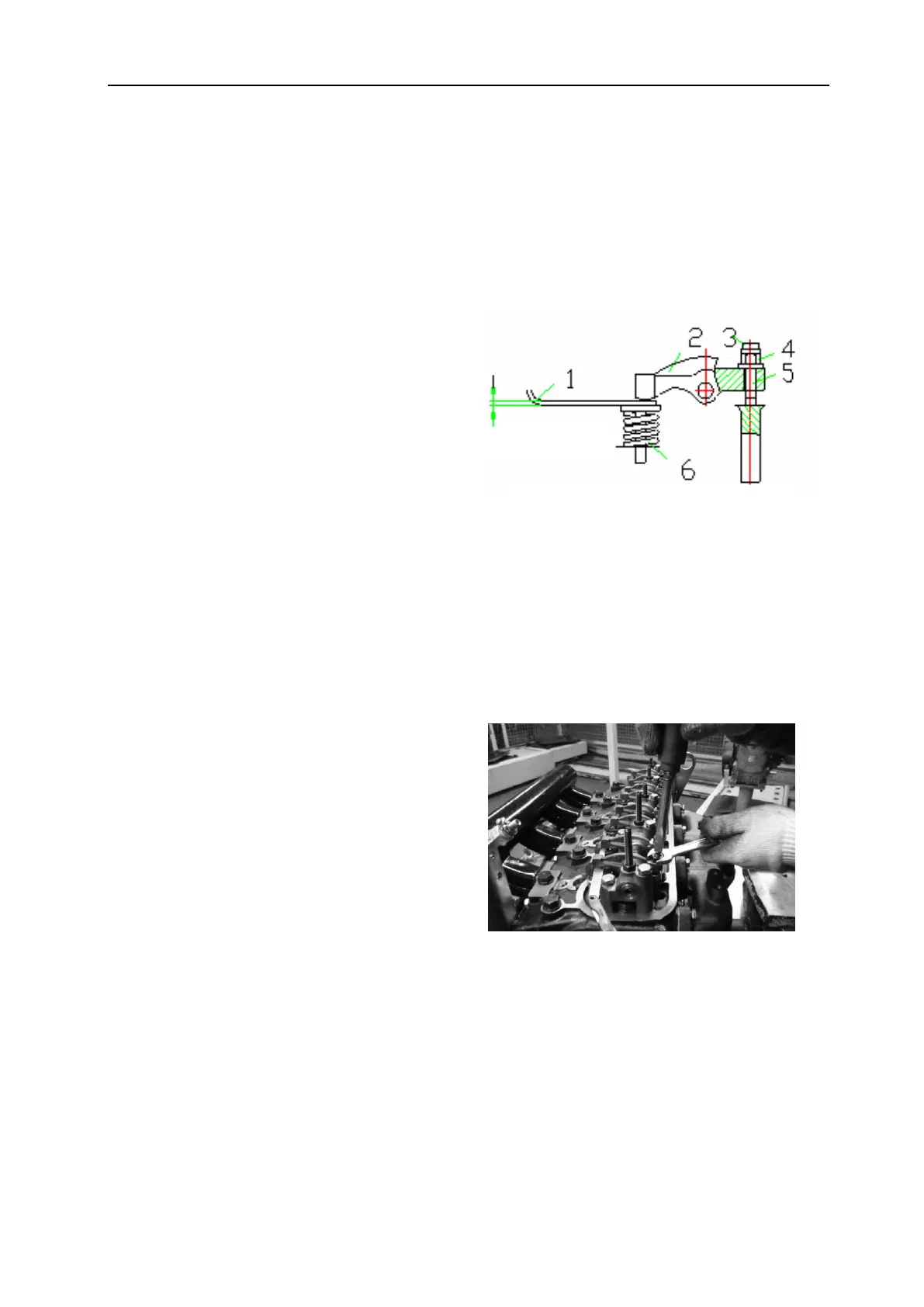

1-Feeler gauge

2-Rocker arm

3-Adjusting screw

4-Locknut

5-Push rod

6-Valve spring

7-Valve clearance

Loading...

Loading...