Page 7 of 18507388-01 Issue 1504

edion) for installaons in the U.S. or the Canadian Electrical

Code Part 1, CSA C22.1 (latest edion) for installaons in Canada.

See rang plate for correct wire ampacity for the cooling chassis

required, and size wire accordingly.

Thermostat

Install the thermostat according to the direcons furnished with

it. The thermostat must be located on an inside wall where it will

not be aected by dras, sunlight, or any other heat producing

appliances. Connect the thermostat wires to the low voltage

leads on top of the unit following the wiring diagram aached

to the unit. The heat ancipator seng is 0.50 amp.

Air Filter

All indoor return air must be ltered. A permanent-type lter is

furnished with the unit, located directly behind the access panel.

Removing the panel permits access to the lter. See Figure 3.

If an installaon is made in which it is more desirable to mount the

lter exterior to the unit, in the return duct work or elsewhere, the

permanent lter can be used or replaced with a disposable lter.

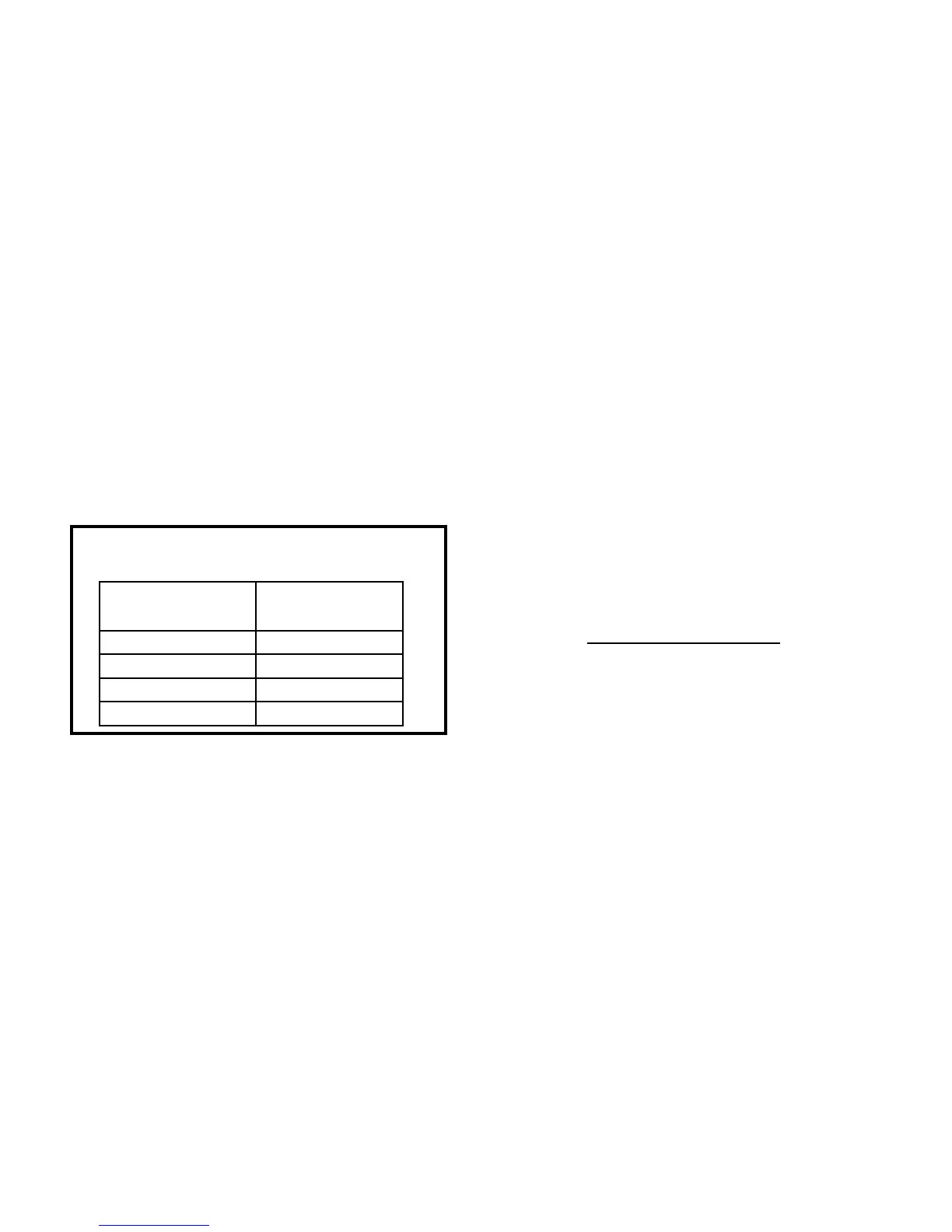

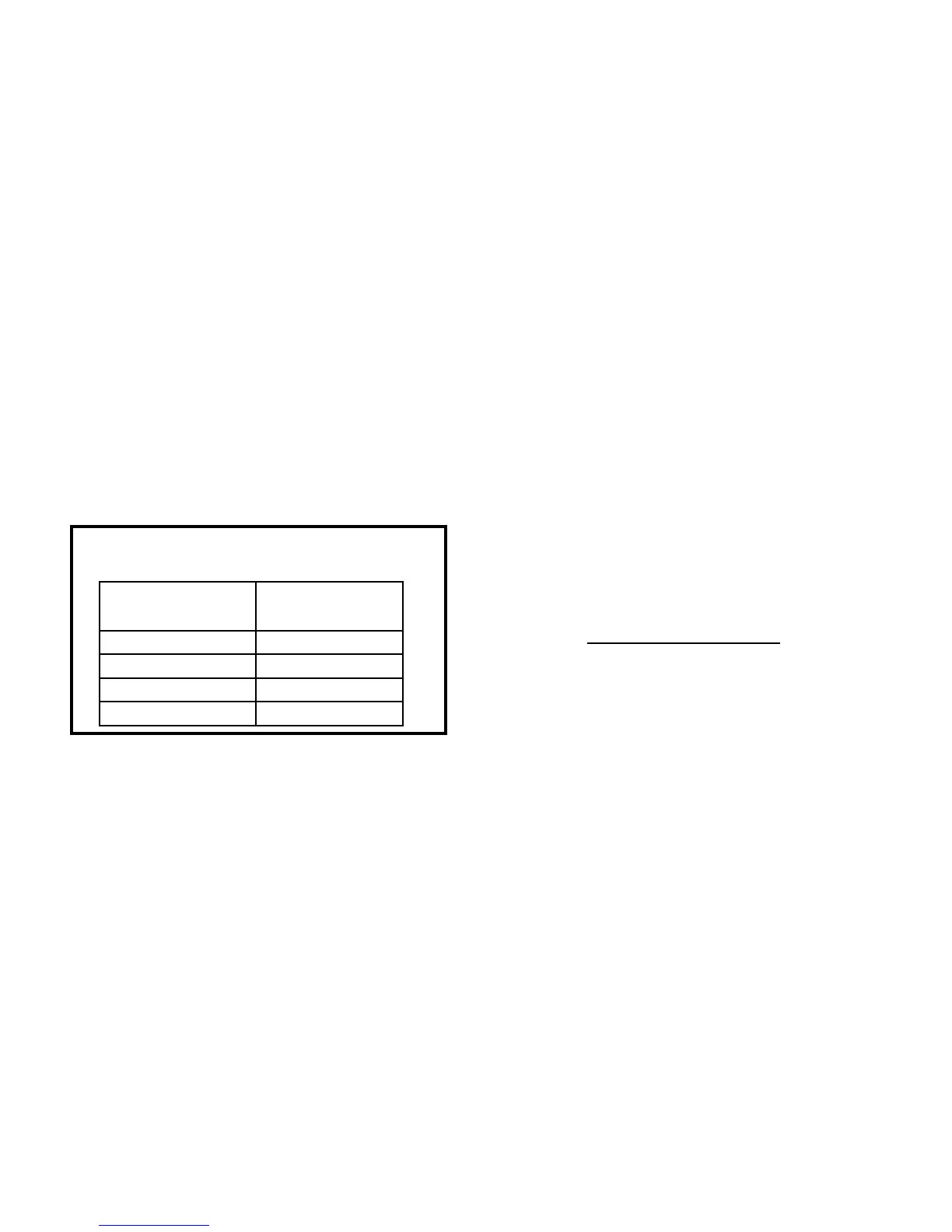

If a disposable lter is used, refer to the informaon provided in

Table 1 when sizing the disposable lter.

Supply and Return Duct(s)

Provide duct(s) sized suciently to handle the larger of the air

volumes for heang or cooling provided by this model.

Connect the supply duct to the top of the unit using canvas

connections or other flexible connections to prevent noise

transmission into the duct system.

To connect the return duct to the system, use a straight piece

of duct 22” wide by 6” deep. Insert the duct into the return

opening in the boom of the unit and ange the duct over the

exisng anges around the opening inside the unit. Make sure

that all sides of the duct are anged over to permit removal of

the cooling chassis if required. Use a exible connecon to aach

the remainder of the return duct. The return duct should be

sealed to the unit casing and must terminate outside the space

containing the furnace.

x

3600

x

=

Cubic Feet Per RevoluonBTU/HR

INPUT # Seconds Per Revoluon

Heang

Value

Adjustments – Heang Secon

Temperature Rise

At me of installaon, the temperature rise must be adjusted to

be within the range specied on the unit rang plate. See table 2.

Pressure Regulator

he gas input must not exceed the gures shown on the rang plate.

The unit is equipped for rated inputs with manifold pressures of:

3.5” W.C. for natural gas and 10.5” W.C. for propane.

The manifold pressure can be measured by removing the pipe

plug in the automac gas valve. Connect a water manometer and

measure the pressure.

Only small variaons in gas input may be made by adjusng the

regulator. In no case should the nal manifold pressure vary

more than 0.3” W.C. for natural gas or 0.7” W.C. for propane.

To adjust the regulator, turn the adjusng screw on the regulator

clockwise to increase pressure and input or counterclockwise to

decrease pressure and input.

For natural gas installaons, check the burner rate by observing

the gas meter (making sure that all other gas appliances are

turned o). The test hand on the meter should be med for

at least one revoluon. Note the number of seconds for one

revoluon.

Adjustments – Cooling Secon (HWC models)

No adjustments are required or should be aempted regarding

any of the components of the cooling chassis. The chassis should

be checked to see that none of the wiring is loose or missing.

Cooling chassis is charged with R410A refrigerant.

Pressure Regulator

Model

Number

Filter Area

(sq. in.)

HWC8-12 300

HWC8-18 480

HWC8-24 480

HWC8-30 480

Minimum Required Surface Area

for Disposable Filters

Table 1

Loading...

Loading...