MAINTENANCE MANUAL OF ENGINE

43

Chapter 2 Dismantling/installing the crank-link mechanism

1. Maintenance equipments and tools

Special tools:

16/19 Open-end wrench, 13 socket wrench, 18 socket wrench, digital torque wrench, adjustable torque

wrench

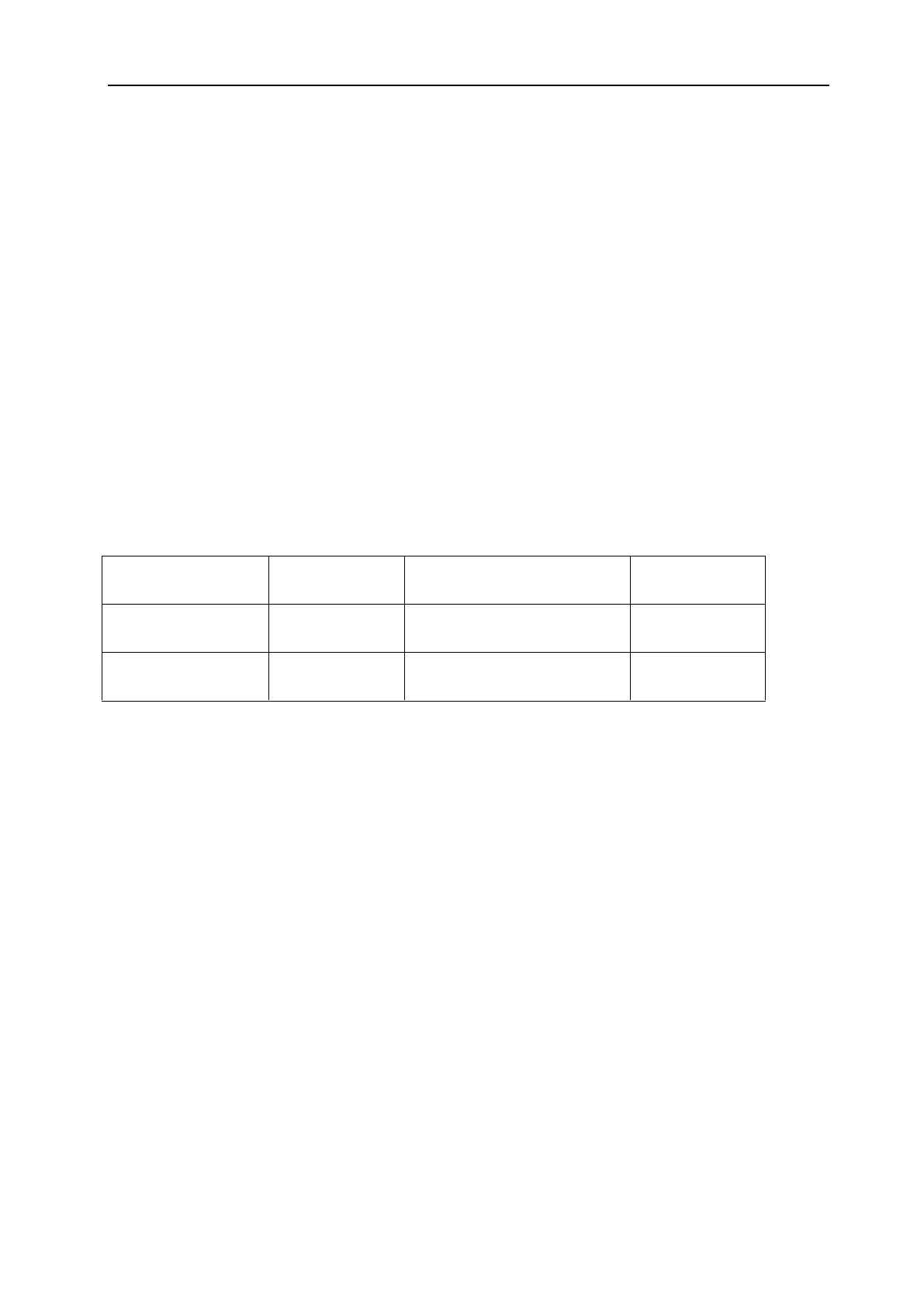

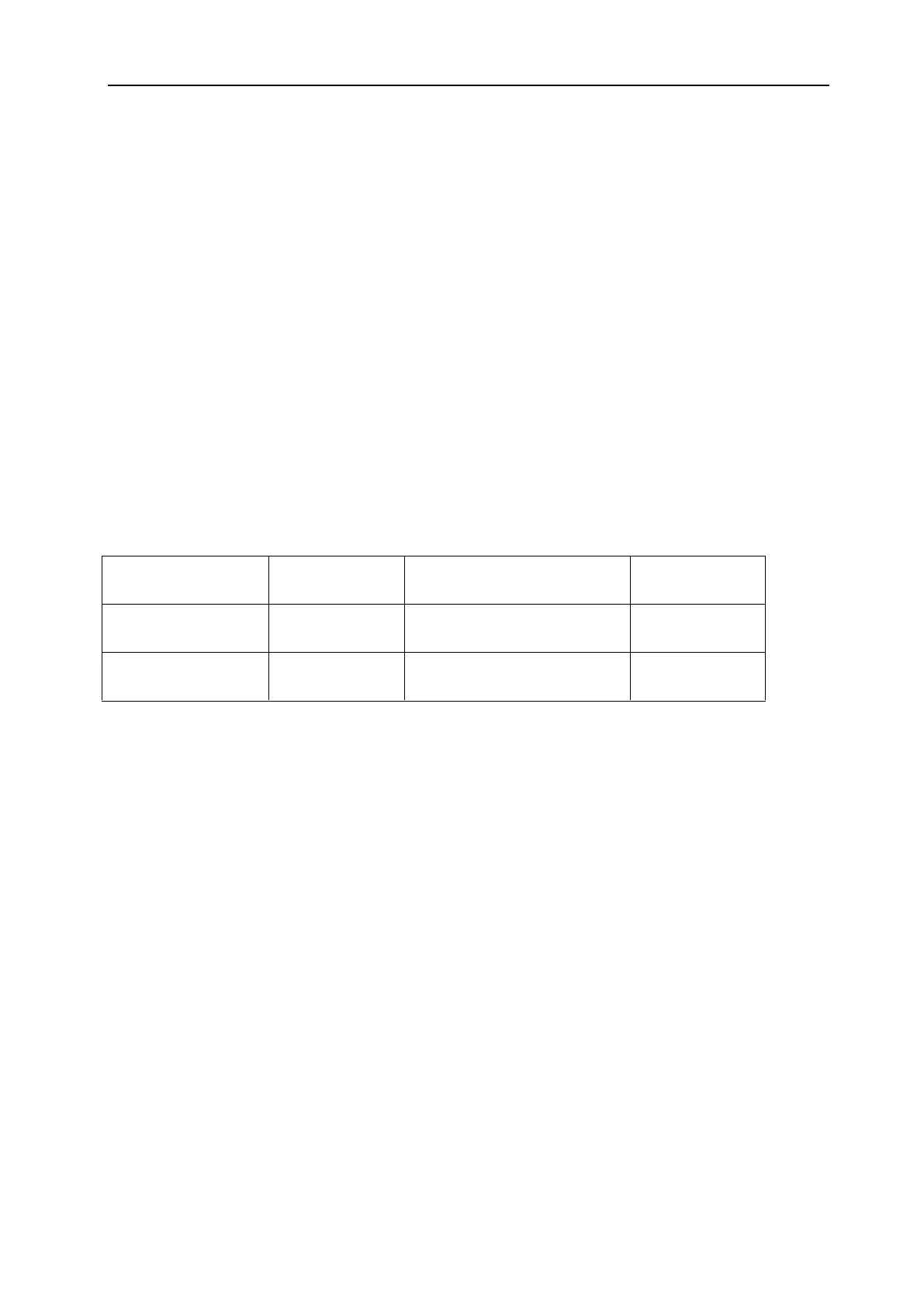

2. Torque and data

2.1. Torque requirements

2.2 Data

Piston ring-naturally aspirated engine

First gaseous ring------------------------------------------------chamfer on cylindrical surface and top of inner face

Second gaseous ring---------------------------------------------conical surface, cast iron

Oil ring------------------------------------------------------------spiral spring-weighted

First ring width---------------------------------------- ------------3.6±0.1 mm

Second ring width-------------------------------------------------3.5±0.1 mm

Third ring width---------------------------------------------------3.3±0.1 mm

Clearance of first ring in groove--------------------------------0.095+0.128 mm

Clearance of second ring in groove---------------------------- 0.04-0.072 mm

Clearance of third ring in groove------------------------------- 0.03-0.062 mm

Opening clearance of first ring----------------------------------11-13 mm

Opening clearance of second ring-------------------------------11-13 mm

Opening clearance of third ring--------------------------------- 9-11 mm

Loading...

Loading...