Installation 37/56

RE 93221-01-B/07.2013, A22VG Series 40, Bosch Rexroth AG

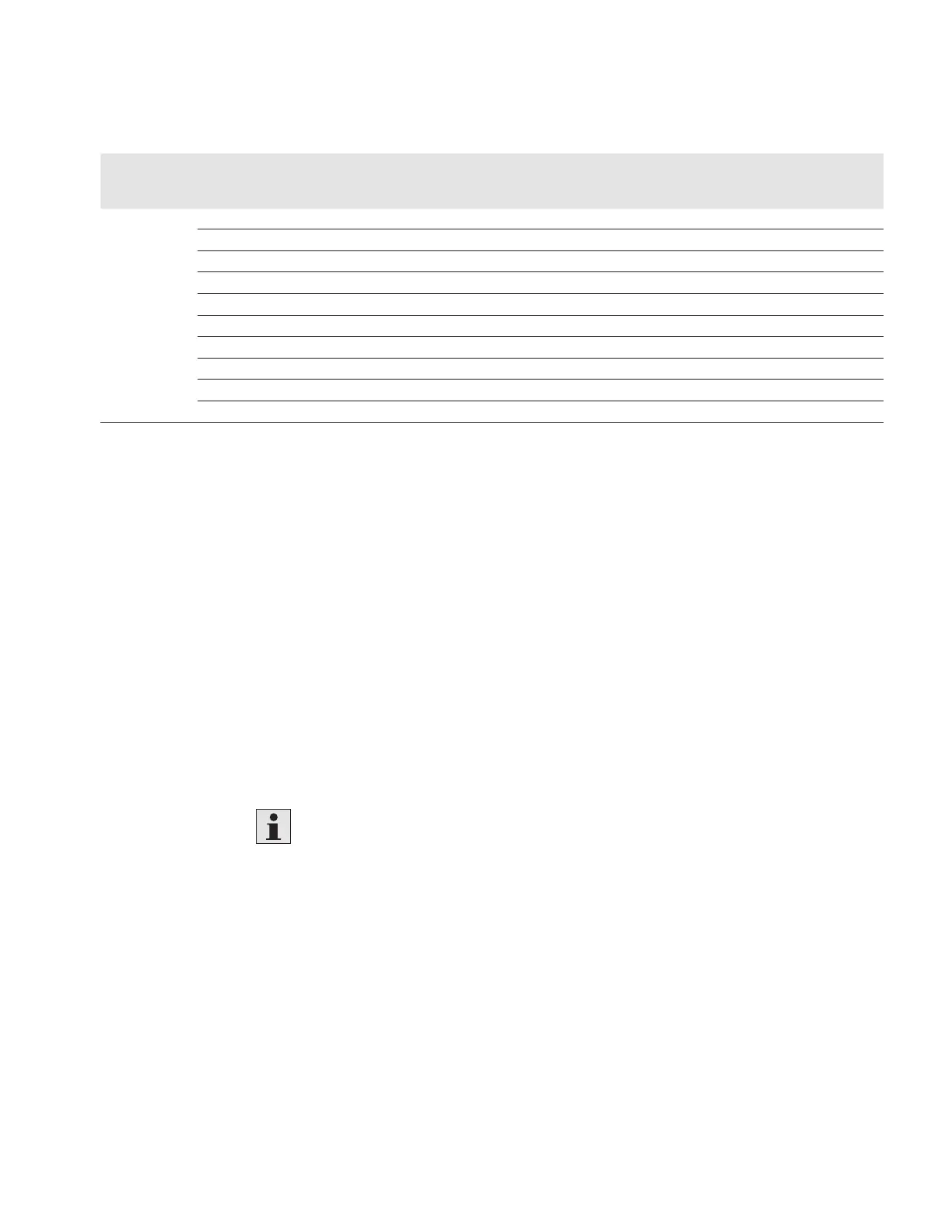

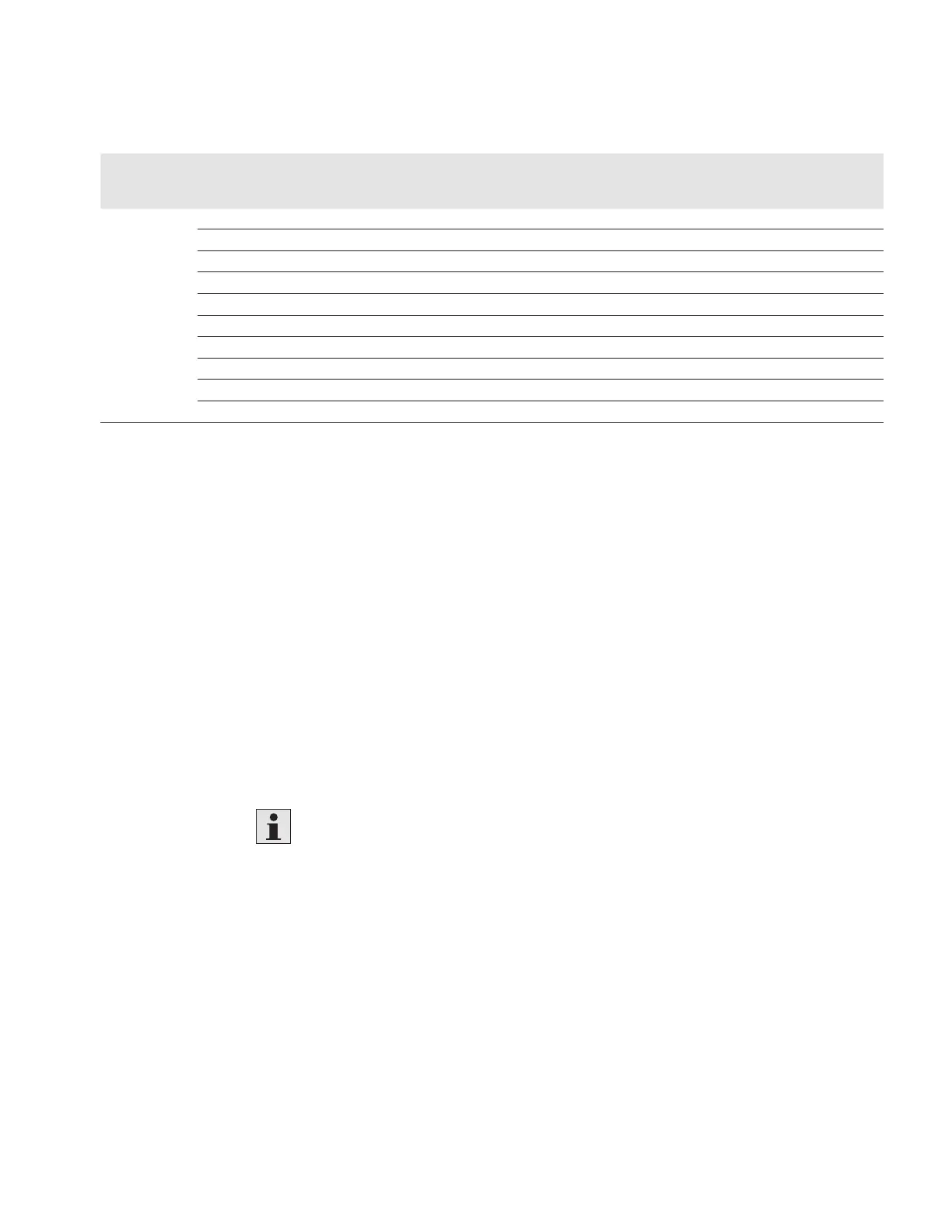

Table 11: Tightening torques of the female threads and threaded plugs

Ports

Maximum permissible

tightening torque of the

female threads M

Gmax

Required tightening torque of

the threaded plugs M

V

WAF

hexagon socket of the

threaded plugs

Standard Thread size

ISO 11926 5/16-24 UNF-2B 10 Nm 7 Nm 1/8 in

3/8-24 UNF-2B 20 Nm 10 Nm 5/32 in

7/16-20 UNF-2B 40 Nm 18 Nm 3/16 in

9/16-18 UNF-2B 80 Nm 35 Nm 1/4 in

3/4-16 UNF-2B 160 Nm 70 Nm 5/16 in

7/8-14 UNF-2B 240 Nm 110 Nm 3/8 in

1 1/16-12 UN-2B 360 Nm 170 Nm 9/16 in

1 5/16-12 UN-2B 540 Nm 270 Nm 5/8 in

1 5/8-12 UN-2B 960 Nm 320 Nm 3/4 in

1 7/8-12 UN-2B 1200 Nm 390 Nm 3/4 in

To connect the axial piston unit to the hydraulic system:

1. Remove the protection plugs and threaded plugs at the ports at which the

connections are to be made according to the hydraulic schematic.

2. Make sure that the sealing surfaces of the hydraulic ports and functional surfaces

are not damaged.

3. Use only clean hydraulic lines or flush them before installation. (Note chapter7.5

“Performing flushing cycle” on page 38 when you flush out the complete

system.)

4. Connect the lines in accordance with the installation drawing and the machine

or system schematic. Check whether all ports are connected or plugged with

threaded plugs.

5. Tighten the fittings correctly (note tightening torques). Mark all correctly

tightened fittings, e.g. with a permanent marker.

6. Check all pipes and hose lines and every combination of connecting pieces,

couplings or connecting points with hoses or pipes to ensure they are in

condition for safe working.

For relationship between direction of rotation and flow direction, please refer to

data sheet 93221.

Procedure

Loading...

Loading...