MAINTENANCE MANUAL OF ENGINE

139

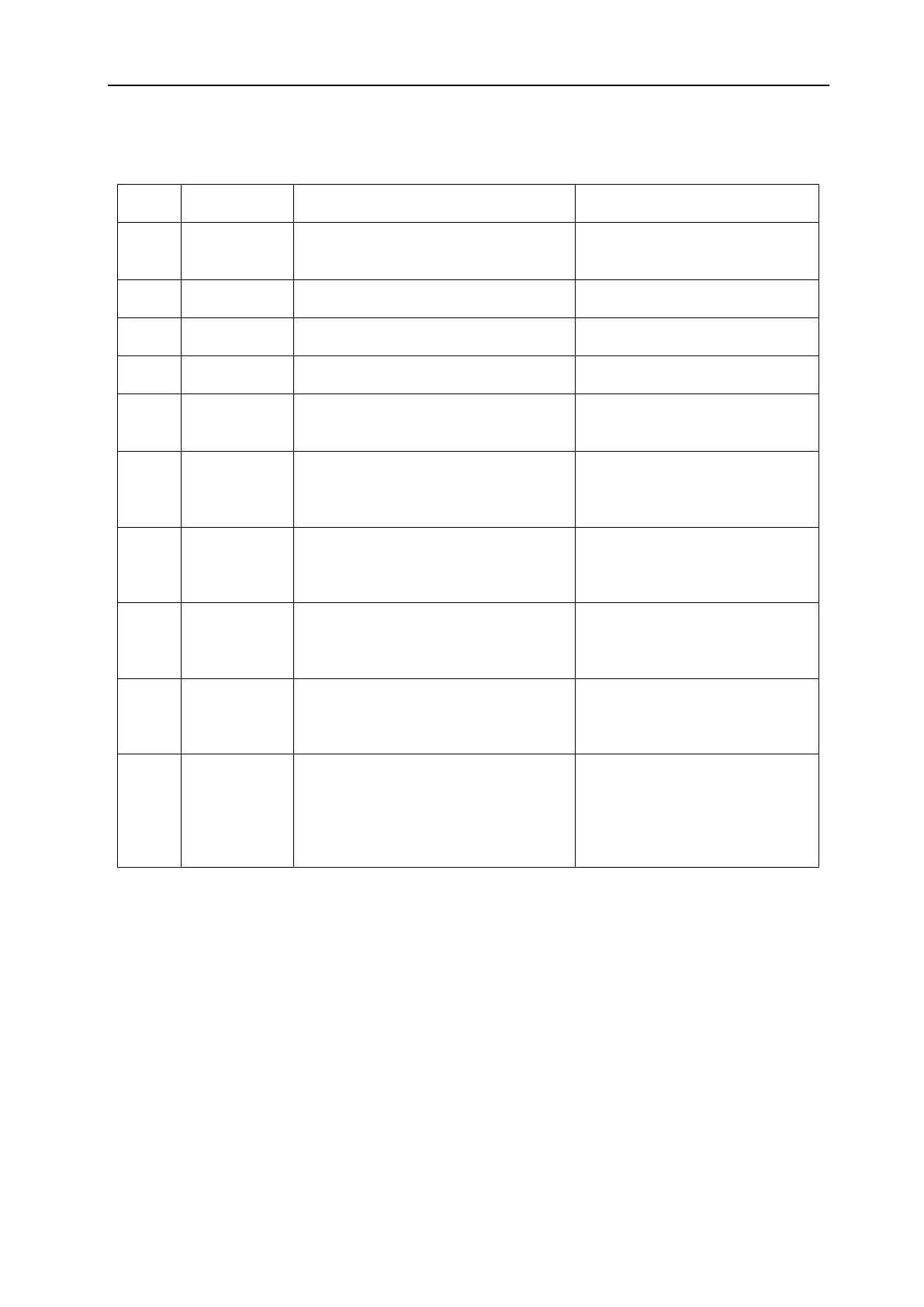

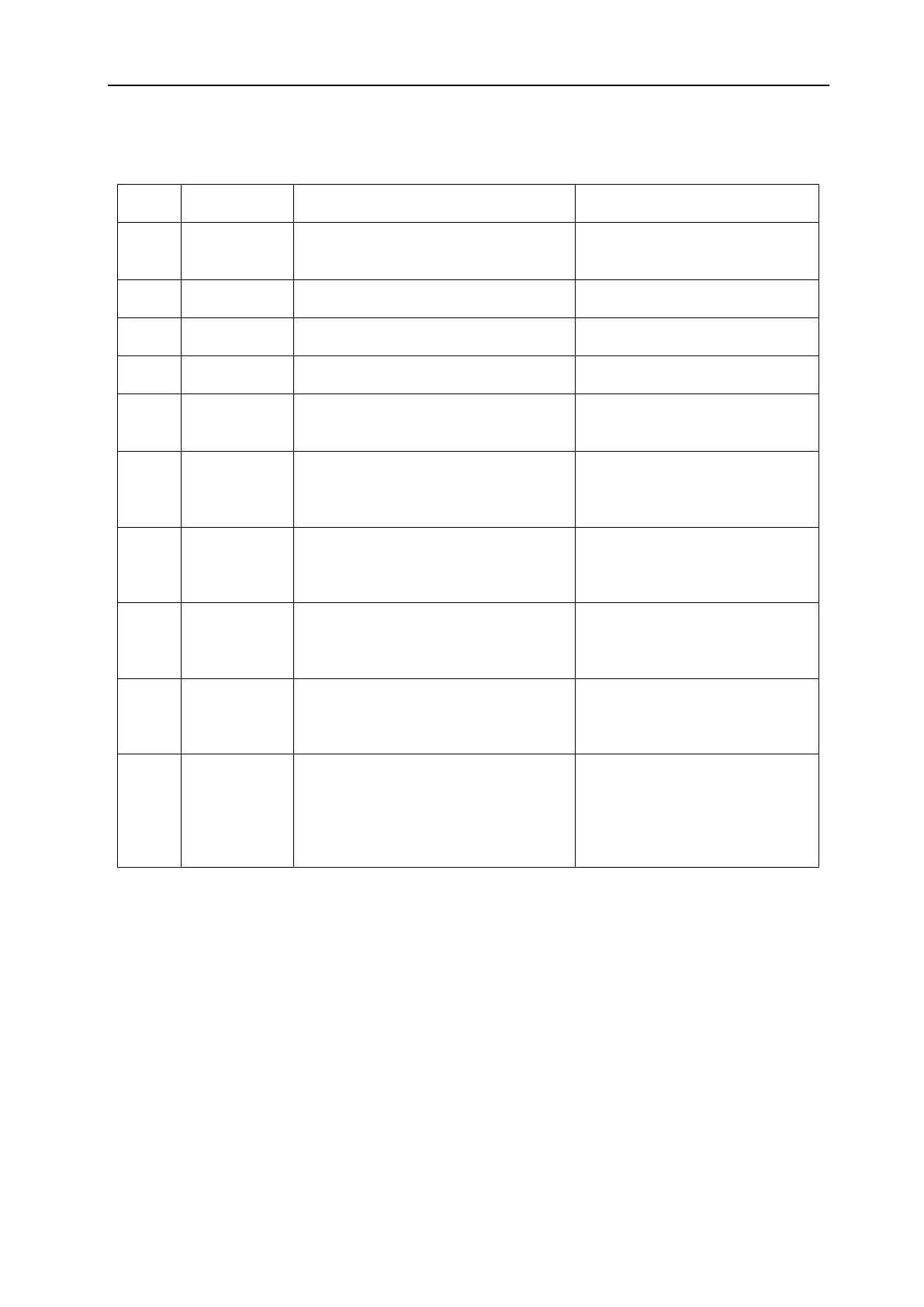

7. Abnormal sound from the diesel engine

Fuel supply

advance angle

The fuel supply advance angle is too

big, and there is rhythmic metallic

knocking sound.

Adjust the fuel supply advance

angle to 16°±1°

The fuel drips from fuel injector or the

needle valve is stuck.

Repair or replace (Refer to Sec-

tion 6, Chapter 3 of this Part)

The valve clearance is too big, and there

is clear and rhythmic knocking.

Adjustment (Refer to Section 1,

Chapter 3 of this Part)

The piston is in contact with the valve.

Adjustment (Refer to Section 1,

Chapter 3 of this Part)

The cylinder head thickness is insuffi-

cient, and the piston contacts the cylin-

der head.

Change the cylinder head gasket.

Valve spring,

valve push

rod, and valve

tappet

The valve spring is broken, the valve

push rod is bent, and the valve tappet is

worn, resulting in a slight knocking

from the valve mechanism.

Change the damaged part (Refer

to Chapter 1, Part II)

Piston and

cylinder liner

The clearance between piston and cyl-

inder liner is too big, but such sound is

weakened as the diesel engine tempera-

ture rises.

Repair or change the piston, cyl-

inder liner, piston ring and piston

pin (Refer to Chapter 1 and Chap-

ter 2, Part II).

Connecting

rod bearing

shell

The connecting rod bearing shell clear-

ance is too big. When the speed de-

creases suddenly, a heavy and strong

whomp can be heard.

Change the connecting rod bear-

ing shell bushing (Refer to Chap-

ter 2, Part II).

Connecting

rod bushing

and piston pin

The clearance between connecting rod

bushing and piston pin is too big. Such

sound is slightly sharp, especially clear

during idling.

Change the connecting rod and

piston pin bush (Refer to Chapter

2, Part II)

The wear of the crankshaft thrust plate

will lead to excessive axial clearance,

and it is possible to hear knocking pro-

duced from forward and backward

movement of the crankshaft during

idling.

Loading...

Loading...