MAN B&W 7.04

Page 3 of 3

MAN Diesel

198 67 68-4.2MAN B&W 98-60MC/MCC/ME/ME-C/ME-B/-GI, S50MC

Engine Selection Guides

Fuel Oil Pipe Heat Tracing

178 50 625.0

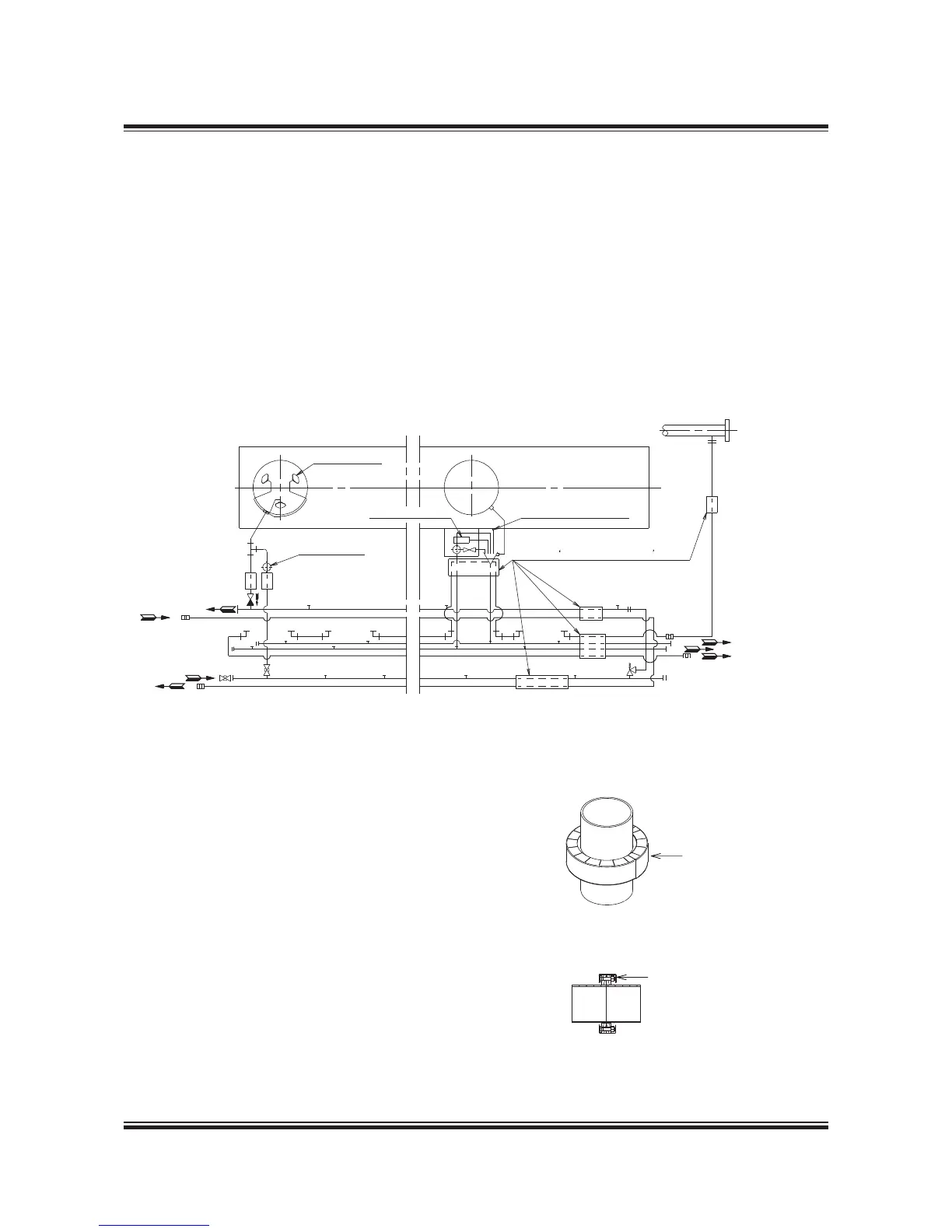

Fig. 7.04.03: Fuel oil pipe heat tracing

The letters refer to list of ‘Counterflanges’

!&

!$

"$

"8

"&

&

8

&UELæPUMP

3HOCKæABSORBER

&UELæVALVE

$RAINæCYLæFRAME

3EEæDRAWING

&UELæOILæPIPESæINSULATION

,

&RESHæCOOLING

WATERæOUTLET

#YLæ

The steam tracing of the fuel oil pipes is intended

to operate in two situations:

1. When the circulation pump is running, there

will be a temperature loss in the piping, see

Fig. 7.04.02. This loss is very small, therefore

tracing in this situation is only necessary with

very long fuel supply lines.

2. When the circulation pump is stopped with

heavy fuel oil in the piping and the pipes have

cooled down to engine room temperature, as

it is not possible to pump the heavy fuel oil.

In this situation the fuel oil must be heated to

pumping temperature of about 50 ºC.

To heat the pipe to pumping level we recom-

mend to use 100 watt leaking/meter pipe.

176 94 23-4.4.0

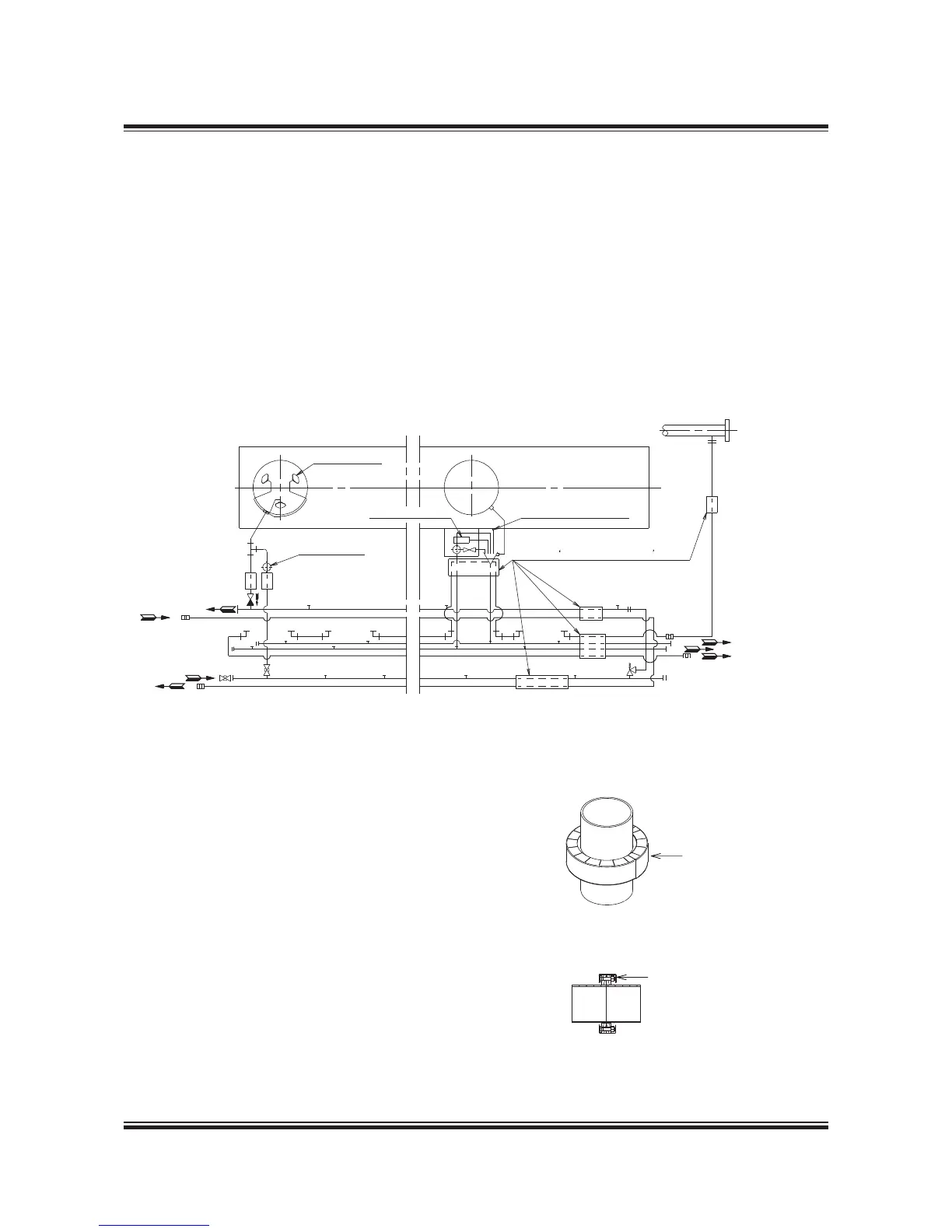

Fig. 7.04.04b: Spray Shields by clamping bands

To fulfill IMO regulations, fuel and oil pipes assem-

blies are to be secured by spray shields as shown.

To ensure tightness the spray shields are to be

applied after pressure test of the pipe system. as

shown in Fig. 7.04.04a and b.

To avoid leaks, the spray shields are to be in-

stalled after pressure testing of the pipe system.

Fig. 7.04.04a: Spray Shields by anti-splashing tape

Fuel Oil and Lubricating Oil Pipe Spray Shields

Plate 0,5 mm. thickness

Metal flange cover

Loading...

Loading...