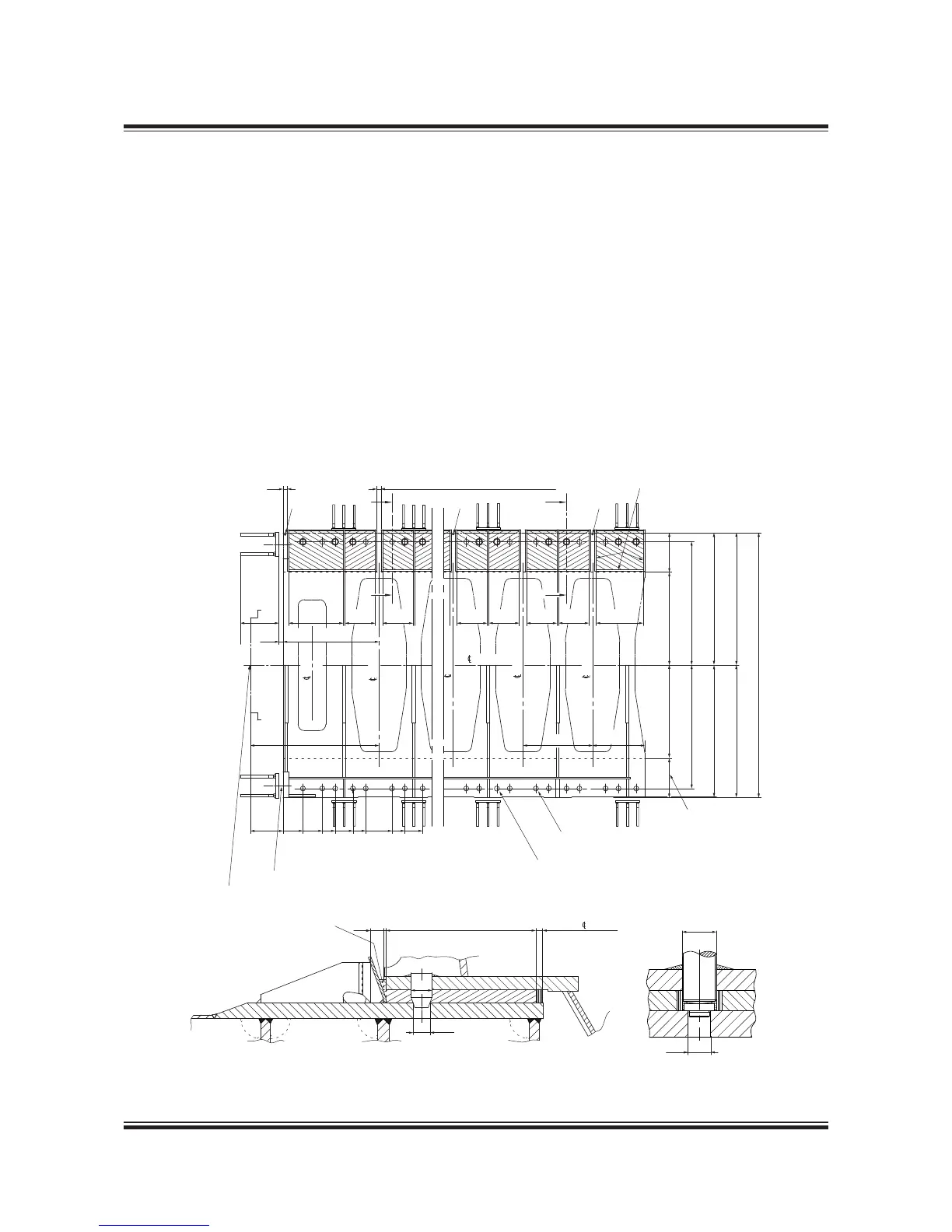

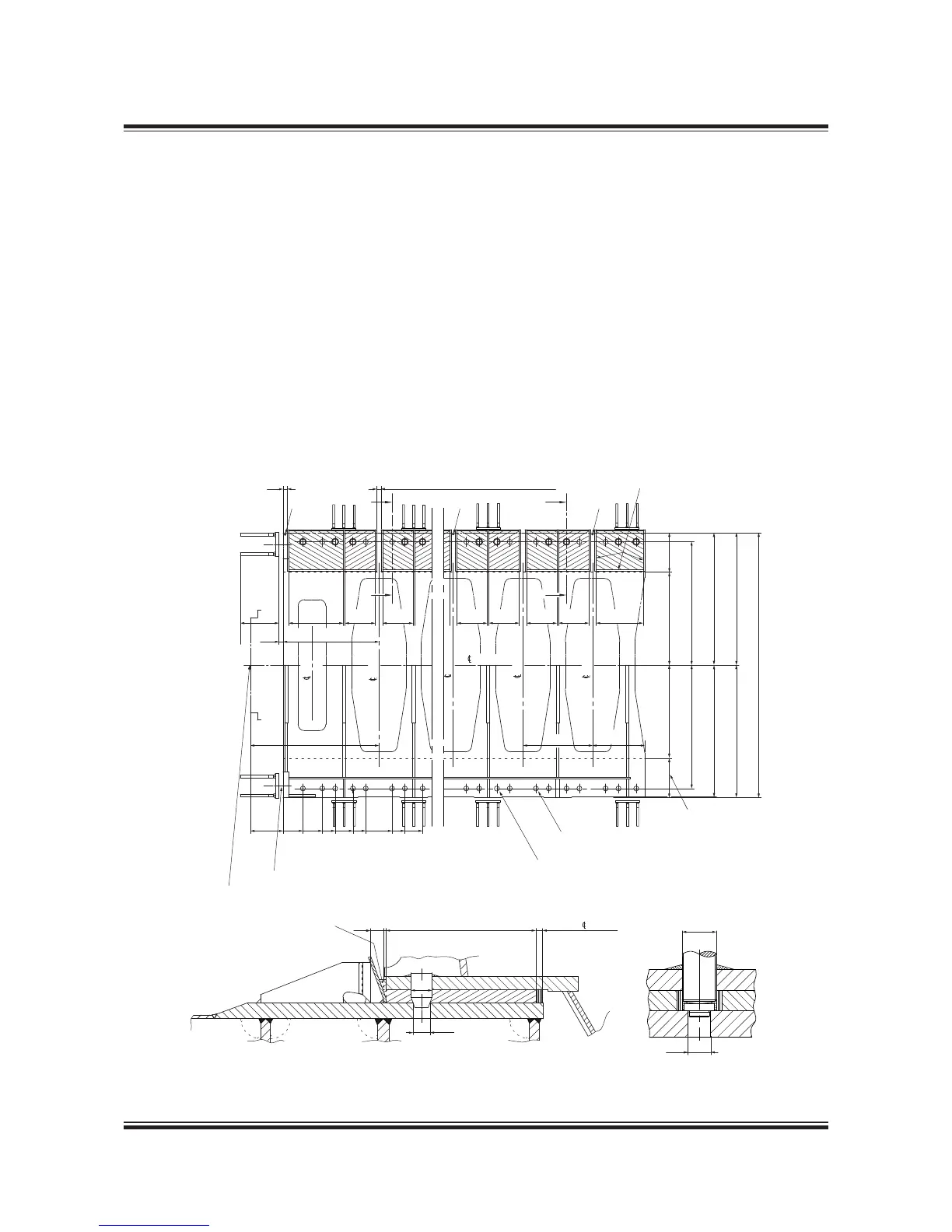

MAN B&W 5.12

Page 1 of 3

MAN Diesel

MAN B&W S65ME-C/-GI 198 87 99-4.0

Epoxy Chocks Arrangement

For details of chocks and bolts see special drawings.

For securing of supporting chocks see special

drawing.

This drawing may, subject to the written consent of

the actual engine builder concerned, be used as a

basis for markingoff and drilling the holes for hold-

ing down bolts in the top plates, provided that:

1) The engine builder drills the holes for holding

down bolts in the bedplate while observing the

toleranced locations indicated on MAN B&W

Diesel & Turbos drawings for machining the

bedplate

2) The shipyard drills the holes for holding down

bolts in the top plates while observing the toler-

anced locations given on the present drawing

3) The holding down bolts are made in accord-

ance with MAN B&W Diesel & Turbos drawings

of these bolts.

#

25 mm thick dammings

2x1 off ø78 holes

M85x6 holes, predrilled ø79, in the

bedplate and ø64 holes in the topplate

ø79 holes in the bedplate and

ø64 holes in the topplate

'PFǤCPIGQHthrust shaft

65 mm free spaces for supporting wedges

1,084

812

0

310±1

612±1

812±1

1,088±1

1,288±1

1,696±1

1,896±1

2,172±1

1,920±1

2,052

2,062

4,124

1,920±1

2,052

2,062

730472472472472472472848

149265

600

65

508

2,000

615 1,447 1,447 615

ø64

ø79

251050

Effective 560

Epoxy wedges to

be chiselled after

curing to enable

mounting of side

chock liners

The width of

machining on

the underside

of bedplate

1,467 to

engine

A-A

B-B

B

B

A

A

##

thrust

bearing

cyl.1

cyl.2

cyl.3

Engine

aft cyl.

M85x6

ø64

Fig. 5.12.01: Arrangement of epoxy chocks and holding down bolts

078 88 96-7.0.0

Loading...

Loading...